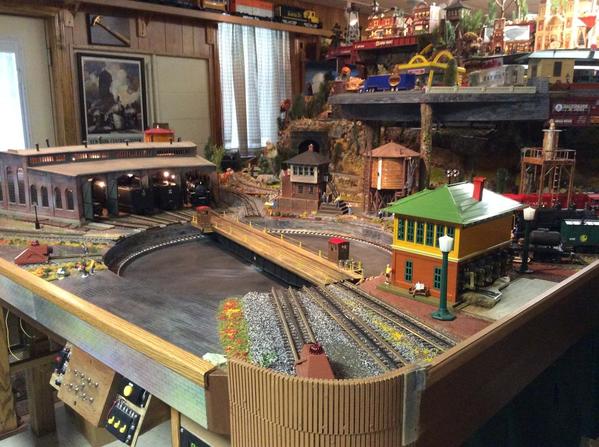

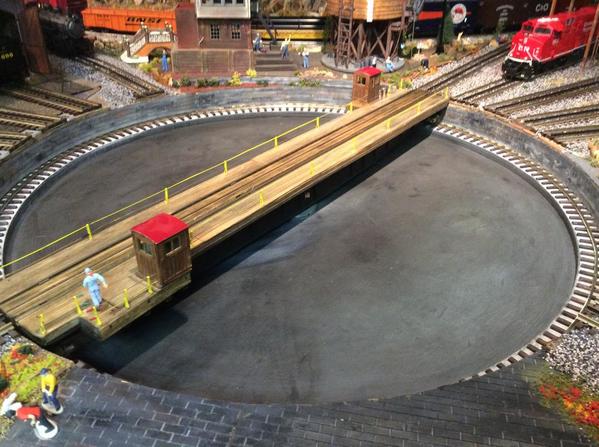

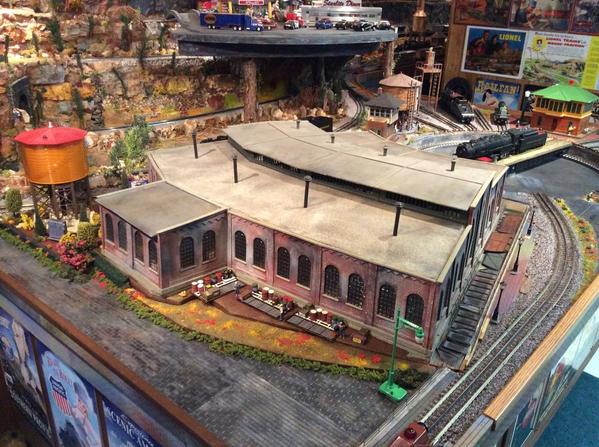

A material list for a turntable I built several years ago.

Turntable project slideshow. Have fun with your project . Click on the underlined phrase to link.

. Click on the underlined phrase to link.

Parts list.

Parts List from Diamond Scale. Diamond Scale is under new ownership since I bought my parts in May 2007. MK-111 turntable drive kit (1)

DT-09 turntable dolly trucks, (1) pair (not available) Dolly trucks were fabricated.

CB-30 turntable control cab (1) may not be required if using the Bowser 7902 bridge detail kit.

Bowser turntable parts and detail kits are no longer available.

AK-104 Turntable Arch Kit Angled (1) (not available).

WG-9 Worm and Drive Gear (Boston Gear 1049G) 7/16" bore. (1)required.

WS-87 3/16" X 6" Worm gear shaft (1)required.

B-187 3/16" ID Bronze Bushings (2) required.

SC-187 3/16" ID Shaft Collar (2) required.

B-437 7/16" ID Bronze Bushings (2) required

SC-437 7/16" ID Shaft Collar (2) required.

US-1 3/16" X 1/8" universal drive. (1)

Bowser Trains

#7902 O Gauge Bridge detail kit.

#79417 handrail post. An Additional (20) were required.

Bowser Turntables and detail part kits are no longer available.

Kaplar Lumber.

KP1186-OP24 Scale 10" X 12" .208" X .250" match up to Atlas railroad ties.

KP1126-OP24 Scale 2" X 10" .042" X .208" addition deck material

Plastruct.

#90423 ABS Ladder

Evergreen Scale Models.

#146 .040" x .125" Styrene Strips.

#9077 .015" Clear Styrene sheet

#9040 .040" White Styrene sheet

K&S Engineering.

#91066 1/8" brass angle X .022" X 36"

#92098 3/16" brass bar X 12"

Crow River Products.

#O-56 Scale Electric Winch Kit. (2) required

Atlas.

#6056 40" flex track curved pit rail.

#6058 40" rigid track Bridge rails

#6094 Track Screws.

MSC Industrial Supply/ J&L Industrial Supply.

#607Z Bearing 7 X 19 X 6 mm bearing. (4) required.

Micro Fasteners.

RMB0212 2-56 X 3/4" brass round head screws.

Krylon paint.

#2323 River Rock spray paint

#1602 Ultra Flat Black spray paint

MinWax stain.

#224 Special Walnut. deck stain

Sherwin Williams primer/sealer.

#141-1699 Preprite ProBlock Alkyd Primer/Sealer in spray cans.

Floquil/Polyscale acrylic paint.

#F414137 Grimy Black

#F414329 Railroad Tie Brown

#F404076 Coach Green

Aluminum Ring and bridge sides were fabricated at a local fab shop 1/4" Aluminum sheet.

7/16" drive shaft and "T" bar were fabricated locally.

4' X 8' MDO board local lumber supply.

Premium grade frame lumber local lumber supply.

Miscellaneous hardware and framing screws local supply/hardware.

Construction adhesive local supply.

Wire and connectors, from my truck.