I bought an engine on a hunch. It appeared that it may have been converted to 3 rail? I checked and all the wheels have one side isolated electrically. The tender seems to be opposite of the engine. There seems to be three rail pickups added on by someone to just the tender? Unless, that's how they did it at the factory? I'm hoping for an easy convert back to 2 rail!

Replies sorted oldest to newest

Sounds like a trivial conversion. I did that to a Lobaugh Berk for a very short article in OGR many years ago - 15 minutes each way.

It sounds like you are right, it was a simple 3 rail conversion. If the flanges are 2 rail size, and all wheels insulated on one side, it should be a real easy convert back to 2 rail. I think it is easier to wire up for 2-rail than 3 rail. You don't need the extra pickups and such.

I'm sure hoping for that! I just tested the motor and it worked fine. There's a lot of damage from shipping to different parts on the engine. The front pilot is smashed a bit with the coupler pushed up and in. The rear of the tender has a corner bent and some other stuff. I bought it as is, damaged.

It seems like the front pilot is missing something. I thought it was bent as the rear wheels of the front pilot don't touch the track. It seems more like some type of spacer is missing to lower the whole assembly downward. The mounting screw is quite long. I think I'll be monkeying around with this one for a hobby!

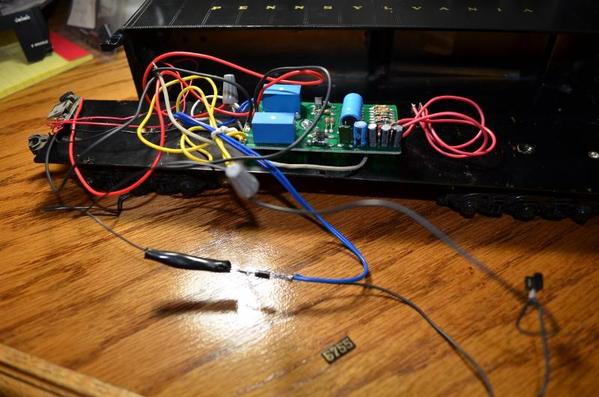

I opened up the tender and was surprised at some type of large control board inside. I think it looks like it has some capabilities that I hadn't expected. No sound though. Some type of switch on the tender bottom that I haven't established it's purpose for? There's another small regulator board just for the rear markers that has a diode (to make it work in one direction only?). Maybe this came from the factory this way after all?? They are two rail flanges though?

That looks like someone modified a 2 rail Weaver M1a for stud contact running. You didn't happen to purchase it from my friend Hugo in France? He is a PRR modeler and dabbled in stud contact O scale for several years before going all the way to 2 rail. The Samhongsa built Weaver M1a's were a little light on detail but are good runners.

Ed Rappe

I got it in a Trainz auction. Looks decent to me. I don't know the history of these, or the PRR for that matter! Just thought it would be an easy job. I'll probably add command control and sound with DCS.

I can't find anything that old on the Weaver site before '04. The listing said it was built in the 90's? Seems well built and hopefully a good runner like you say. Just going to need some mods.

I'm actually wondering if that tender switch is for reverse! ???

It was listed as three rail and I never thought about stud rail. I have never seen stud rail for that matter!

Joe, did you follow this thread here recently?

https://ogrforum.ogaugerr.com/t...ebay-2-rail-listings

Ship that engine back to Trainz for selling damaged goods or shipping it carelessly.

Having looked at several 2-rail engines as 3RS candidates, the conversion to 3-rail isn't really difficult, even on a steam locomotive. Basically, the third rail pickup is tied to the motor positive and the right-hand rail pickup (on the locomotive as I recall) is tied to common. All you have to do is disconnect the 3-rail pickup and re-connect the right-hand rail pickup back to motor positive. Or if you want to be fancy and have an engine that goes both ways, put in a DPDT switch as illustrated below (this will probably get me shunned on this forum now):

By the way, this was what I'm thinking about doing with some DC Atlas Trainman 2-rail engines if they are offered in road names I want.

Attachments

I'm sorry for the confusion. I bought it as a damaged engine!

