I had been working on the layout the last few days & after cleaning up In thought I would run some trains. Woops; missed a tool on the tracks & as my MTH Imperial (PS3) came around the corner off it went to the floor. Approximately 55" down. What a mess. I don't know whether it would be cheaper to send it back to MTH for repairs or just try & find another one to buy new.

Replies sorted oldest to newest

A lot of damage there, I don't know that MTH is going to repair it, they'd probably replace the shell. It may be cheaper to sell this for parts and find another one. The tender looks like it could be fixed, but there's a lot of work ahead for that locomotive!

OH how heartbreaking!!!! I am SO sorry.

Don't know the answer $$wise, but I would try and fix it if it were mine....

I am heartbroken. I love that engine. I'm into smoke & boy did that thing smoke.

Sorry to see this, Spence.

But I have to tell you: 'WHOOPS" is NOT the word I would have used.

Fred

Oh no!!

Spence,

I do not know the answer to your question. I just want to commiserate with you on your accident with such a fine locomotive! It is very sad!

Spence - That is too bad. Why do things like that always happen to our favorite engines?

Art

Fred; LOL' I needed that. You made me laugh.

I am heartbroken. I love that engine. I'm into smoke & boy did that thing smoke.

silly question here, do the electronics still function, does it still move?

Penn-P. Nothing works. It's not even recognized now.

Ouch. You have my sympathies, because I know your pain all too well, Spence. I left a razor saw on the layout about a year ago and my Legacy ATSF 3751 launched itself off the layout and fell 42 inches to the floor. It was never the same again.

Spence I feel your pain And I agree with Fred. And I would of been so upset that my neighbors would of heard me.

Ouch. It can be replaced. Now might be a high priced point in the cycle of trains purchases, but you already know that. Keep an eye out with Trainz. they seem to have these come up often.

My stomach sank when I read this, so I can't imagine how you feel. ![]()

Hi Spence,

So sorry this happened to you, If there's anyway i can help just let me know.

Alex

Ohmigod; awful mess! ![]()

Been there, done that, but not with an engine as nice as that.

That shell may be repairable, but I don't know how successful that cab roof will be to bend back. Being cast, it may just crack. Worth a shot though. What have you got to lose?

Besides cosmetic damage you may also have a bent axle or two from a fall like that.

I would disassemble and check everything carefully before making the call to repair or replace.

As was said, you can likely replace the boiler casting with a new one.

Let us know how it goes.

Rod

Spence my friend....I am so sorry to hear this.![]() Glad you posted because this is a good reminder for all of us to check the track. I can't tell you the number of times I almost forgot to pick something up off of the track before I ran the trains...I have been lucky so far...

Glad you posted because this is a good reminder for all of us to check the track. I can't tell you the number of times I almost forgot to pick something up off of the track before I ran the trains...I have been lucky so far...

Hope you are able to fix or replace it....

Alan

Sorry for your loss, Spence. when a favorite train bites the dust it is almost like losing a family member. Sounds like selling it for parts is your best course.......hope you find a replacement soon!

-Pete

I ran into my cat she was sleeping in my tunnel on my old layout with my vision line challenger.. It didnt even derail ...I guess i am lucky .. Cat was unhurt to..

So sorry Spence. As Roseanne Roseanna-Danna used to say, "It's always somethin".

Penn-P. Nothing works. It's not even recognized now.

Ouch, that hurts, I guess its time for a replacement then......I'll bet the motor's still good though. I think Gun runners suggestion is probably the best option, parting it out and using the $$ towards another one.

Alex; it doesn't look like anything can be done to save this. This came out in about March of 2013. It's going to be hard to find a replacement.

I am heartbroken. I love that engine. I'm into smoke & boy did that thing smoke.

Heartbreaking indeed, Spence. I feel for you, so sad. I'm certain the event generated substantial amounts of blue smoke as well.

Instantly felt sick when I saw this, but Spence you can be honest with us. your big boy destroyed right as the new Lionel big boy is coming out? I'm on to you.

