I know that I'm sticking to O72 for the mainlines, I don't know in this space if I can reasonably expect to have larger curves. There will doubtless be tighter curves in the mix as well, but I'd like to leave the maximum flexibility I can for running all my equipment. ![]()

Hi John, a quick question if you have the time. 25 messages a day is a lot for you to deal with. Tim has my check and I'm on the list. What was your approx. wait time from getting on list until boxes at your front door? Our rooms are about the same size. Thanks John for your time.

Tommy

Tommy, it took a while. ![]()

I sent my original layout dimensions to Tim on 6/19/18, it took him a while to respond, and on 8/3/18 I officially placed the order. I received the benchwork on 11/21/18.

Remember, Tim was moving his shop during that time, so I suspect he lost at least a month there. Having recently moved, I can attest to how much trouble it is to get everything sorted out. ![]()

Keep up the good work GUNS!!!!![]()

Thanks Gunny, Yes, I first contacted Tim during his moving process. He asked me to contact him later. We did just that. Layout design, Room size, height, etc. was forwarded to Tim in his time frame. A week or two later I got his BW design back, all my questions answered and of course a bill. Upon remittance, I was told that I on the list. Gunny, I appreciate your time and effort.

Tommy

Hi John H.

I just ain't too bright at all. I should have thought to do that. You're so much smarter than I am.

My best regards.

Tommy

I apologize.

gunrunnerjohn posted:Tom has a tendency to make complex woodworking look easy.

It looks like he has more clamps on that corner than I own!

I try to make electronics look easy, but I'm not capable of making complex woodworking look easy.

You are not kidding on either count here! I have already given up on my woodworking skills. I will never be a Tom Tee, his bench work looks like fine cabinetry or furniture, great work! He has some really neat ideas too.

Now I'm trying to keep up with you on the electronics part and it's still quite a struggle! Will never be a GRJ either, but I am at least learning something and it's fun! Wood is also much heavier than the electronic parts and I am old and worn out, so that helps too. ![]()

You guys really do make these things look easy! That is until I try it myself... ![]()

One more step along a fairly long road. Got a bunch more assembled, took a little more time as I changed my plan a bit so I had to ad-lib a bit on the assembly. All that's left is the 12 feet along the front that will have the lift-gate in the middle of it. I originally started with the lift-gate on the left, but it works better in the middle.

Attachments

Hey John

lots of progress , looks great !

Alex

Really taking shape now, looks great. Looks big too!

What did you change from the original plan? Just curious to see what was involved/how difficult changing things were from original plan? Your cross pieces look a bit different than mine, especially the lower ones. I had some angles ones on the lower parts.

I have some changes to mine coming up one of these days too, but I am going to have to order more stuff for the changes/additions.

Alex M posted:Hey John

lots of progress , looks great !

Alex

Thanks Alex, can't wait to get it all together and see a train run! ![]()

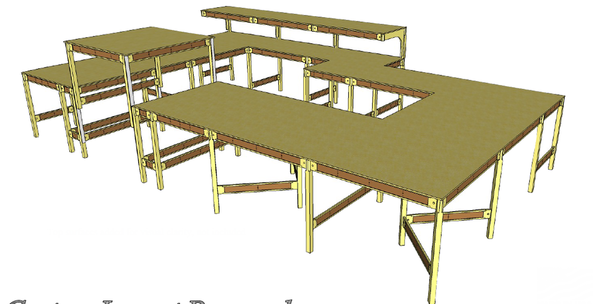

Tom, I am moving the lift-gate about three feet more centered on the front straight. This will allow my next planned expansion of a yard off the side. Here's what the original plan looked like. I'm removing some of the extra legs in the middle as I want more storage under the bench. The diagonals were only there because he was using some stuff I already had. After seeing the plan, I decided to remove those so that space under there is all open.

Attachments

I am happy for you, GunRunner and know you will enjoy your new table, etc. just like the first toy train you ever received!!!

The fun is just starting. ![]()

John that looks so good I think you should put a coat of paste wax on it

clem![]()

I just want to put some trains on it. ![]()

Off to the home center to get your table top, get the pieces cut at the store. Easier to handle and no mess at home. Another step closer to trains on the move.

How long has it taken you to assemble the benchwork? Was it hard to assemble? Did you have help? Thanks.

Go John, go! And most importantly: Have fun!

