I finally got a little space allocated to build a layout, for the past 6 years I set up in the garage before Thanksgiving and tear down after Christmas, my collection of stuff has grown over the years. It's a vacant bedroom, only building space I see is along two walls in a C or L shape. I mainly have Lion Chief Plus running on Fastrack O36, Id like to have a larger radius but don't know if I have the real-estate. I have some O48 and O72. I recently bought the Mohawk Pacemaker set which requires )54, but I currently run it on O36, slowly allbeit. Its on a track up high on the wall 12" below the ceiling. Feel free to chime in on my options with the space I have. Ideas I've thought of, are two loops interconnected with and elevated loop thru a corner tunnel, maybe a lift bridge. I understand the radius requirements of the curves just don't know how to make it all come together. Thanks for input. (see pics)

Replies sorted oldest to newest

So much to talk about on your post but I have to ask, the Mohawk really works on O36? I wanted one but held off because I only have O48 curves. If you are able to run it on O36 I'm mad at myself, it is impossible to find one under $2,000 now a day so I missed out on that gorgeous engine.

Because it’s elevated I’ve only ran a a slow speed I couldn’t wait for a full layout to be completed I got the red one by far the most I spent so far but I preordered.

Looking at your dimensions, i would suggest that you only pursue an 072 mainline if it does a four-wall loop. You'd have to have a lift-out or hinged bridge in front of the doors, but that would work very well.

I would say your other option would be an 054 mainline dogbone. Each dogbone would circle back before reaching the doors, then travel around the walls. This would leave an empty walkway space in front of the doors. You could easily make this a double mainline or have two levels with this plan.

Me personally, i have an 0-36 layout which is basically a dogbone with each end stacked to create two levels. Trains start in one dogbone (where a staging yard is as well), go around the room, do a U-turn, climb into the mountains, and go into the other dogbone on the second level, right on top of the first. This design is fairly common for HO layouts. Just make sure you stick with a grade well under 4%.

I would also recommend not using FastTrack for a permanent layout. Quality control, especially on the switches, is very bad. Gauging and connection in between track pieces can also be flawed. I regret using it on my layout - my higher-end engines hate it.

Hope this helps! let me know if you have any questions, I'd be happy to help.

My suggestion would be to increase the size of your elevated corners to be able to use at least O54 curves. If that engine ever "stumbles" just a little bit on your O36 curves (maybe by just running over an errant spider), it may fall to the floor and you can just imagine what that might cost to fix. If you choose not to do this, then run something else up there that's capable of O36 curves.

Chuck

Thanks Chuck, believe me when it makes a short trip I’m right there under it fearing what you said would happen, it’s temporary for now .

I'm with Chuck, I wouldn't be running an expensive locomotive rated for O54 on O36 track, especially way above the floor!

Thanks John, I didn’t think the O72 would be an option, I’ve seen some dog one layouts that might work, I’m gonna draw a few ideas up and post them for comment.

im kinda tied to the fast track system because of my current inventory My model RR is semi permanent and a hodgepodge of accessories. I had used a buss line to feed the track before and yes switches are poor quality. Thanks for your advise, a diagram of your suggestion would help.

Tom

I think the ceiling track could easily accommodate at least O42, and with a little extension in the corners, O54.

Apparently i cant figure out how to reply to my original post, if this only goes to GRJohn, I apologize. I've attached two options for my tablework, Option 1 is best because Id like to stay away from the windows, Option 2 goes across the windows which gives me more table area. What I was hoping to get input for for a design and what radius would work. I made the table widths 40" to facilitate O36 loops, I've got to use my Fastrack, I have trestles and graduated trestle. Planning a lift out bridge to fill the gap. If someone knows who regularly designs layouts Id appreciate the help. THKS

PS I moved the Mohawk to the safety of my Snyder Shelves until I can run them safely..

Attachments

With an around the room layout like that, I still think you're really limiting yourself with O36 curves.

Ok thanks for your input

Just remember in your planning, when you run track next to a wall, you have to leave about 3 inches between the edge of your track and the wall. Why? Because every piece of equipment that runs through a curve near a wall will extend way out over the track, especially with O36 curves which are very tight. Allowing the 3 inch "gap" protects both your equipment and your walls.

Chuck

Thanks Chuck

I would narrow the tables, 40" is a stretch to reach a derail car or do track maintenance.

Do to size of the room and desire to run O54 I agree with John M 43 comments.

