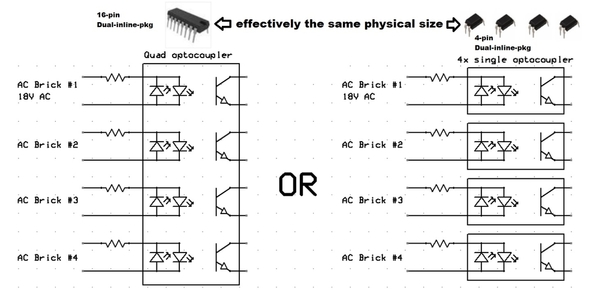

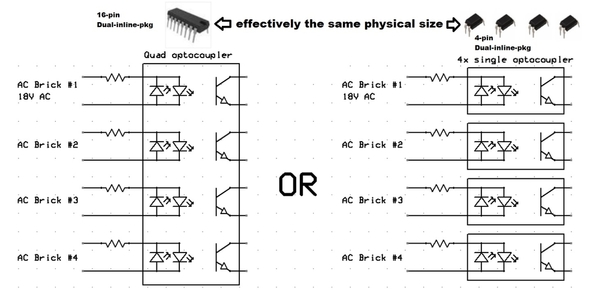

Just about any AC-input optocoupler will work. I just checked on eBay and for about $1 (free shipping from Asia), you can get 5 single-channel PS2505-1 optocouplers. You'd use 4 of them. Note that these devices come in 1, 2, and 4 channel packages and can be "stacked" so that 4 1-channel devices looks like 1 4-channel if that makes sense.

The PS2505-1, PS2505-2, and PS2505-4 are shown above from DigiKey though minimum shipping from DigiKey is over $4 these days.

As I type this out, I now recall and dug up a previous discussion about AC-input optocouplers:

https://ogrforum.ogaugerr.com/...89#69285198810032689

So I see there I recommended if only going to "stock" one optocoupler type in your DIY parts stash, use the AC-input LTV-8141. This part would work too. And it too comes in 1, 2, and 4 channel versions though their numbering scheme is LTV-8141, LTV-8241, and LTV-8441 respectively.

--------------

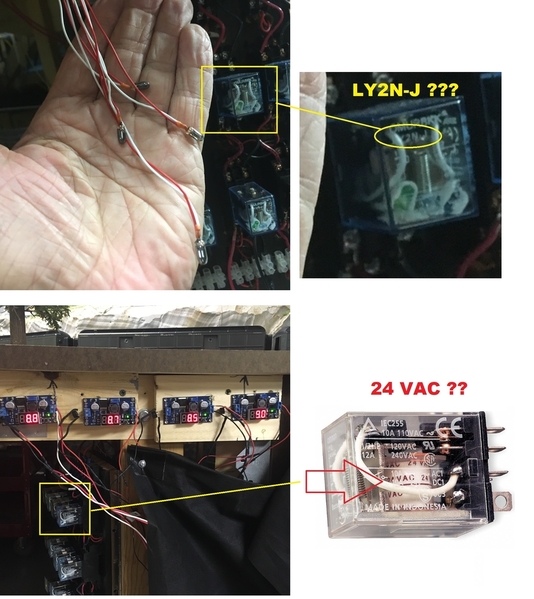

But as I stated earlier, you have to be a determined DIY'er. Some comments that may help or confuse depending on your comfort zone. I measured the input trigger current to the 4-channel relay module. Each trigger measured about 1 mA with 12V applied. So it takes 4 mA to trigger all 4 relays.

Each optocoupler is essentially acting as a bridge rectifier to convert AC to DC. Drive each optocoupler at, say, 10 mA. In other words an input resistor of 1K-5K. You need a capacitor to smooth the full-wave rectified output otherwise the relays might chatter/buzz at the line frequency. Something like 1uF - 10uF should work.

If someone/anyone is actually contemplating wiring one up I can peel additional layers of the onion; it may bring tears to your eyes  .

.

![]()