Andre

coach joe posted:Off to the home center to get your table top, get the pieces cut at the store. Easier to handle and no mess at home. Another step closer to trains on the move.

I'm going to have some of it cut there, I have some 4x8 pieces that will just drop on as is, those just have to come down the way they are.

TrainHead posted:How long has it taken you to assemble the benchwork? Was it hard to assemble? Did you have help? Thanks.

I probably have 7-8 hours into it. Some of the time was adjusting the plan because I wanted to move the lift-gate. No help required, it's pretty easy to manage one man. The size is 20 feet long by 12.5 on the left and 10.5 on the right. There is a 2 foot jog out in the wall and I just wrapped around it.

GRJ, when you get to laying those 072 curves, check out the clearance gauge Jim Berrett made in issue #276, Feb/Mar 2015, page 85, of OGR. It's made to give you just the right amount of room on 072 curves to accommodate running a Big Boy, that needs a 3" overhang clearance from center rail on the outside of a curve, and a 2 1/4" overhang from center rail on the inside of the curve, if you ever run 21" passenger cars. Thank You Jim for that great article.

Good idea Dave, I'll check it out.

Everyone always wants to run trains John. That is why so many carpets get track indentations. ![]() I myself have some vacuuming to do by the Christmas tree before I pop any trains underneath it. I'm still not sure what I will be running. Maybe a couple different things, lol. Looking great John.

I myself have some vacuuming to do by the Christmas tree before I pop any trains underneath it. I'm still not sure what I will be running. Maybe a couple different things, lol. Looking great John.

Well Dave, I’m content with being like John and waiting on Benchwork to run trains. I crawled on the floor too much before I got into engineering at 51 and chased around rugrats on my knees into my 40s. A nice easy to assemble table is the ticket! LOL

Looks good John. You made an excellent choice with Mianne benchwork. I found it easy to assemble. If I had any questions I would call Tim and he always replied. The system is flexible and user friendly. Hope you have all those beautiful locomotives I have seen on the move soon.

Mark Boyce posted:Well Dave, I’m content with being like John and waiting on Benchwork to run trains. I crawled on the floor too much before I got into engineering at 51 and chased around rugrats on my knees into my 40s. A nice easy to assemble table is the ticket! LOL

Yeah, a table would be nice. I've been on knees, stomach, back, side and sitting of the floor. I'd really like to have a seat at a table watching and operating. I'll have to wait and stay on the floor for a bit still. Someday. ![]()

luvtrains posted:Looks good John. You made an excellent choice with Mianne benchwork. I found it easy to assemble. If I had any questions I would call Tim and he always replied. The system is flexible and user friendly. Hope you have all those beautiful locomotives I have seen on the move soon.

Yep, a happy Mianne customer here.

Two words: no sawdust. ![]()

I still have to test upgrades, so there is a smallish carpet central. It's pretty basic, just enough to do more than run on rollers. ![]() I'm looking forward to when I can get this out of the way.

I'm looking forward to when I can get this out of the way. ![]()

Attachments

It's looking great John. Really nice finished train room. Keep posting, it's great to watch the progress. Is the planned layout all on one track level, or are you planning to cookie cut the plywood and have any grades ?

John, have you got a track plan cooked up yet; just wondering? Looking good so far. ![]()

Rod

I'm planning on some elevated track, but I won't be doing the cookie cut of the base. Still working on a final configuration, but any ideas are always welcome. ![]()

I'm hoping to have the couple bits I need to finish from Mianne in a couple of days so I can put the front on and get some plywood down. The liftgate is a little more complicated than the basic assembly, so I suspect that will slow me down a bit. I also have to get some pieces of different sized plywood just for that assembly.

gunrunnerjohn posted:Tom, I am moving the lift-gate about three feet more centered on the front straight. This will allow my next planned expansion of a yard off the side. Here's what the original plan looked like. I'm removing some of the extra legs in the middle as I want more storage under the bench. The diagonals were only there because he was using some stuff I already had. After seeing the plan, I decided to remove those so that space under there is all open.

Ok, I get it now. I have the same angles you show here (at somewhat different locations) and was just wondering what the differences were or if they had changed the arrangement. Of course your whole layout is different than mine, and bigger too, so I guess it would be somewhat different in the bracing.