If it was me, I would run around all 4 walls with the control panel just inside the door to the room or inside the layout. You could add a movable section if you want to "squeeze through" to get inside layout, if you don't want to duck under. Something often not thought of is making the table height about 4 feet. It is convenient to work on, gives more realistic view of the railroad, "not flying over it", and is much easier to duck under. I would put a bridge in front of the window (does NOT have to be movable). Actually could look very nice, allow you to still open and close the window and not block light. - Jim

You can do a manual entry bridge, here's the one that I have entering my freight yard. It's a simple hinged bridge and it's aligned on the opening end using a couple of brass locating pins.

You can also go Cadillac and go for something like the Mianne power lift bridge. ![]()

Attachments

Couple of comments. First is laying out your plan on the floor is a good idea since it will help work out the unexpected kinks. I kept mine on the carpet for nearly two years and went through many modifications. Now I've mostly settled on the track plan, the bench work will be made fit to the track rather than fitting track to the bench work.

Second is about the required radius listed for a particular locomotive. My legacy ES44AC had what I thought was conflicting radius information, the Lionel website says minimum 056 while the manual says 036. My test layout was 048 and the ES44AC did indeed run just fine on that radius, however when coupled to some freight cars that first car would ride up off the rails and while it didn't quite derail it wouldn't take much.

I know I new to comment here, but from what I have learned is go with the biggest curve you can. I had the same problem as @Mike in NC with my MTH ES44AC. Said it would work on 054 but like above the first car behind the engine would ride up off the rails. I went with 072 and really like how it looks and rides.

Thanks for the suggestions everyone!

I will agree with the others, put in one track of 072. My room is almost the same size as yours, and I settled for 054. If I was to do over, I would go with 072. Since it's late. I'll just say to look at my layout design and build topic in my signature line. I'll get back to this n the daytime. I have lift up bridges to get to the center and my benches are all 30" deep so I can reach to the back.

Ive gathered many ideas from everyone. Im gonna build around the room with a lift bridge access the middle and narrow all tables to 30" to 36" if someone could direct me to options to get some one Ito actually put down a track plan on paper with inventory requirements of Fastrack that I can build off of. I can build my tables first then design a layout, but better to have a layout design first. Trying to hook up with someone who can do layout CAD work or something similar. Thanks

There are many people here willing to help, but you have to give us at least an initial "blueprint" of what you would like to see and some idea of how you intend to operate (e.g. just run trains around an oval or run more like a real railroad). Also, using O72 curves, as most here are recommending, with rooms this size, you are only going to have 5ft or less of straight track on each side of the room (less on the 10ft walls). Will that be enough for you? Try laying out six pieces of 10" straight track on the floor parallel to the wall to see if that works for you.

Finally, as others have said before, FasTrack is really a hinderance to layout design because of the limitations of its available curves and its available switches. If you go that route, are you willing to cut FasTrack pieces and then do the modification work to make your "new" dimensional pieces work again?

Chuck

@Tzer58 I said I would give more detail. Here it is. I started a topic like yours at the beginning of 2017. We went through 4 plans. The first died on the drawing board. I started building the next two, but saw they weren't going to work, so I settled on Plan D in early 2020. A couple of Forum members helped me out in particular using SCARM, a free CAD package until you hit a certain number of track sections on the drawing board. Then it asks for money, but it is reasonable. Here is a picture captured with Paint. The upper level is green, the lower level is blue, and the 4% grades are purple. My layout is a twice around, over and under with some spurs, two passing sidings, a tiny yard on the lower level in the upper right peninsula, and a wye leading to a two stall enginehouse on the upper level in the upper right. The room is 11x11, the layout is 11x8 if you don't count the 2-foot peninsula in the upper right. There is a lot packed in, but it works.

The yellow space in the middle indicates a lift up bridge section. Since the two tracks are 6" different in elevation, I used a method that I first saw @mike g. use on his layout. It uses a linear actuator to lift both bridges with the flip of a switch. I used GarGraves track and Ross Custom Switches. You can tell I used a variety of building materials, cleaning out all the old wood I had and purchasing very little new. Here are some recent photographs.

These date back to a year ago.

Attachments

@PRR1950 posted:Finally, as others have said before, FasTrack is really a hinderance to layout design because of the limitations of its available curves and its available switches. If you go that route, are you willing to cut FasTrack pieces and then do the modification work to make your "new" dimensional pieces work again?

