For those old-timers like me, you may recall that in the early days of this forum discussions of voltage spikes were quite common. This was probably due to the fact that our trains were being made with more and more electronic features. I don't read much about voltage spikes anymore, and am not sure why that is.

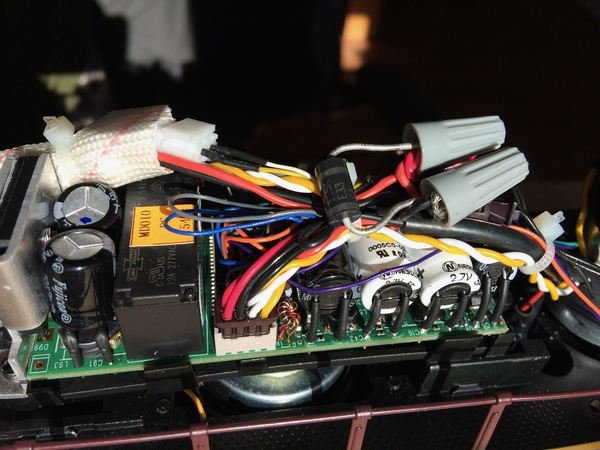

I recently had a collision on my layout resulting in some derailments. One of the engines involved developed a problem and wouldn't run. Fortunately, it was under warranty and was repaired. This got me thinking about voltage spikes. FWIW: I can't be sure it was the collision that caused the damage, but it seems logical.

I recall reading in the early DCS days that the TIU contained voltage spike protection - but that the circuit would eventually lose its efficacy over time. Am not sure if my memory is accurate for either one of the above statements. I am running both DCS and Legacy and thus all power is routed through my TIU's and my TIU's are quite old.

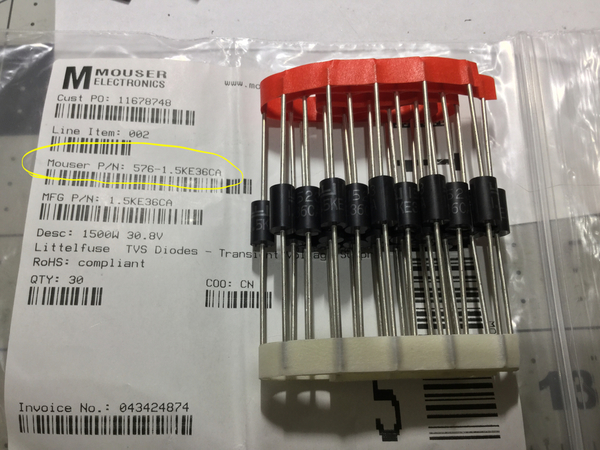

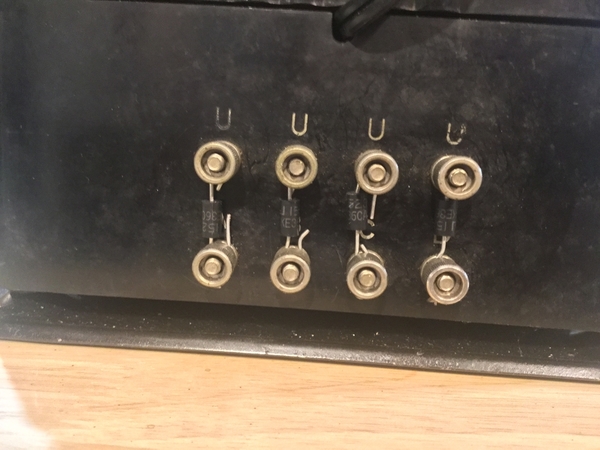

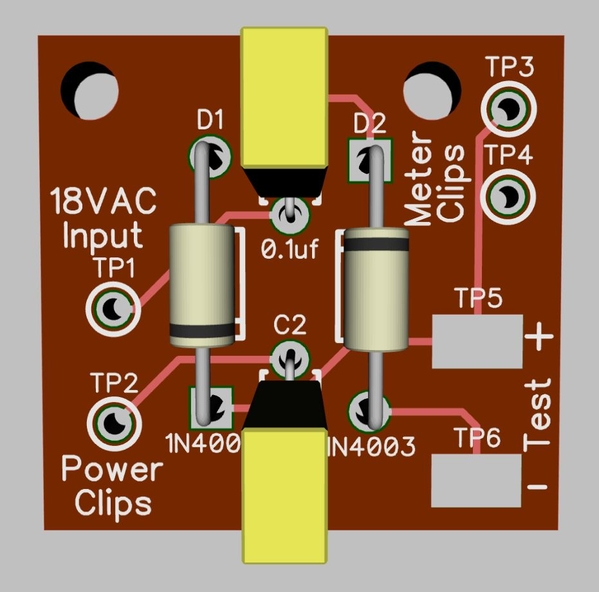

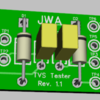

I remembered having something from those early days and dug around my workshop and found a little bag of Mouser ESD suppressors ~ part #625-1 5KE33CA - these are transient voltage spike suppressor diodes. Then, I remembered making a voltage suppressor using these diodes on my last layout - its really easy, just bend the ends 90 degress and insert in banana plugs of transformer.

Long story short, I made four of them for Z-4000 transformer outlets as a stop-gap measure until I learn more.

Has anyone kept up on voltage spikes and whether this is still a problem? Am not sure if more recent trains are more robust electronically speaking then the ones from the late 90s and early 2000's?