Looks like Mike CT has one shown on the 3rs post.

I found a number board inside the gear box that I'm not sure where it belongs? Maybe on the tender? The pilot is so smashed maybe it went down low on there? Here's a pic of the tender's board with a single pole switch for some purpose? The number board is in front of it all.

Attachments

Whatever the issues are, here's hoping for a speedy "recovery"; you can't beat an M1 for brute strength and good looks...

Mark in Oregon

Thanks to all so far! I had just bought a three rail version of the 3rd Rail M1. I ran it around the tree at Christmas. I didn't want another. The price was right and it looked like it was two rail already.

It appears that the fireman's side is isolated for anyone else doing this. Maybe double check anyways. The tender was probably reversed to help with any ground issues? I'll have to put it back or isolate the tender from the engine.

I don't see any sign of how the power was picked up from these wheels originally? No signs of wiper marks or anywhere they were mounted? Looks like I'll have to get creative again and make something... or get some tender trucks with wipers.

Most 2-rail engines pick up on one side from the engine, and the other side from the tender. A wire plug, or wireless drawbar is used to transfer the connection from the tender to the motor in the engine. Also if a plug, often transfers the connection from the engine to the tender for backup lights or markers.

With all those drivers and tender wheels, you should not need wipers on either the loco or the tender.

I don't know about this vintage Weaver, but on a lot of older stuff, the tneder was one polarity, and the engine was the other, so that the drawbar had to be insulated.

By the way, there is a guy at Weaver named "Gary" who does their repair work. He might remember the models and be able to answer some questions for you.

Thanks Jim, that would answer why I don't see any pickup markings. The tender drawbar pin is riveted to the tender frame. The drawbar itself, looks like it's also connected to the engine's frame? I'll have to check with a meter. Unless maybe, that got swapped out? It looks factory.

On a number of newer engines, the trucks are insulated from the tender body, so the drawbar does not have to be. In either case, though, you should find one side of the polarity on the tender, and one on the engine. Just install a 2 wire plug and you can run straight DC. 1 wire for the track power and one wire for the light power back to the tender.

Thanks Jim, that would answer why I don't see any pickup markings. The tender drawbar pin is riveted to the tender frame. The drawbar itself, looks like it's also connected to the engine's frame? I'll have to check with a meter. Unless maybe, that got swapped out? It looks factory.

This might be a situation where the tender and the locomotive are isolated on the same side. In that case, the drawbar wouldn't need to be insulated. I could see some logic in doing it this way as you can make a stronger drawbar mounting since you don't have to insulate it. This thread is making me wish I had bid higher on a 2-rail Weaver CNW Yellow Jacket that went up on eBay about a year ago.

Whoa, not my day today!

Looks like I'm wrong again. The drawbar looked stock from the bottom. Inside the engine, someone replaced the mounting nut and washer. The drawbar's mounting screw goes thru a frame T type plastic washer, and was probably isolated at one time.

By swapping out the washer by the modifier, the drawbar was grounding to the engine's frame and the tender on a meter. I bet it didn't as it came from the factory. Looks like all I need is an isolating washer and reverse the tender trucks for a third time!

Looks are deceiving! Thanks again Jim and Matt.

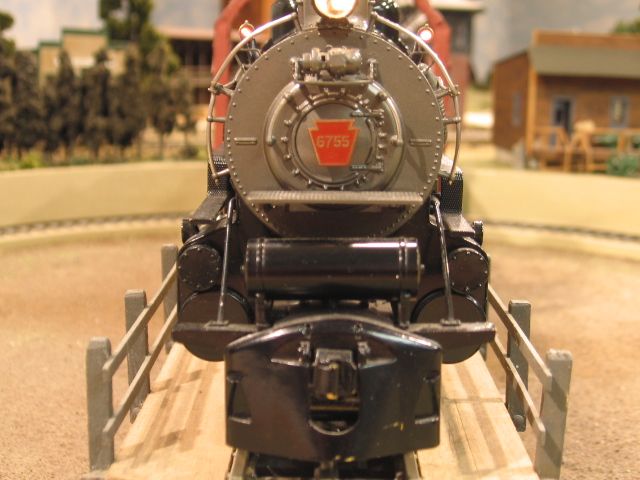

A few more pictures. This model has been upgraded to EOB speed control, The white walls have been removed from the drivers.

