Originally Posted by Bob:

If I was doing the job again, I'd install twice as many LED's with shades and the light output would then be adequate.

This is one of those you have to see it for yourself to appreciate the wisdom of this comment. Whether it be from adding more fixtures or using brighter LED's, this has been my experience when lighting up a wide variety are structures if you want the viewer to see interior detail. Not all 3mm LEDs are created equal and I sometimes wonder about the claimed intensity (millicandela or mcd) specs on eBay listings. Bottom line is you need to experiment a bit to insure you have enough brightness.

I think you want to be able to look through the doors and windows and see detail:

For whatever reason I've found you need MORE interior brightness than you'd think when shooting photos/videos than when seeing it in person. So take test photos like above so the rest of us can appreciate your handiwork!

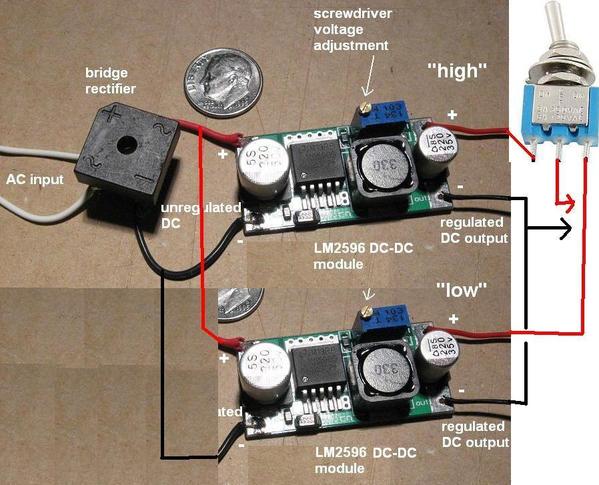

If you haven't messed with these voltage converter modules, something that's not obvious is the screwdriver adjustment is multi-turn and it can take several turns using a tiny jeweler's type screwdriver to change the voltage by even a few volts. This can be tedious. Well, you look like a young guy in your video so it's probably no big deal but for us old folks with tired eyes...  And while you can replace that trimmer potentiometer with one with a bigger knob or whatever, another idea is to have multiple modules. Using the miracle of "cut and paste" here's how a single bridge rectifer ($1-2) could feed two (or more) DC-DC modules which run $1 each on eBay. For example, a 2-position switch (SPDT) can select between pre-set high and low voltages from two modules.

And while you can replace that trimmer potentiometer with one with a bigger knob or whatever, another idea is to have multiple modules. Using the miracle of "cut and paste" here's how a single bridge rectifer ($1-2) could feed two (or more) DC-DC modules which run $1 each on eBay. For example, a 2-position switch (SPDT) can select between pre-set high and low voltages from two modules.

And to egg you on a bit, what I'd really like to see is at least one of your stalls animated to open/close its doors. There was this recent thread asking how to animate Korber RH doors and I excitedly cobbled together one suggestion with video on how it might be done but never heard back. But as GRJ will remind me, Nothing is so easy as the job you imagine someone else doing!