OK, it is the eccentric crank(s). Now I just have to get them adjusted. Is there a good process to follow?

JP Thut

Yes

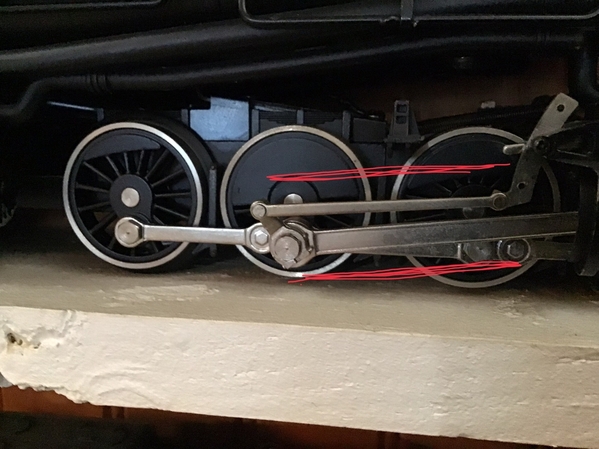

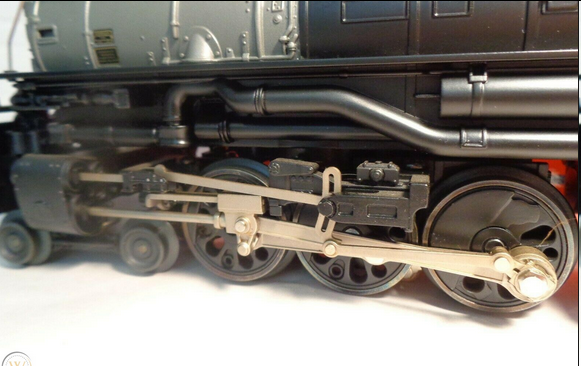

#1 remove the screw entirely, pull out the end of the eccentric crank and examine it for damage from being run loose. Specifically you are looking at the interface into the wheel which is what clocks it (clocking- like hands on a clock)- the angle or position compared to the wheel. Most types have 2 little protrusions that then fit into matching holes or pockets in the wheel to prevent rotation and align to a very specific position (again, pivot point near the center of the wheel). If run loose, that will get sheared off or damaged and thus no longer reliably hold in the correct position.

but the end we really worry about is the tips

but the end we really worry about is the tips  or another style

or another style

If those are damaged or sheared off/ rounded off, then replacement is the best long term option to prevent further damage.

Parts list for your engine. https://www.lionelsupport.com/...LOCO-ONLY-6308014001

You have 2 left hand and 2 right hand ones, for the front and back cylinders

https://www.lionelsupport.com/...Y-RH-LM-CHALLENGER_2

https://www.lionelsupport.com/...Y-LH-LM-CHALLENGER_2

#2 if the parts are OK or you get replacements, then you simply insert them and line them up, then I typically put a drop of thread locking compound on the screw before threading it in and locking in place.

#3 Last lubricate all this moving assembly as the worse thing now is brand new parts with no lube shearing it off again from binding and grabbing.

Again, what happens if these are ever run with the screw even slightly loose, the rotation of the wheel tends to beat the little tabs into total destruction allowing the eccentric crank to pivot back and forth, each time more and more while it loosens the screw. This eventually jams the wheels and can result in major damage- not to mention motor burnout if someone keeps trying to move a binding engine. It's a self destructing failure where simple looseness starts it off, but running loose then cascades into total destruction rapidly in a very short time.

but the end we really worry about is the tips

but the end we really worry about is the tips  or another style

or another style