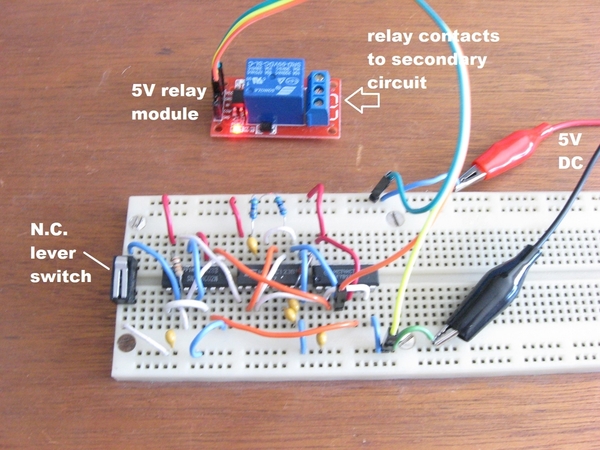

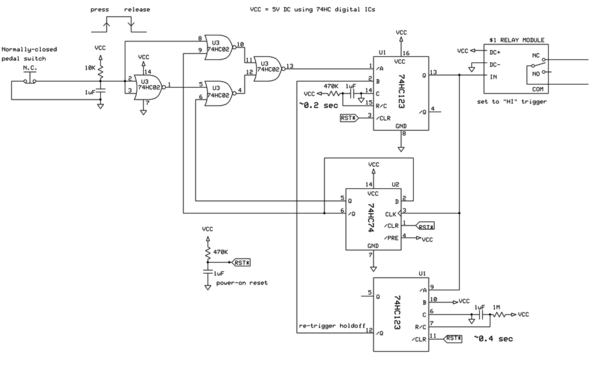

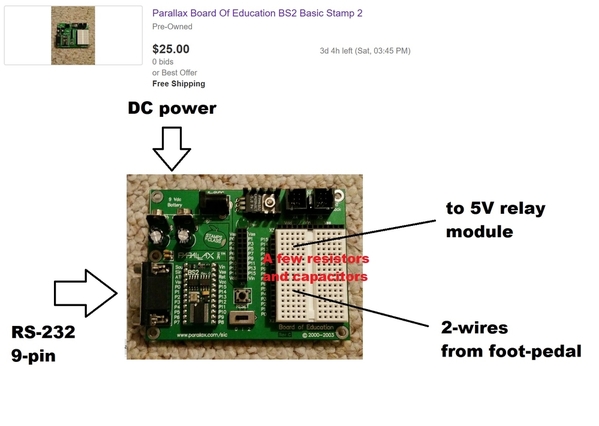

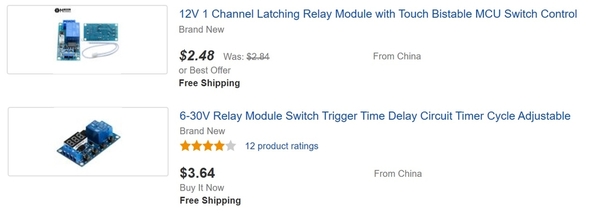

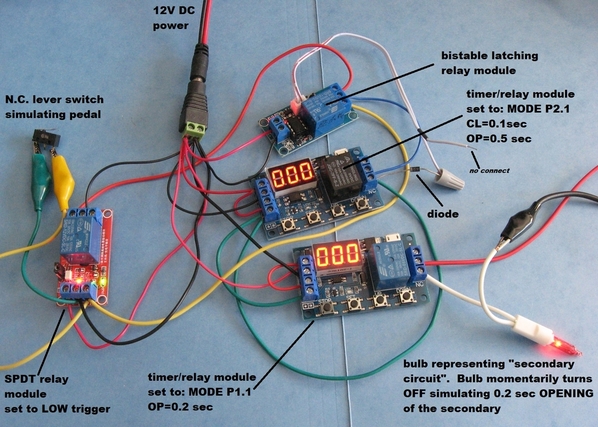

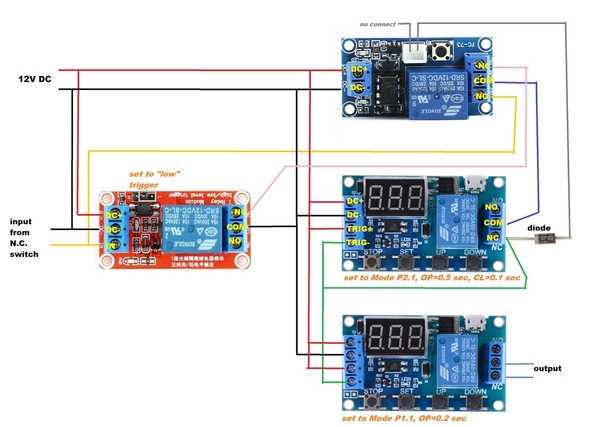

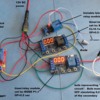

Ted: That's great! So our starting point is something like this:

I think that will help to make this project a bit easier to implement.

But I think we need to clarify some operational details that I'm not sure I learned from the previous parts of this discussion. So let me ask some questions.

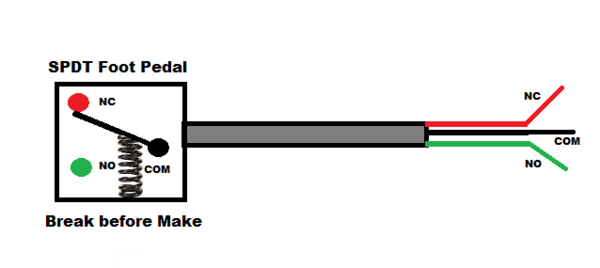

If a train is moving forward to begin with, the initial depression of the pedal will put it in neutral and it will stay that way until the pedal is released again. And if the train is initially in neutral, the first depression will put it either in forward or reverse depending on the part of the e-unit cycle that is currently engaged. There is no feedback on direction so we don't know what state the e-unit is in at the start. Do I have that correct?

Do you plan to have it in a known state to begin with? If starting in neutral, you can go forward or reverse as long as you hold the foot switch down. Let it up and the train returns to neutral. Is that the desired operating situation?

Also, will you need to be able to change the operating cycle to the opposite state? That is, if neutral is the normal starting state, will you need to be able to change it to the other way around; as in foot switch not depressed, train moving forward?

And remember, you only get one chance to create a good first depression. ![]()