There are pros and cons, IMO. Fastrack isn't all bad and there are plenty of examples of great results on a permanent layout. Thinking of a Chris' layout (RBP Trains) and Sean's layout (Sean's Trains) as some prime examples. I believe they're both members of the forum but I don't have their user names handy.

@Ken-Oscale has created and shared numerous track plans on this forum using Fastrack, so you have a lot of reference there as well.

There's a lot you can do in an 11' x 10' space, even if you want at least one line to have 072 curves. I'm thinking a once or twice around 072 mainline on the outside with a smaller radius line inside that. You could potentially even put a set of overlapped reversing loops in one corner to give the layout some more operational interest.

I agree with other comments - you need to think about and write down a list of what you want out of your layout. Consider what you're willing to compromise or give up as it's very unlikely you'll be able to fit it all. Then folks on the forum might be able to better help you come up with a track plan.

@Mike0289, in order to make your stacked O72 FasTrack reversing loops work in one corner of this room, the "upper" and "lower" mainlines are going to have to meet somewhere in an O72 turnback curve in another part of the room unless you intend for a freight yard somewhere in the room to provide trains for both reversing loops separately. If you try putting 2 O72 circles right next to each other, you will see that you need at least 156 inches (13ft) to allow some room for roadbed and avoiding sideswipes on the nearest curves. In an 11ft (132 inches) room, this just isn't going to work.

Now, if @Tzer58 were willing and able to drop down to FasTrack O60 curves, your ideas might give him some options, but will still leave him with very little straight track. I will wait to here how he plans to operate before making any more comments.

Chuck

@PRR1950 posted:@Mike0289, in order to make your stacked O72 FasTrack reversing loops work in one corner of this room, the "upper" and "lower" mainlines are going to have to meet somewhere in an O72 turnback curve in another part of the room unless you intend for a freight yard somewhere in the room to provide trains for both reversing loops separately. If you try putting 2 O72 circles right next to each other, you will see that you need at least 156 inches (13ft) to allow some room for roadbed and avoiding sideswipes on the nearest curves. In an 11ft (132 inches) room, this just isn't going to work.

Now, if @Tzer58 were willing and able to drop down to FasTrack O60 curves, your ideas might give him some options, but will still leave him with very little straight track. I will wait to here how he plans to operate before making any more comments.

Chuck

I didn't say it very clearly but what I meant was stacked reversing loops of a smaller radius inside the outer 072 line. Probably still wouldn't leave much interior space, though.

Now I understand.

Thanks again for all the comments. My new layout diagram shows what the O72 loop looks like, that pretty much maxes out my space with the table layout, including lift out bridge. I only have the one locomotive requiring O54, the red Mohawk, all my other locomotive are LC2 and all run fine on O36. I'm not opposed to reducing curves to O60 or O48, creating the most straight runs would be ideal.

With limited space and a layout that will probably have to be moved in a couple years its kinda temporary in a way. At this time I need to stay with the Fastrack, I understand the limitations, but as Mike0289 mentioned RBP trains, Seans trains, or Ken-Oscale those layouts look great for what I'm doing. double dog loop, I guess from what I've read that's reverses your direction with out backing. I see a lot of long layouts on the floor, but with two knee replacements its a bit difficult for me.

Wants and Wishes, wow, these are features I and probably everyone likes, I cant have it all> Passing siding, spurs for train storage and action car accessories, ie: barrel, lumber, Milk, cattle are just a few I have and the grand kids like to mess with those, possible grade and bridge, I thought a two layer mountain tunnel would work some how in the right corner. Placing some buildings around, from Plasticville , MTH, and Menards I have.

In my layout diagram have have some O36 down just to think about it. I'm flexible just need help with a design and track requirements. I will continue to look at sites and build suggestions, a lot a great ideas and layoutd are out there. Mark Boyce has a nice layout thanks for the pics and info.

Attachments

It looks like the track is too tight against the window wall and engines will hit the baseboard on both sides.

Shift everything over if you can or just swap a 10" straight on each side for a 5" plus a 1 3/4" pieces.

I agree with Richie about shifting the track away from the window wall. Taking into account the engines you have and the short time you will have this layout up and running, the tighter curves will serve you well. You will then be able to decide if you want broader curves on the next layout. I'm glad you took a look at my layout. Thank you. I am thinking this layout may be my next to last layout, since we plan to move to a single story home when my mother-in-law passes on or has to go to a home. Right now she lives across the road. The way she is going, she may outlast Kim and me, and this will be my last layout. ![]()

Works like a chance!