Just get a piece of bakelite and make a new drawbar. Then use miniature connectors to bring power from the tender to the motor and headlight. Much simpler than those isolated drawbars that carry current, and much, much more reliable. If you need the backup light, another wire is necessary. I'd skip it at first, while you test this thing. Good luck! I bet your frame is bent ahead of the front drivers - and I bet you can fix it easily.

No, don't. Some very talented folks made it look almost like 2- rail, then discovered that it was way easier to just go 2- rail. Way easier, and way cheaper. If you like three rail, it simply has to be because you like the looks of three rail track.

The front coupler was a fold down type, may be you could model it that way. Also that front pilot/cow catcher is extended for the three rail flanges, it needs adjusted back to at least look more proto-typical. Here's what the real one looks like.

One of my projects that never seems to get done. It always looked a bit lacking in detail, even though its a brass model. I believe it has been discussed that it was Weaver's first Samhogsa, brass model. I spent a hour at the Railroad Museum of Pennsylvania, Lancaster, PA, taking photos of the real one, with the intent of adding detail. Most needed detail appears to be air, brake, and water lines. Most noted would be completion of the piping on the two air pumps. Then a repaint of the oxide red roof/tender areas, and final application of a dull coat. Any way here is a link to my picture file on the 1:1 6755 M1b Click to access. The differences between an M1a and M1b are minor. Some say the solid pilot with fold down coupler and the accessible boiler clean out plugs (3/6) visible just ahead of the cab were the only differences. It does appear that the ?? top water pre heater manifold??, just behind the smoke stack, may have been installed 180 degrees out on the model. I have seen some HO models that had a little more air line detail around the sand dome.

PSC seems to have some nice detail part specific for this model.

Have fun with your project.![]() Mike

Mike![]()

I had hoped to get a picture of a decent back-head detail. Not to be had.

This is kind-of a sign of lack of respect.

Wow Mike, those are great pics in your album. I don't know what I should about steamers. I would have to do more research to use your pics correctly so I know what exactly I'm seeing. Thank u for sharing those!!

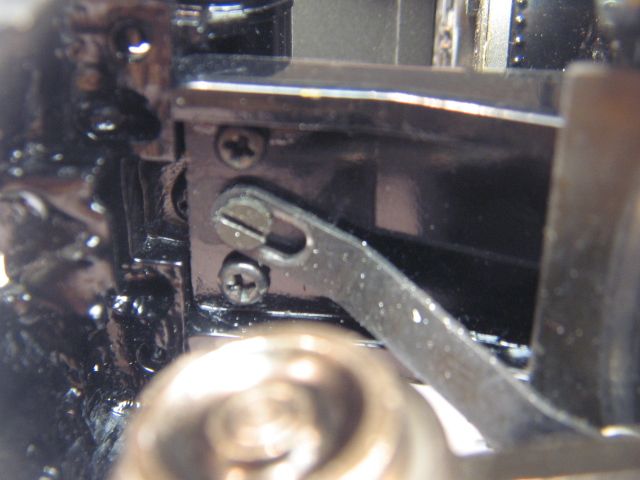

If U could look, is there a spacer of some type under the screw of the front pilot connecting to the frame? I put washers there and they work for now.

Attachments

Here are pictures of the front pilot mounting.

Mike, thank you again! That last pic shows a spacer that I'm missing.

The M1 is a handsome locomotive - my personal preference goes to the early versions with eight axle tenders. I believe the boiler contour is more graceful on about half of the early locomotives, and I never really liked the later cylinder saddle. But they are all handsome. - mine is an M1a with six axle tender from USH. That neat book by Tom Harley is essential for this model.

I agree with you about the "early versions"; I personally feel that most of Pennsy's steamers looked much better in their pre-war attire; the post-war mods just don't do it for me...(not as much,anyway).

Mark in Oregon