If you want to make shelves using the lower cross bracing, a couple of 1" x 12"s side by side are a pretty good fit between the legs. I didn't want to mess with more plywood after getting the top on so I went the 1x12 route. Very easy and I did manage to find a few decent pieces at Home Depot. Got them screwed in place right away, before they had a chance to get all whopperjawed. Thinking I used some angle brackets on the shelves as well. I had a ton of those (one hole each end) left over from something years ago.

I did the shelving a few weeks after the initial benchwork. Tim put some extra holes in the legs for adding an additional shelf between the top and lower cross pieces so I had to order some more cross pieces and parts for those shelves.

You are looking good there with yours, coming along very nicely! I really like that shelf too, and the lift gate.

Guns,

My advise is to go slow, you have the rest of your life to work on your new layout, have fun buddy!

PCRR/Dave

Pine Creek Railroad posted:My advise is to go slow, you have the rest of your life to work on your new layout, have fun buddy!

But who knows how long that will be? I may get hit by a bus tomorrow! ![]()

![]()

Tom, I wanted under the layout to be as uncluttered as possible. First off, it'll make it easier to do the finish-up wiring (doing some pre-wiring before the plywood goes on), and it'll also facilitate having lots of storage under the layout. That being the case, I removed those braces and the extra leg and went with open space. I also tried to orient the lower braces in such a manner as to provide maximum access to the underside of the layout. Time will tell how successful I was. ![]()

GRJ, The open spaces are nice, I was actually kind of admiring that in some of the photos. You are giving me some ideas here as well! ![]() I ended up with 2' of shelves all the way around the perimeter (except for the ends which are open) below the layout with a wide open 2' 'isle' lengthwise, right down the middle. I actually ended up with pretty good access to everything from below for now. Maybe have to move a box or two if I want to get back in to something though. Of course the expansion still hasn't yet happened so it will probably all change then.

I ended up with 2' of shelves all the way around the perimeter (except for the ends which are open) below the layout with a wide open 2' 'isle' lengthwise, right down the middle. I actually ended up with pretty good access to everything from below for now. Maybe have to move a box or two if I want to get back in to something though. Of course the expansion still hasn't yet happened so it will probably all change then.

Another difference is I have concrete floors and a mechanics stool that lets me scoot around below the layout fairly easily. Just have to watch your head in certain places. A few cross braces still have traces of hair (my hair!) on them! ![]() With you having carpet the stool might be a little more difficult to maneuver down there and maybe hard on the carpet? Could still be handy to have though. They are about $20 at Harbor Freight. The rectangular one is a little lower than the round one. But the more you can do before the plywood goes down the better, that's for sure.

With you having carpet the stool might be a little more difficult to maneuver down there and maybe hard on the carpet? Could still be handy to have though. They are about $20 at Harbor Freight. The rectangular one is a little lower than the round one. But the more you can do before the plywood goes down the better, that's for sure.

Also, I added a string of 5m LEDs (600 LEDs) down the center space which helps me find things down there. I put a switch in a cross brace for the top, right where I go in with my stool for convenience. That works very well. You would probably need a couple of strings or more for the size of yours, but it's really handy to have while you are down there. That would be easier to install with the top off as well. It was an after though for me, after the layout had a top and running trains. Just another thought here, but I imagine you have probably already thought of all that.

The legs and lower cross braces are also good places to mount little things like light power, term strips, etc. Below is also a good place to hide things, keeps the skillet and rolling pin away from the old noggin...![]()

rtr12 posted:gunrunnerjohn posted:Tom, I am moving the lift-gate about three feet more centered on the front straight. This will allow my next planned expansion of a yard off the side. Here's what the original plan looked like. I'm removing some of the extra legs in the middle as I want more storage under the bench. The diagonals were only there because he was using some stuff I already had. After seeing the plan, I decided to remove those so that space under there is all open.

Ok, I get it now. I have the same angles you show here (at somewhat different locations) and was just wondering what the differences were or if they had changed the arrangement. Of course your whole layout is different than mine, and bigger too, so I guess it would be somewhat different in the bracing.

If you want to make shelves using the lower cross bracing, a couple of 1" x 12"s side by side are a pretty good fit between the legs. I didn't want to mess with more plywood after getting the top on so I went the 1x12 route. Very easy and I did manage to find a few decent pieces at Home Depot. Got them screwed in place right away, before they had a chance to get all whopperjawed. Thinking I used some angle brackets on the shelves as well. I had a ton of those (one hole each end) left over from something years ago.

