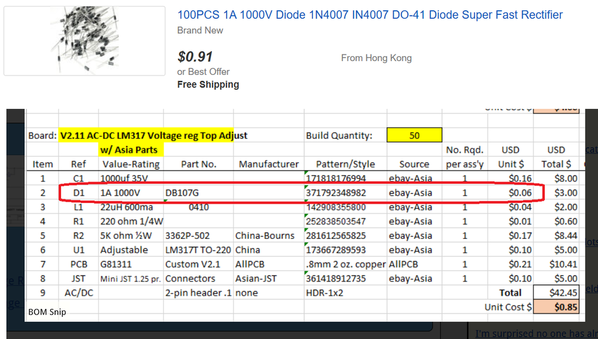

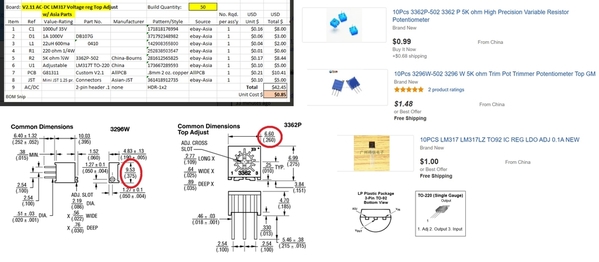

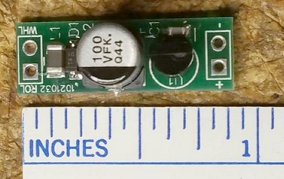

Several months back I posted an adjustable output voltage regulator board based on the LM317T IC, here. A few days ago I was contacted offline by a gentleman who wanted the same board, but narrow; only 1/2" wide. I made a version for him and ordered a dozen of them shipped to him direct. I thought I might as well post the build files here in case others may have need for an extra narrow regulator board. Costs are about $5.00 each for all domestic boards and parts; or about $1.00 each for offshore components.

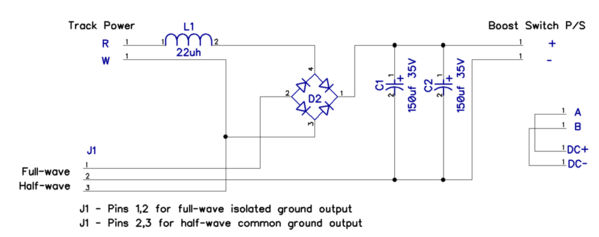

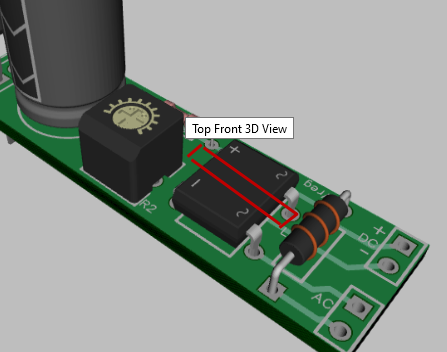

Here is the circuit and a 3D depiction of the completed board. It uses all the same components as the previously posted board, above. The circuit is identical.

The User Notes in pdf form and Gerber zip file are attached below. The BOM is identical to the earlier board.

Have fun, Rod