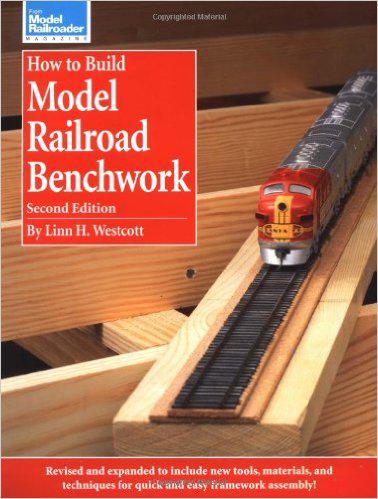

I have seen two different ways of the building the bench work and laying track. They are as follows:

1.) Lay plywood flat over framing and then rest elevated supports with track on top of Plywood over table top.

2.) Attach elevated track supports directly framing, and attach track bed to supports

I am wondering which way is the better way to go between the two, especially when track noise is to be considered. Which way did you build yours and why?

Thanks,

Joe