I did the shelving a few weeks after the initial benchwork. Tim put some extra holes in the legs for adding an additional shelf between the top and lower cross pieces so I had to order some more cross pieces and parts for those shelves.

You are looking good there with yours, coming along very nicely! I really like that shelf too, and the lift gate.

I'm following this pretty closely!!!! I'll probably build my own bench work, but I loving seeing this develop.. Also please share any insights on the lift gate!! I'm getting a bit old to deal with a duck under...........

Woodson posted:I'm following this pretty closely!!!! I'll probably build my own bench work, but I loving seeing this develop.. Also please share any insights on the lift gate!! I'm getting a bit old to deal with a duck under...........

Think of those duck unders as a form of yoga. I'm 67 and now look forward to contorting my body under the train tables to get to a derailment on the far side of the layout, etc. My attitude about exercise and stretching is if it doesn't kill you, it's good for you.

Worse thing for me is to be too sedentary. Arnold

I can still crawl under the table, but that doesn't mean I like it. ![]() I'm also figuring that in a few years I may not be able to crawl under the table to get to the center. Besides, the control panel will be in the center, so I need it to be easy to get to. Also, I might have Woodson over to play trains, and he doesn't like ducking under the table!

I'm also figuring that in a few years I may not be able to crawl under the table to get to the center. Besides, the control panel will be in the center, so I need it to be easy to get to. Also, I might have Woodson over to play trains, and he doesn't like ducking under the table! ![]()

![]()

rtr12 posted:Also, I added a string of 5m LEDs (600 LEDs) down the center space which helps me find things down there. I put a switch in a cross brace for the top, right where I go in with my stool for convenience. That works very well. You would probably need a couple of strings or more for the size of yours, but it's really handy to have while you are down there. That would be easier to install with the top off as well. It was an after though for me, after the layout had a top and running trains. Just another thought here, but I imagine you have probably already thought of all that.The legs and lower cross braces are also good places to mount little things like light power, term strips, etc. Below is also a good place to hide things, keeps the skillet and rolling pin away from the old noggin...

I like the idea of the LED lighting, I'll have to do that. Let's see, 16 feet for each string. Four or five should light it up pretty well. FWIW, there are also high current LED's you can get in reels, I have them on my workbenches, they're great! They are really bright, and light up the bench like daylight. First picture with them on, next with them off. You can see by how dark the 'scope is above the light strip that the camera adjusted the light level down because it was so bright. ![]()

Attachments

Very nice looking John. I'm really happy to see it coming along. You will be running trains before you know it.

I think it's safe to say you have the classiest train room around.

But the look of that work shop is befitting the John we all know and admire.![]()

Good luck and have fun.

GRJ, the layout's legs may leave permanent damage to your wall to wall carpeting. Looks like you have about 32 legs that will be digging in. Your wife will have to replace the hole room if you get hit by that bus and she wants to take the layout down. Just a thought, but maybe before the layout starts getting too heavy, when you go to pick up your plywood, have them rip you two 4"x 8' strips that you can chop into 4"x 4" carpet pads. Two 8' strips will give you at least 46 carpet pads. I know you can't wait to get trains rolling and don't want to spend more time on things that will move that day farther away, but if you have a miter/chop saw and clamp down a block of wood 4" from the blade (as a stop), you can chop up those two strips in about 3 minutes.

Attachments

Dave Zucal posted:GRJ, the layout's legs may leave permanent damage to your wall to wall carpeting.

Dave -

What kind of "permanent damage" are you talking about?

Hi John, just a side question, do you use that solder iron on your bench for soldering track? I am looking for a good one to do my track!![]()

Attachments

Dave Zucal posted:GRJ, the layout's legs may leave permanent damage to your wall to wall carpeting. Looks like you have about 32 legs that will be digging in.

I've actually thought about that. I'm thinking of solutions, but I don't want big strips of wood under the legs. I was considering some of the furniture coasters to spread the load a bit.

mike g. posted:Hi John, just a side question, do you use that solder iron on your bench for soldering track? I am looking for a good one to do my track!

I actually use my old Weller 100/140W gun for heavy soldering like track, brass, etc. The Hakko is a 70W iron with temperature control, so it serves me well on the bench for wiring and PCB work.