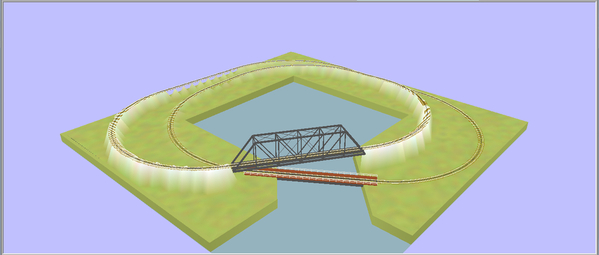

With an around-the-walls layout, I would recommend going with at least O-72 so you'll be able to support ANY 3-rail equipment you might encounter. Leave about 4" clearance between the track center and the walls for that bargain Big Boy you get down the road. The triangular design shown above would work nicely using O-72 curves. You can even do a two-lap oval.

Attachments

Regarding my initial idea of a O72 loop around the table, then installing a 060 or O48 loop inside that, my question is about turnouts, would I use o72 switches or O60, does it have to match the loop, what are the factors to consider?

What is meant by “compound curves? On a curve are different radius or straights used in the curves

thanks Tom (tier)

Attachments

On my small layout I have an O42 outer loop with an O31 inner loop, they are connected by O72 switches. On my O31 loop I have a small 2 track yard inside the loop that uses O42 switches. As you can see any size switch can be used as long as it's not part of the curve.

Going by your room drawing I thru this together real quick. It has 060 min. curves, 072 on the outside loop. All switches are 072.

Don't really like the thru track yard, but not sure what you want exactly. Could replace it with a non thru yard with longer spurs.

Here is the XtrackCAD file, this program is completely open source and free to use, and is available for all operating systems.

Attachments

@Tzer58 posted:Regarding my initial idea of a O72 loop around the table, then installing a 060 or O48 loop inside that, my question is about turnouts, would I use o72 switches or O60, does it have to match the loop, what are the factors to consider?

What is meant by “compound curves? On a curve are different radius or straights used in the curves

thanks Tom (tier)

Assuming you are talking about switches for crossovers on the straight area between the two loops, no - they don't have to be the same diameter as the curves. In general, which switches you use has more to do with the spacing/distance between the two tracks where you want the crossover to go. The larger diameter switches like O-72 result in a smaller distance between the tracks while a smaller curve like an O-36, results in a larger spacing.

In addition, using larger switches like O-72 results in a smoother transition for the train crossing between the tracks as the curvature is not as sharp. I would say O-72 switches are common for this purpose because they take up less space and give a smoother transition. Those are the primary factors.

If you plan on keeping the tracks separately powered you can also install a FT 1 3/8 "fitter" piece between the switches with the wire underneath disconnected.

I would recommend that you obtain a copy of the Lionel 2016-2017 Track and Power catalog - check their website - which gives all the distances and spacing for using different switches.

For our purposes, compound curves are generally meant to indicate a large curve made up of different curved sections of track. For example, if for space reasons, you can only fit in an O-36 curve, you may be able to ease the transition from the straight into that curve by using a large diameter curve, like an O-48, on the first and last sections of the curve. That will ease the transition of a train into and out of a curve to help prevent derailments, shorts and possibly running a larger engine.

Similarly, if you need to widen a larger curve slightly on an outside loop (like an O-36 curve) in order to fit a smaller curve (like an O-31 curve) on an inside loop, you can insert a small straight (like a 5" piece) in the middle of the outside O-36 curve. For example, if you have a 4' X 8' sheet of plywood for your layout, you can fit an O-36 curved outside loop (width-wise) on the sheet, but there is not enough room to fit an O-48 curve. If you wanted to run an O-31 loop on the inside, you could insert a 5" straight piece in the middle of the O-36 curve which would give enough room to fit the O-31 loop inside and still fit the O-36 loop within the 48" width.

Darrell, thanks for taking the time to design a preliminary layout, I do want longer dead spurs but that gives me something to work with Im starting with that O72 outer loop, most of my stuff runs on O36.

Richie, thanks for a great explanation of differnet curve radius and compound curves. I will send more pics as I progress and sit down with xtrac CAD or SCARM

The 036 stuff looks awesome on 072 BTW, I have an idea for the spurs, will work on it and see how it looks. How many spurs/sidings are you looking for?