Turn this into a dummy engine after selling off some parts maybe? Can you imagine a DOUBLE HEADED BIG BOY CONSIST!?!?!

That hurts, In the wallet too. I feel for you. Maybe you could convince UP to work on it. Then again They cant even repair or run their own steam.

Oh, Man! I feel really bad for your loss, especially since I am still looking for a Railking PS3 Big Boy. Ironically that's exactly how I lost my favorite subway train of all time: the R-1. I was finished working on a tunnel and I left my small screwdriver on the tracks and once it hit that curve the power car and second car hit the floor, hard. Unfortunately, I was not able to find another set and had to sell the remaining non-powered cars, so I feel your pain. Again my sympathies and I hope you can find a replacement. *cough* Premier Big Boy

But I have to tell you: 'WHOOPS" is NOT the word I would have used.

Agreed.

OUCH. I feel so bad for you, Spence.

But I have to tell you: 'WHOOPS" is NOT the word I would have used.

Agreed.

I don't think he could of written the words he used.

I had the same thoughts. Why not model 4005's wreck on your layout?

So sorry to hear this.....ouch!

Peter

oooohhhh. That's an awful accident there Spence. The shell can be repaired with a little heat, paint and patience, but I'll bet Midge has one and a tender shell on the shelf. The drawbar probably popped the connector joint on the engine, and those are readily available for sure. It looks worse than it is... bet the boards are still good. I'd send it in to MTH as a Christmas surprise and get a firsthand assessment. Keep us posted, and sorry about your luck my friend. I've had bad accidents too.

Anything can be fixed. Having said that...that was a big fall, certainly.

The fact that it won't respond may be "simply" loose boards; open the tender

up and press everything back together.

If you have bent driver axles...maybe try to find another one and keep this one (or

sell this one) for parts. The cab roof can actually be cut off (the damaged part)

and repaired...if you have a little scratch building experience.

Tough. Not a new thought, but this is why my layout has plexiglas shields (3 - 4")

along every edge that is not along the wall.

You could always pay through the nose for one of the new scale (MTH or Lionel) Big Boys to "punish" yourself for being careless. Oh, the pain! (Uh-huh.)

That stinks! I haven't had an engine fall since I was in my early teens (knock on wood). After my first engine fell, I instituted a new rule. After doing any trackwork or layout work, run an engine that is easy to replace or has less value to you (this is much harder now that i'm in O scale).

I think you could make that big boy shell into a cool scene on the layout and sell the internal to help recover costs of a new one?

Nutz. I sold a favorite N&W Y6b (RK) and the new owner destroyed it just a few days after receiving it. I felt real sorry for him. It was a great engine. If it were mine, I'd try to salvage the electronics and part-out the reset.

My thought is, with the newer fancier Big Boys coming out, there may be a fire-sale on the older models in the next year or so.

Gilly

That is terrible, Spence. I really feel bad for you.

.....

Dennis

That's painful to look at.

Gandy

Spence, I like the rest of the folks that have posted about your loss, am sorry as well.

I sent this post on to our Club members, told them to open it and look at your loss. Our Club has a 24x36 traveling "O" Gauge layout, and I've mentioned several times of this same thing is going to happen to us. We double head Allegheney's pulling lots of coal loads, and at times add a pusher behind this, and we have a minimal amount of protection if one does start off the track. Normally they short out, and comes to a halt, but one of these times, we're going to draw a short straw, and it's going to stop at floor level, like yours did. I appreciate you sharing this with the crowd, as it's good food for thought for any of us!

We also have a hinged walk through bridge on one end, we raise to get into the inner circle, and it's come close, being left up at times, trains start running, and luckily, one of us has caught it, before the floor did! Thanks again Spence....Brandy ![]()

Like it was said the good news is there are new ones coming out...

But being an engineer I cannot have stuff sitting around broken, so I would either order the parts or look on the bay for one that can be used as such and repair it... but that is just in my nature.