GRJ, 4"x 4" cut from the strips you obtain from the store.

John I wouldn't do any pads under the legs, that table will be there a long time and the carpet will be replaced after the table is taken out anyway (foot traffic path). Those pads only crush a larger footprint and will get bumped every time you vacuum the floor.

CLEM brings up a good point so maybe some clear vinyl protection too. It may help keep some static sparks out of your fingers.

Attachments

John, A simple sumptin' that can be very helpful in carpeted rooms would be a 3 1/2" X 3/4" recessed puck with chair mat nipples fastened to the bottom of it.

When in place with adjustable levelers they will provide several features.

1.- carpet protection

2.- retain position of platform leg when some one kicks, taps or bumps into it.

3.- provide overall stability to the layout so it will not be jarred.

4.- When used for fingers of benchwork over carpet it is equivalent to fastening the leg to the floor. As below:

How many do you need?

Attachments

Interesting idea Tom, those look fairly simple. I just have to cut up my chair matt! ![]()

Cutting that many circles will take a bit of time, a lot easier when you have all the woodworking tools

I'll have to find my large forstner bits to make the indent for the leg. ![]()

Use a 3 1/2" hole saw to cut both the plywood and the chair mat. If you want an even soft edge you can rotate the disk on a router table with a round over bit. Use a Forstner bit the size of your adjustable foot for a 1/8" + recess. Attach the chair mat face and you are done.

Or I can drop these off to you.

Having all these tools makes it easier. I think my hole saws top out at 2". Do you do these in a drill press? How does plywood do going at all angles on a router table? I'd think it would splinter at certain angles. I don't think I've ever tried plywood with the router.

Clean router use on plywood follow the quality of the plywood. Cheap plywood with voids can yield less than nice edges. Any decent solid core plywood can router nicely. Of course always sand the finished edges with a 100 grit.

An inexpensive big box router table is OK for making disks.

I have several routers each outfitted tips I most frequently use. However, if I only could have one router my $100+/- Bosch trim router would be my choice. One hand operation, easy to use on curves and small pieces in addition to long 8' runs.

I like to round over my wire management holes and the bottom edges of all modules for safe handling.

For 3 1/2" hole saw cuts you will need a hi amp hand drill with a side handle or a drill press. I have used both, but the drill press is admittingly easier. Milwaukee hole saws last long. Drill over a back up of solid wood. Do not hit a concrete floor. Your pilot drill needs to embed it's self into a subsequent body. Sometimes it can be helpful to predrill the pilot hole.

To get the routed edges on a table I use a jig or a Phillips #2 screw driver shank and hold the disk against the bit and retard the disk from spinning too fast. Bring the bit up in stages so as to not take a big bite.

The adjustable feet are available individually at Valley Hardware in CA. Many other outlets for the feet but most others want minimum orders.

For the mat nipples I just cut them from a chair mat with the same 3 1/2" hole saw. You can buy any size mat for the amount you would need.

Nothing herein is an absolute, it's just the way I do it.

For scooting around under the benchwork this helps:

It's just a HD furniture dolly with a drop center mounted old plastic kitchen chair shell.

Attachments

Hey John, just wondering what your top-of-table height will be with the plywood installed? Not that it matters since we all have our preferred height. I assume Mianne may have two or more standard heights.

i like the led strip lighting for under the table, that's a great idea. Wish I had thought of something like that back in '98. That lighting on your bench looks great. Hard to beat the Weller 100/140 for track and heavy wire soldering.

Tom, really like your wire caddies. Nice size and easy to work with I would think. I also see you were smart and put up your backdrops BEFORE doing your benchwork! Another thing I wish I had done.

cheers, Rod

gunrunnerjohn posted:Dave Zucal posted:GRJ, the layout's legs may leave permanent damage to your wall to wall carpeting. Looks like you have about 32 legs that will be digging in.

I've actually thought about that. I'm thinking of solutions, but I don't want big strips of wood under the legs. I was considering some of the furniture coasters to spread the load a bit.

mike g. posted:Hi John, just a side question, do you use that solder iron on your bench for soldering track? I am looking for a good one to do my track!

I actually use my old Weller 100/140W gun for heavy soldering like track, brass, etc. The Hakko is a 70W iron with temperature control, so it serves me well on the bench for wiring and PCB work.

