To cut the chase a bit, the quietest layout I've seen as an adult has astro-turf with super snap track on it. (12x15? Three loop ovals.)

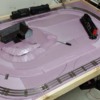

Mine is all wood scrap- 4.5" x 9', 2x4 frame, various runners with emphasis on the corners, and center. Done without much planning, as fast as I could, and to the best of my injured ability. 0-27,O,& Super O.

A single sheet of homemade 7/16 plywood with flexible laminate glue, and DAP contact cement mix my stepfather whipped up, and "country boy" pressed in the garage, with various items, including the Lincoln.

I ran it bare, then with the foam on it, then glued.

Glue made it louder in the mid-range. No glue the center track, seemed to produce more lows. Overall less "booming" was better for me.

I'm pretty content with the outcome, but know now....

If I still could, I'd experiment with sandwiched felt, cork, thin carpet or carpet pad, or similar. And/or for roadbed support.

I used a tube of foam safe adhesive (Locktite if I remember right).

Foam safe was suggested to me on another forum (rather expensive compared to the "other tube products").

Others claim Liquid Nail, or even caulk would have been "good enough".

I think it was Lowe's foam, but there is a HD right there too, so???

I don't think it matters much either, but in theory, softer foam should be quieter.

I choose what I thought would handle abuse better, I had to be able to climb & lean on it. The grass matt rebounds, so you don't see any dents

The foam I bought had a clear protective skin on one side.(vapor? Hey... I think it was embossed Lowe's)

I didn't notice until after it was glued down, and it peeled off some scrap being tossed .

.

Almost three years, and the big sheets aren't shifted, or lifted. Nor do I think it will be an issue. I would peel it  .

.

On one piece, the barrier was "up". But the larger pieces went embossed side down.

The "one", would have likely become an issue had I been laying ground cover directly vs a grass mat.

After finishing a flat layout. I eventually played with the scrap a few months ago, and had a ball.

It really is just so hard to mess up when carving foam. I can't push for trying it out hard enough.

If I hadn't taught the dogs not to dig, and scratch, they could have carved it for me.

The next layout will ideally also have thicker foam & terrain reliefs carved down into it by hot wire.

With the barrier removed, there is no "right side". It all takes paint the same.

There is no "soak" to speak of, so a little paint can go a long way, if you spread it around fast enough .

.

I didn't bother with screws to the foam/frame, except as posts to hold it still from side movement while it's glue cured.

It's not dense enough for threads to grab well, the head/washer would have to be huge.

Also, pressing with a large flat surface will help with it being "Water Level".

Pressing with separate objects allows flex over the glue, and it will have high and low spots. Though barely visible, future measuring from the ground may be affected.

I didn't have the speed (dry time) or physical reach then, to use an adhesive spreader which would have helped level it too.

Attaching things....

Most items do have screws, but not all reach to the wood. Some are just pushed into the foam like a thumb tack, to stop the item from shifting..

Some things just have nails, or even cotter pins as "stakes"

I've thought about going to nylon screws too, since the holes are there in the wood now.

A lot of sound travels through the metal screws.

Some foam scenery sits in place on screw heads, sticking up about 1/2" above the wood & foam, to act as location dowels for holes on the foam scenery's underside.

Homasote is quieter. Maybe as quiet as the astroturf, (but I doubt it).

My age at the time, and the fact it was long ago, make me question my own opinion, but my Grandfather used it, or a similar knock off.

It dried out after a number of years, and released a dust out of the holes in the edges, that my Grandmother vetoed against, soon after it began."I like the noise better" she said..

His old basement layout had its Homasote layer stripped off before it saw track.

It was twice as expensive when I found it too.

That's why I didn't choose the sound board either. For the price, it didn't seem as stable, and with the constant vibration I feared dust. Nasty, fiberglass-like dust . I hate insulation type fibers in me.

. I hate insulation type fibers in me.

I intend to play with felt, rubber, and rubbery roadbed things on it when I get down to the basement. Foam? Oh yes there will still be some foam

By next summer I hope to start something on top of the bench work again.