Nothing ventured, nothing gained. Its worth doing a thorough examination of damage, check out parts availability. I joined the I left the ___on the tracks club, even renewed my subscription. Both of my incidents were viewed as a slow motion catastrophe. I was stunned like a deer in the headlights...a lot of cussing and self loathing for an extended period. Spence, theres nothing to lose in taking a good look at it once the scar's healed.

Oh Spence -

I cringed when I read the title, my stomach hurt as I read the post.

Let us know if you want some help finding a replacement. Between all of us I bet we can find you one.

Best thing I can say about that video was the Doo Wop was nice ![]()

Take care Spence,

Paul

Sorry Spence. I hope you will find another one. What an expense.

I am surprised that tears weren't running down this thread. What a bummer. ![]()

Hope you find a replacement soon.

So sorry for your loss Spence. What a terrible thing to have happen. It looks extremely difficult to repair at best. If only the tool would have shorted the track first, before the de-railment. As others have said, I would have used much more colorful language than Woops had that happened to me.

I almost did the same thing with a diesel a few weeks ago, left some roadway I was fiddling with on a curve and just barely got the engine stopped as it was de-railing when it hit the roadway. Luckily it was going very slowly when it happened and stopped just short of the layout's edge. It did come close enough to make the old ticker speed up considerably. I have been thinking about doing something like banjoflyer has done around the preimeter. I am now thinking more strongly about it.

My LHS had some RK Imperial Big Boy's a while back. They may have sold them all, but could possibly have something left? I am going there tomorrow if you would like me to look, I will be happy to check if you are interested. What was the MTH part number for your engine?

I've run into stuff on the tracks before, but I've been fortunate that none of the wrecks ended up on the floor! I've dropped a few freight cars, some survived, some didn't, but only minor losses. I've never had an event like this, and it sure is a sad day for Spencer RR Lines! Makes me want to send a $150 locomotive around first to clear the tracks! ![]()

OH boy I can only dream about owning one but to have and to loose it that way............so sorry

James

MAN!!GREAT SCOTT!!!I am sorry to see this has happened to you.MTH might replace it if its under warrenty.Guys here can disagree with me here.But this is the very reason my layout is pretty closse to the floor.With the money these locomotives cost.I am not taking that chance.You might want to see if there is a mth repairmen closse to you.And take it to him just to get his openion.But from the looks from it.Maybe you should just get another one.It will take time to get over this.I know if it was me I to would be upset.I hope things work out for the better for you.

Well, guess real world history repeats itself in the model world - tools left on the tracks are a recipe for a train wreck, but...

**** GOD ALMIGHTY that was painful to look at, Spencer. ![]()

I guess this is a reason I stayed with floor layouts running all my expensive stuff - a nice soft carpet seems to protect any big wrecks.

Regardless, I really hope there will be a silver lining to this big storm cloud over one of your favorite engines....somewhere. ![]()

I must admit, I was already going to add to the sides of my layout where that one curve got really close to the edge, but now I'm not going to run trains there without being ready to catch any locomotive going over the side, until I get that portion added right at that spot. It's not that I wasn't already gonna do it, but Spencer's experience has lit a fire under me to make it happen faster than ever. My new plan is to make it happen probably on Sunday if I can.

Just so sad I learned this lesson over at such a cost to anyone.

**** GOD ALMIGHTY that was painful to look at, Spencer. ![]()

Darn right. ![]()

Spencer, you gotta keep us all posted as to what you're gonna do here.

Hi Spence ,

it may be possible to fix the roof with a little heat froma propane torch , heated very slowly and then some pliers on the roof slowly straightening it a little at the time as you keep the bent area heated , do not over do the heat .

Like was mentioned check for loose boards ,once the boards are checked it is most likely the driver axle or driver is bent , out of quarter causing it to bind , then take drive rods loose or the cab off and turn over by hand to see if axles are bent or any of the drivers are cracked , if all that is good , it could be repaired .

Cosmetic for sure , a bent axle is more of a job , but Joe at Baldwin Forge could fix the drive line I am sure .