Thanks John, I have one of those wellers so it should work just fine!![]()

gunrunnerjohn posted:rtr12 posted:Also, I added a string of 5m LEDs (600 LEDs) down the center space which helps me find things down there. I put a switch in a cross brace for the top, right where I go in with my stool for convenience. That works very well. You would probably need a couple of strings or more for the size of yours, but it's really handy to have while you are down there. That would be easier to install with the top off as well. It was an after though for me, after the layout had a top and running trains. Just another thought here, but I imagine you have probably already thought of all that.The legs and lower cross braces are also good places to mount little things like light power, term strips, etc. Below is also a good place to hide things, keeps the skillet and rolling pin away from the old noggin...

I like the idea of the LED lighting, I'll have to do that. Let's see, 16 feet for each string. Four or five should light it up pretty well. FWIW, there are also high current LED's you can get in reels, I have them on my workbenches, they're great! They are really bright, and light up the bench like daylight. First picture with them on, next with them off. You can see by how dark the 'scope is above the light strip that the camera adjusted the light level down because it was so bright.

I like the workbench lighting idea. I hadn't thought of putting LEDs there? That would make a big difference in lighting and I have a shelf that would be perfect for those. I used a double, 600 LED reel of 5050s below the layout. I got two reels, but one down the middle was plenty. I will look around for the high current ones and take a look, for the work bench.

Edit (after looking around): Yikes, prices on the 600 LED strips seem to have gone WAY up since I got the ones under my layout!

How can you make more storage underneath the benchwork by removing the V-angled supports? I thought that you need them to support the table?

Just got caught up by reading this from the start. Nice looking room and benchwork John. I was wondering on the table height that you decided on too?

Tom

TrainHead posted:How can you make more storage underneath the benchwork by removing the V-angled supports? I thought that you need them to support the table?

Nope, the angle supports and the extra leg was just added by Tim because I had the parts and he was trying to use them. In the original design. lots of sections had no angle brackets. I asked Tim if I needed them, and he told me he was just using what I had. Since I also had more 4 foot sections, I went with the same design as other parts of the layout to allow maximum storage.

MNCW posted:Just got caught up by reading this from the start. Nice looking room and benchwork John. I was wondering on the table height that you decided on too?

Tom

The legs are 40" tall, by the time I add the deck and the 1" of foam I'm considering, it'll probably be around 42" to the top.

A note of caution. I had to do a lot of wiring under a layout where the owner had installed permanent shelving attached to the legs.

That made the job go extra long and was very awkward / painful I would caution against leg attached shelving. Working under the layout is hard enough.

Already having lots of shelving I mounted my shelving units on a series of furniture dollies. A regular poster here uses a series of red Harbor Freight carts to roll out when ever needed and provide full access to the underneath area.

Legs can also be a pain. I mounted knees on the wall and set the benchwork modules on top. When we moved I took the modules with me. The Mianne benchwork can be set on cantilevers the same way. Floor clear wall to wall:

Attachments

Just an FYI, I strung 100% of the buzz wiring thru the frame holes before I put my plywood top down. A whole lot easier to stand and do it than be on your back and trying to pull it thru.

For decking consider Advantech 4' X 8' X 3/4"sheets @ $30.oo +/- each. Available at 84 Lumber, select Lowe's and quality lumber yards. HD had it for a while under their brand of Ameritech.

Very strong, extremely flat and smooth. Non responsive to moisture. Certified for use in home construction to be good for four months open to weather. Very affordable.

I have been experimenting supporting it on 22" & 32" centers with no deflection in 7 years.

Also, I just added a three rail upper level to my 2 rail layout. Knowing how loud three rail trains are, as an experiment I used various deck materials. Because Advantech is so extremely dense it is the quietest structural decking material I have ever used. You can hear the difference when the train travels from any thickness plywood to Advantech. As an aside, IMO, sound systems and slower speeds make three rail wheel/track sound much more bearable.

Advantech is great stuff!

Tom, my plans include storage that is NOT connected to the layout, I've certainly already learned that lesson! I'm sure that even if I pre-wire, I'll spend lots of time down there, so I want to make sure it's as easy as possible. With the open design under the benchwork I have now, that should be pretty easy. I am planning on stringing the power wire and a few CAT5 cables around to have pre-wiring for most of the stuff. I'll still have to be down there for the interconnects, but at least it'll be a start.

