Well, after tearing down the old layout and finally deciding on a track plan I was satisfied with, the new layout construction has begun. I started on Halloween night and here's where I'm at so far.

The layout is constructed with 2 x 4's because that is what I had from my old layout, and it will be covered with 3/4" plywood, also from the old layout. It is L-Girder with pre-drilled holes for the wiring. I'm still deciding what to do with the walls, since this room was never designed to be the train room I have a lot of work ahead of me, but that's what is fun about this hobby.

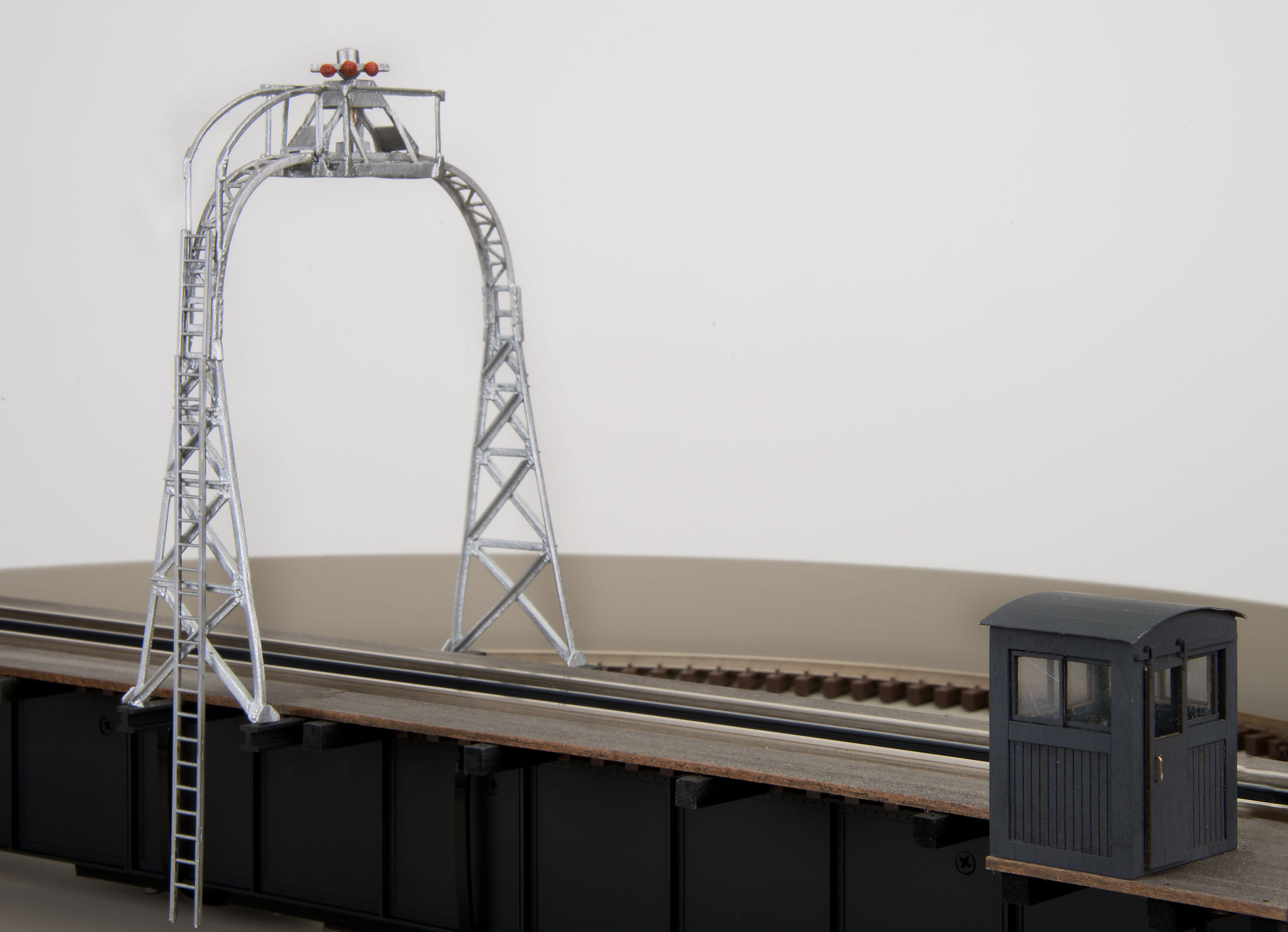

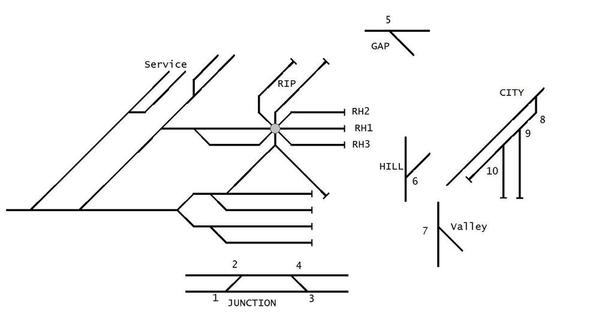

As for a track plan, I am using a hybrid of some plans that members Ace and Stewart designed for me using SCARM. I am going to be using Gargraves track with Ross Custom switches, minimum 0-72 on the mainline, down to 0-63 around the roundhouse, and one smaller track with 0-54, but this track will be raised and include the city.

I know how much I enjoy seeing other peoples layouts in progress so I will do my best to keep the post updated with photos that hopefully will either assist, help or inspire others with their layouts. I'm excited about the possibility of having the trains at least running by Christmas for the boys (All three of them)

Darren