Bernie

I feel your pain Spence. ![]() Why is it that those things always happen to your favorite and not the old clunker you've had for years? How many additional things did you break from the tantrum you threw after the crash?

Why is it that those things always happen to your favorite and not the old clunker you've had for years? How many additional things did you break from the tantrum you threw after the crash?

Well I've been working on this all afternoon & guess what. I got the thing running (short video attached). The engine is just sitting on the rear trucks. Believe it or not I found the spring that goes on them along with the small washer but what I need is the small clip that holds the washer on. There's a groove in the pin that this clip fits into & locks everything in place. Can anyone help me?

Attachments

Well I've been working on this all afternoon & guess what. I got the thing running (short video attached). The engine is just sitting on the rear trucks. Believe it or not I found the spring that goes on them along with the small washer but what I need is the small clip that holds the washer on. There's a groove in the pin that this clip fits into & locks everything in place. Can anyone help me?

Spence,

Try a hardware store or auto parts store, you need a e-clip or a horseshoe clip.

Art

That's great news, glad things are looking up for you. Maybe now the rest can be repaired as well.

That's great news Spence! The internals are OK and it's just a cosmetic issue at this point!

Art; thank you, I couldn't think of the name of those clips. (Old age LOL).

Penn P; LOL;

Volphin: I can live with the external damage.

Well I've been working on this all afternoon & guess what. I got the thing running (short video attached).

U N B E L I E V A B L E ! ! !

Spence...your guardian angel is trying hard to make it up to you for that 55" fall.

The fact that the engine runs at all is hard to fathom.

Run out right now and buy a Lottery Ticket before your luck runs out!

Great News!

Mark

Spence - I'm speechless![]() , but if it makes you feel any better, I had a Lionel B&A scale Hudson hit the floor. I'm glad you got yours running. I wish you the best.

, but if it makes you feel any better, I had a Lionel B&A scale Hudson hit the floor. I'm glad you got yours running. I wish you the best.

Time heals most wounds, I think it will all work out. Good Luck!

It will be perfect.

Wow, got it running and made a mock-up of what an MTH Railking Imperial depleting coal load would look like.

Great news. Next step.................

Sounds like a good way to protect your collection when running on your layout. It also helps when visitors come and try to touch a moving train. Where to buy the plexiglaas sheet? What is the best way to cut the material?

Can you provide some pictures of your installation.

could you make another roof for it, say from brass? Glad you got your treasure running again!

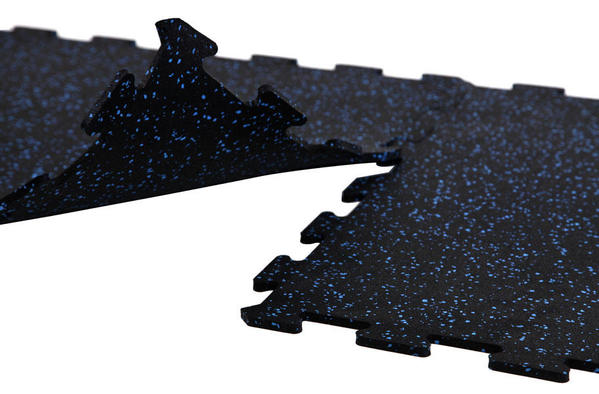

What a relief. My heart hurt reading down this thread. I can assure you that some good will come out of your misfortune as I now plan on doing the Plexiglas edge guard as previously mentioned on here along with my plan for the locking rubber floor tiles.

Spence: I'm sorry to hear about what happened. I just checked all my spare parts, and unfortunately, I don't have anything. Could a piece of silicone or neoprene tubing hold it in place?

Hang in there.

It will be perfect.

I was thinking the same!

Spence,

First I would like to say how sorry I feel for you right now. Sometimes s#@t happens. It really painful because an little oversite of your own doing caused so much pain.

How much is the deductable on your home owners insurance? Do you have a rider for your trains?

Good luck with which ever hoice you make.

