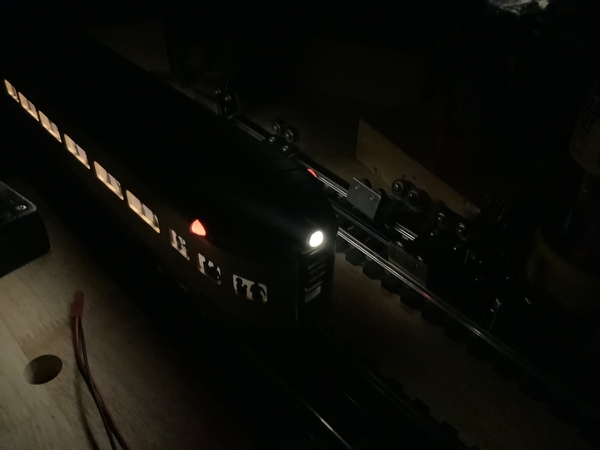

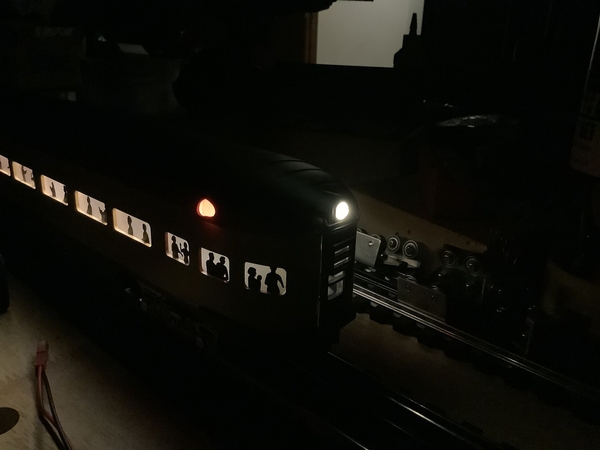

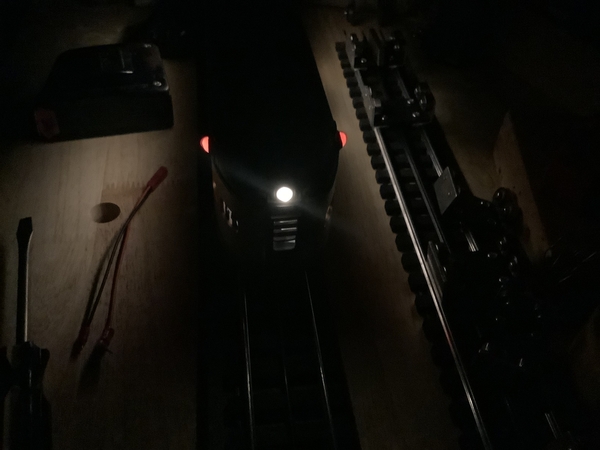

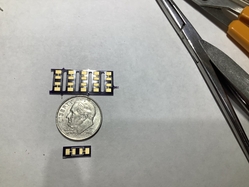

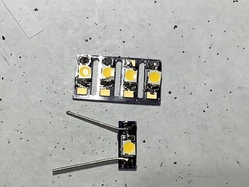

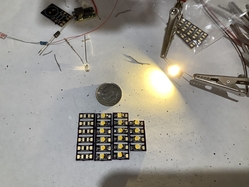

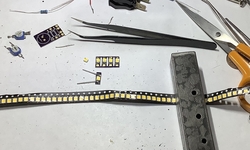

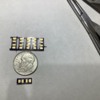

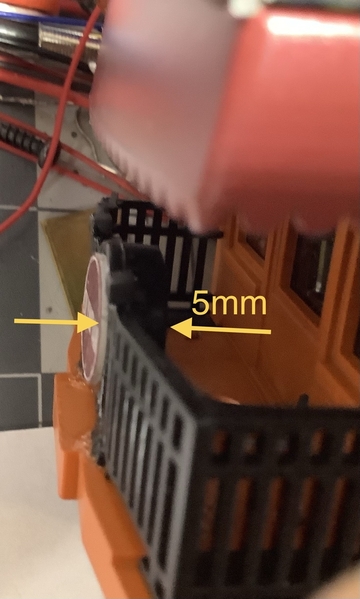

I've been working diligently on updating my 4 Santa Fe passenger cars (people and LED lighting). I'm on my last one, the 6-19179 observation car. I am following the suggestions from this thread pretty closely. My tail lights are very similar (but not exactly) to those posted by @stan2004, but I'm using, basically, the lighting method suggested by @gunrunnerjohn. I'm planning on using CA to glue 3mm warm white leds to the lenses, but the lenses are so thick. If you reference the picture at the end I've put in blue lines where I think I'll cut off the excess plastic from the lenses. There will still be a nib on the lens to hold it in place. My thinking is that the bulbs will be closer to the where the light is seen, also it makes it a bit easier to work with, especially with the clear lens.

My question is, has anyone done this? My only concern is that when I cut off the ends of the lenses, the new ends will not be smooth. Does this cause significant problems on how the light passes through the lens?