John

What will you the Cat 5 for?

Bill

ogaugenut posted:What will you the Cat 5 for?

Switches, accessories, signals, lighting, etc.

I agree, John. I don’t like attached shelves either. Even after built you never know when you may need to get under there. Also, if the time comes when I can’t get under there myself, I won’t feel bad asking someone else to crawl, roll, etc into my concoction. I like the roll out storage units some folks have shown on the Forum.

I'm probably going to come up with some roll-out storage, and also in some places, just a few plastic tubs that will pull out when I need to get to them. I'm trying to orient the structure so there's maximum access from the inside and outside under the table. So far, I think I've accomplished that goal to a great degree.

This thread turned into some fantastic idea's from everyone. I'm thoroughly enjoying this, please keep the idea's coming. Only sad thing for me is i had to stop progress on my layout production until February .

Thanks John for starting this

Alex

@gunrunnerjohn, am I reading the plan correctly, basically nothing bigger than 2' x 2' squares inside legs spaced 4' x 4' ?

Alex M posted:This thread turned into some fantastic idea's from everyone. I'm thoroughly enjoying this, please keep the idea's coming. Only sad thing for me is i had to stop progress on my layout production until February .

Thanks John for starting this

Alex

John, Ditto to Alex’s comments! And I too have to wait to get to building like Alex.

Thanks guys, I'm really looking forward to completing this, even though I know it'll be a while. ![]() It's nice to actually be working on it now.

It's nice to actually be working on it now.

John D. posted:@gunrunnerjohn, am I reading the plan correctly, basically nothing bigger than 2' x 2' squares inside legs spaced 4' x 4' ?

Correct, 2x2 is the largest open space, and the legs are a maximum of 4x4 apart.

For under layout storage... a few thoughts:

Build a 1/2" plywood box the size you want with sides about 8" high

if you store cars in boxes, you can store a lot in a 2' x 3' base box (and my layout is only about 27" off the floor!)

Don't use casters or rollers.. makes the box harder to move on carpet... Instead, buy the sets of furniture moving disks at HD (multiple sets of disks are cheaper than roller or casters!) Then, drill a hole in the center and screw them into the bottom of the box in each corner....if you use a flathead screw, the plastic disk will squeeze up a but and the screw head won't snag the carpet at all! In addition, you don't lose much height, because the gliders are only about 3/4" high - much lower than a roller or caster.

They GLIDE... smoooooothly ![]()

Works great for me! (you might consider a set for an under-the-layout gliding seat too!)

... and now, back to our regularly scheduled discussion about GRJ's new layout! (Nice!)

Attachments

Good idea Eddie, I'd probably make them just shy of 2 feet across so I could put two side by side. Easy to build as well. ![]()

gunrunnerjohn posted:Having all these tools makes it easier. I think my hole saws top out at 2". Do you do these in a drill press? How does plywood do going at all angles on a router table? I'd think it would splinter at certain angles. I don't think I've ever tried plywood with the router.

You could always goto Harbor Freight and get the circular bores that fit your drill...

Eddie, I really like your sliding boxes! I have that low pile carpet too! Thank you for the great idea!! ![]()

One problem I have with hole saws is it's usually a PITA to get the wood puck out of the saw. ![]()

Plug removal from a one piece econo hole saw used with a straight thru bore approach can be a bit rough.

With the removable mandrel in a straight through pass, just unscrew the mandrel, remove it then you can poke the plug out.

My approach is to bore the hole a tad over half way from both sides, that way you have the protruding end to grab onto to for removal. This method provides a cleaner back face.

gunrunnerjohn posted:One problem I have with hole saws is it's usually a PITA to get the wood puck out of the saw.

That's what the 2 small holes by the center are for. Punching out the wood plug.

I know what the holes are for, but it's still a PITA, especially if you're doing a bunch of them. I suppose another approach is to use the bandsaw and a pivot and just cut a circle that way.

Eddie I really like the sliding box idea too. I imagine they would slide equally well on a painted concrete floor also. A side benefit is that you also get some protection in the event of a basement flood due to a plumbing leak or a leaky hot water heater. This is a big worry of mine because the house is plumbed with poly b pipe. Yikes! 😱 If it's overland water flood though, all bets are off!

