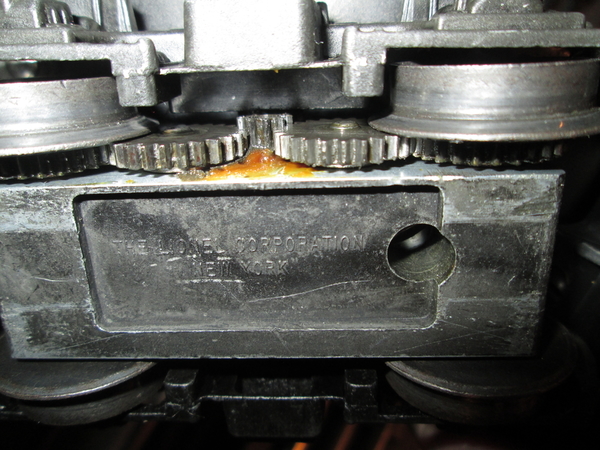

I love modifying stuff ..! along the way I found a guy that also likes to modify stuff..! that happens to be a machinist / train guy..

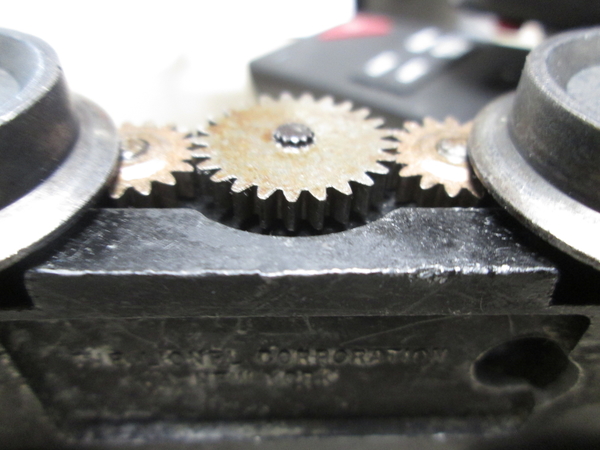

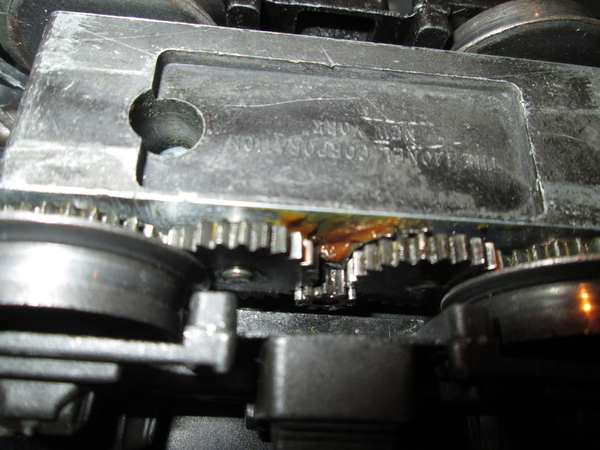

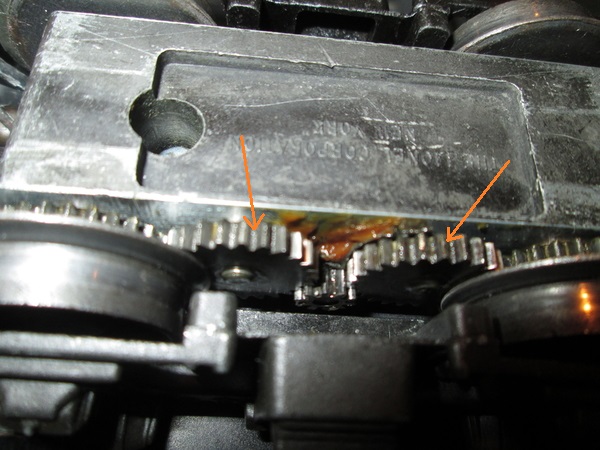

He re machined the power truck for a GP to have the center gear small with two large gears next to the magnet-traction axles..

All I can tell you is its a stump puller ! going up my grades at ANY speeds is a nothing to do . with my grades you can set it and enjoy a totally different experience I have never seen.

With that said is this something that has been done before? or has any manufactures done this with their power trucks..

Later when the layout is ready to video I will show my GP with it running...

it is the perfect balance of slow and normal running speeds but the slow is amazing..