Jim

Banjoflyer: LOL, very funny.

NJCJoe: LOL

Laidoffsick;LOL

You guys made me laugh. I needed that after today's fiasco.

Guess I should have read ALL the post before i commented. Glad to see that she is up and running. A little more TLC in the roof and tender and you'll be back in business. ![]()

Heart breaking to say the least. Since I am finally getting into the building of my layout I am seeing where there are some needs to be addressed to stop something like this happening in the furture. Perhaps I crazy, but I have purchased most of the engines, Big Boy, Challenger in brass, 844, 9000 class UP, a Texas, 3751, 2-6-6-6, a Cab forward and several lesser steamers, and special passengers cars and 50 or 60 cars before laying one set of rails. I love just looking at them, they remind me of my childhood around the San Bernardino and Colton yards. I stopped buying guns once I was hit by the bug, can't do both, especially at the young age of 75.

Spence, I came late to your thread, but I'm sure glad to see that you have this valuable engine running. Best wishes with whatever further you wish to do with it.

It's a pre Thanksgiving Miracle - Never thought I'd see that video today ![]()

Good karma to you Spence.

Paul

Hey Spence, it's about that time of year, so why not ask ole Santa for a 4x8 sheet of 3/16 Lexan to cut some strips out of. That's what I'm proposing we do to the Club "O" Gauge, as it will also take care of those little fingers that pass by when it's running, during one of our "Open to the Public" runs. That stuff is bullitt proof, not that we'll shoot at the trains, just a form of speech!

Glad to see that you got it running again. Now u can do the body work-n-paint, or do a heavy weathering job, or both.

Once again I'm glad that you shared your delima, as I bet it's made everyone who has read this post, think twice, and do a double take towards their layout, or both.

................................................................................Brandy![]()

![]()

The cab roof? Looks like the biggest problem is the bent cab roof? I've never seen one of these locos in person so don't know if it's possible to straighten out that bend? Is the shell diecast? Anyone have any experience with it? The coal load could be repaired by gluing in some crushed real coal with dilute white glue so I wouldn't worry about that. If the cab roof can be fixed , new coal , and a bit of weathering and the loco should look better than new.It's a great sign that the loco runs well after the fall so nothing inside was shaken loose. ...DaveB

Try a hardware store or auto parts store, you need a e-clip or a horseshoe clip.

That's a "C clip".

If you need a chunk of real coal to break up to refill your tender, email me and I think I can send you some.

It is unfortunate but sometimes bad things happen to all of us at times. Depending on your level of manual dexterity just about anything can be fixed. The cab can be restored by first removing it, tapping the bend carefully into place cleaning/roughing up the area with 180 grit wet dry paper and using automobile body putty to remold the damaged area. It then must be cut to the original lines of the cab with a special file called a "cheese grater" , sanded smooth, primed painted, and re-lettered if necessary. Probably easier just to "bite the bullet" and buy a new cab. Call MTH service, explain the problem and they may offer a solution.

If all else fails there are engine cab restorers like Len Carparelli that can make that cab look new again. Here's Lens website www.lencarparelli.com

SPENCE

GLAD YOU GOT IT RUNNING. LET ME KNOW IF YOU NEED SOME BLACK DIAMONDS FOR THE TENDER

STEVE

Sorry for your loss and hope you can do something to turn this "God of Iron" into a survivor. I have lost cars to the floor and were able to recover them with some adjustments or just minor loss of detail like a latch on a Rail King boxcar door broken off. This might help us to build some passive scenery or other barriers around switches or curves with floor exposure where derailment action is more likely to occur with adverse consequences.

Try a hardware store or auto parts store, you need a e-clip or a horseshoe clip.

That's a "C clip".

It is actually an E-Clip. You can see the difference here and it's easy to tell why they call it an E-Clip.

Here's a C-Clip

Here's an E-Clip

Attachments

Try a hardware store or auto parts store, you need a e-clip or a horseshoe clip.

That's a "C clip".

