Carl,

I understand the differences quite well, thank you!  I may have erred in my description of what I was trying to use as an example as a true "passing siding". I probably should have called it a layout with a common circle within an oval or something like that. My geometry/math skills are pretty decent.

I may have erred in my description of what I was trying to use as an example as a true "passing siding". I probably should have called it a layout with a common circle within an oval or something like that. My geometry/math skills are pretty decent.

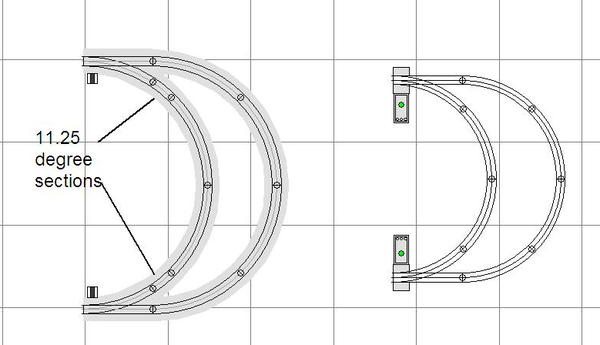

My examples were relating specifically to O72, so O60 is not the "only" orphan. I am well aware there are no turnouts for O84 and O96, I assumed it would be understood I was talking about a same diameter (named) curve and turnout. I'll admit it's possible O36 or O48 turnouts do not suffer from this problem, as I do not have experience with those. (edit: now that I played with it in RR Track, I see O36 is not the same situation(no short fitters with removed ballast), but does require you to add a 11.25 degree curve to each turnout to make it a "drop in" for a curve since the turnout is only 33.75 degrees, instead of the 45 degrees of an O36 curve)

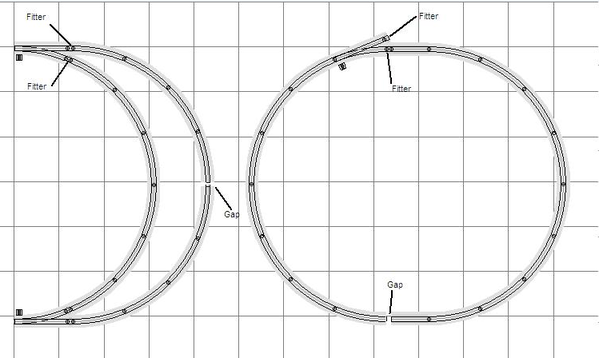

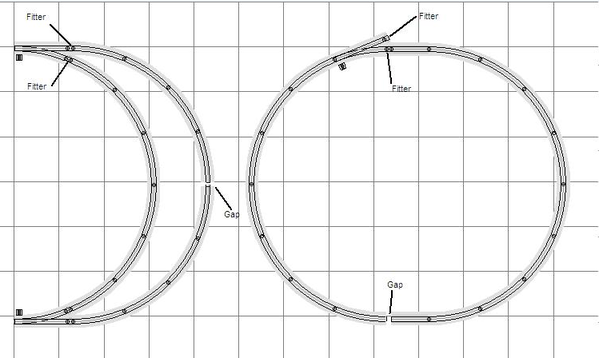

Here are some RR Track sketches. Note the gaps in the FasTrack for trying to make either the "circle within an oval" layout, or the gap caused by "dropping in" an O72 turnout in place of a curve. This is due to the little fitter pieces required on the end of the turnout, if you don't modify the track you want to connect to the turnout. The gap is approximately an inch. These are standard O72 curves and turnouts(with a single 10" straight on each side in the rightmost picture), with the fitter pieces to go with the turnouts. I didn't bother to show the left half of the oval so we could focus on the area of interest here(the same gap would exist there for the left drawing).

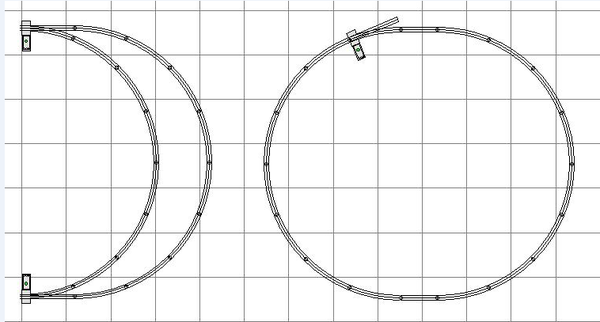

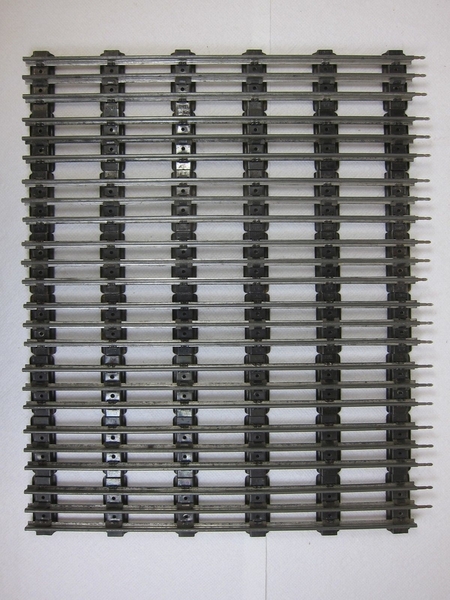

The following pic shows the same track arrangement for traditional tubular. Standard O72 curves and turnouts, again with a single 10" straight in the right hand pic (obviously no fitters). There is no overlap, nor any gaps.

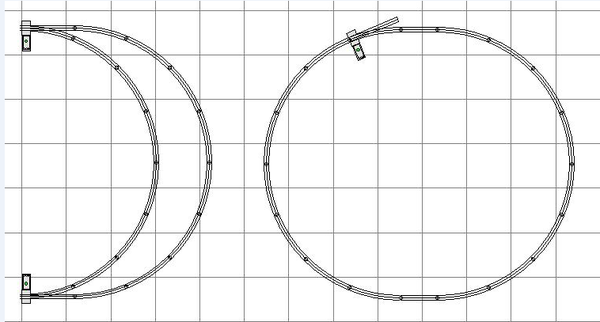

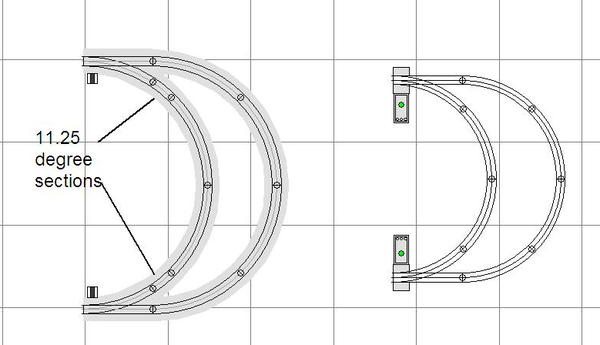

This last sketch is comparing O36 FasTrack to O31 tubular. So the O36 is not as bad a situation as the O72, but you do need to add either the (2) 11.25 degree sections (or a half O36, since a regular O36 is 45 degrees). If one is just building this simple example, the single half curve would be fine(one less track joint), but if you wanted to expand on it, the (2) 11.25 degree sections might be a better option, as otherwise the track joints would be at different angles than the outer part of the track.

To your last point, while I didn't explicitly state it, yes, that is supposedly the whole issue to be aware of. Traditional Lionel O Tubular was based on "nominal circle of X diameter", while FasTrack was designed to instead result in a certain spacing between parallel lines once you go through the turnout.

-Dave