Rod

There BETTER NOT be any floods in my basement! ![]()

Hello John, I have been watching your progress on the new layout. I believe it will be a premiere layout when you finish it. I would not worry about the carpet unless you are moving. I love this set of wheels you fabricated, you are a talented Macgyver sir. here is the proof.

BTW that is a nice townhouse. ![]()

All I have to do is find a suitable seat.

Ahh, cutting circles. You can cut sub road bed circles with a circular saw and smaller circles on a table saw.

If you encounter dexterity difficulty while cutting curved road bed with the circular saw there are even dished blades available for circular cutting with a circular saw.

Table saw small circle cutting is done with a table mounted pivot. It blew me away when an elderly deaf mute master carpenter showed me how to do this. He could not speak but was one of my best instructors.

I agree with John, The pair of top holes or even the diagonal side slots are a pain to use because you are applying uneven pressure and the plug, especially if thick, will jam. Just remove the mandrel. A vise helps. Also cutting half way from each side will give you a pull out handle.

The frequent point of difficulty with a hole saw is cost. You only want a sharp hole saw and the cost can be an issue. Plus, an assortment of them for on site use can get heavy & stolen. I have several dozen for wood and tile, Extremely helpful.

Yep, I don't want to have more money tied up in tools than I do in trains! ![]()

![]()

Check out arcusblade.com web site for saw circle cutting blades. Phone 502-495-2954. Blades start at $44. They also have trammels to mount your circular saw.

One of the uses suggested on their website is specifically for cutting curved model train track beds.

gunrunnerjohn posted:Yep, I don't want to have more money tied up in tools than I do in trains!

John, if you are like most of the rest of us train nuts, that would be hard to do! 😱

Rod

Rod Stewart posted:gunrunnerjohn posted:Yep, I don't want to have more money tied up in tools than I do in trains!

John, if you are like most of the rest of us train nuts, that would be hard to do! 😱

Rod

Yep, probably no danger in that happening if the truth were to be told. ![]()

Attachments

Tom, I like the rolling wire spool racks. Where did you score them?

And those cantilevered knees off your walls - excellent!

David

David98 posted:Tom, I like the rolling wire spool racks. Where did you score them?

Tom,

$30 to hold 8 rolls! I think I am going to order one! Better than the homemade thing I made! Thank you!

Only $20 on Amazon search for Gardner-Bender-WSP-100E-Electrical-Dispenser

Tom, thanks!

David

David98 posted:Only $20 on Amazon search for Gardner-Bender-WSP-100E-Electrical-Dispenser

Tom, thanks!

David

Thank you David! My adult kids finally convinced me to join Amazon Prime. It has been great Christmas shopping since I hate stores. I’ll look it up tomorrow!!!

Thanks for the tip, picked up a wire dispenser on Amazon for $20.06 total with tax and free shipping.

John a really cool way to cut plywood into sub roadbed curves, Is take your plywood (don't go cheap with plywood) to a place that makes counter tops. They can cut that plywood into curves on their CNC machine. I have not done this but my neighbor offered to do it.

Jim McGehee posted:Thanks for the tip, picked up a wire dispenser on Amazon for $20.06 total with tax and free shipping.

I'm going to be right behind you, Jim! ![]()

Tom Tee posted:For decking consider Advantech 4' X 8' X 3/4"sheets @ $30.oo +/- each. Available at 84 Lumber, select Lowe's and quality lumber yards. HD had it for a while under their brand of Ameritech.

Very strong, extremely flat and smooth. Non responsive to moisture. Certified for use in home construction to be good for four months open to weather. Very affordable.

I have been experimenting supporting it on 22" & 32" centers with no deflection in 7 years.

Also, I just added a three rail upper level to my 2 rail layout. Knowing how loud three rail trains are, as an experiment I used various deck materials. Because Advantech is so extremely dense it is the quietest structural decking material I have ever used. You can hear the difference when the train travels from any thickness plywood to Advantech. As an aside, IMO, sound systems and slower speeds make three rail wheel/track sound much more bearable.

Advantech is great stuff!

That Advantech is an awesome product! We used it to floor a 25x21 loft we put in one of our buildings. It is printed with markings for attaching at 16, 19.2, and 24 inches. Now the weather rating is no warping or separation issues for 500 days in weather. Bad thing is it will kill circle saw blades and nails spark when you shoot em its so hard! But that is a good thing also!

Jim