It is actually an E-Clip. You can see the difference here and it's easy to tell why they call it an E-Clip.

Here's a C-Clip

Here's an E-Clip

Right John, the c-clip is actually an inside snap ring.

Art

John,

Thank you for the correction!

Spence,

So glad you got her running. I've never repaired a bent cab roof, but do know that when some folks try to bend theirs back it ends up breaking. Don't know if it needs to be heated first, but you may want to research the process before diving in.

Hi Spence,

That's great you got her running, now time for some bodywork ![]()

Alex

I straightened out a bent roof on a 2025 steamer a few years ago. The trick was to apply pressure to the roof to straighten out the bend. It took me about a week. Die cast zinc will slowly cold flow if a constant pressure is placed on it. Just take it easy.

I have straightened out 711 switches which are also die cast zinc.

You can get any kind of clip you need from McMaster Carr.

Spence, If you take the shell off, the roof of the cab may be a separate part. I know on Premier models it is. So MTH maybe able to help if they have that part.

I have worked with MTH on engines that were dropped, and they can even repaint some touchup work if necessary. The question is cost versus value. But it the roof is a separate detail part, it would be worth calling to see if they have it. G

Congratulations on getting it running!

Gilly

I thought about putting down those rubber tiles in my aisles to help protect falling objects. I thought to myself, why would I need to invest in these, I'll be careful. So I just epoxied my concrete floor.

After reading this thread, I do believe I will invest in those rubber tiles after all. They may not prevent all damage, but they will lessen it.

Sorry for your pain Spence, but be assured we have all learned something from this.

Ron

Attachments

You can get any kind of clip you need from McMaster Carr.

Thank you everyone for your kind, funny, & helpful remarks. This is a great forum to be on.

I have 2 questions; is there some place where I can get a schematic of this engine or does anyone know the size of the clip I will need?

I don't own a set of calipers to measure the width of the pin.

Thank you everyone for your kind, funny, & helpful remarks. This is a great forum to be on.

I have 2 questions; is there some place where I can get a schematic of this engine or does anyone know the size of the clip I will need?

I don't own a set of calipers to measure the width of the pin.

Take the truck with the pin with you to the hardware store, and pick out a pin that will fit.

glad to see it lives. I had same engine but sold it.

seems the wick always getting burned and smoke dropped off hopefully you have better luck.

the bent roof on engine is repairable with slight heating of roof and careful manipulation can be accomplished.

I like you have had a few engines drop 4 feet to floor but my own fault!

had a raised bridge and no micro switches to cut power to tracks after the 3rd time of repairing an engine the micro switches were installed. and to this day I will run a train in each direction with bridge up to verify the track power is off so engines stop 2 feet away from repairman's gulch!

have a great train day and enjoy the imperial big boy the sounds are incredible!

Bob; the pin is on the engine itself not the trucks. I really don't want to bring the engine because I have everything dry fitted on it plus it weighs a ton.

Spence;

I was shocked and saddened by the damage, but glad to hear you got it running.

I never tried to reshape something like that roof without breaking it off, good luck.

Have you contacted MTH about the clip? If not in stock they should be able to tell you the size you need. Regarding advise on the Premier roof being a applied part (assuming yours is an Imperial RK unit), perhaps one of the Premier parts will fit.

Time to consider how I'll avoid such an instance on my new layout.

Bob; the pin is on the engine itself not the trucks. I really don't want to bring the engine because I have everything dry fitted on it plus it weighs a ton.

You should be able to "guestimate" the size of the pin. Buy a couple that may fit. They are pretty cheap, and you can return the ones that don't work. Most Service-Star HW stores have a good selection of small hardware like this. If not, an autoparts store should also have some. If you have a Harborfreight store will have a multipack of various sizes.

Russell & Bob; I intend to call MTH service dept. when they open at noon & hopefully get the info I need.

Very nice. I wish I had that yesterday. (LOL)

Had to check in on this thread.

It runs! It doesn't wobble. It can be fixed.

Nothing new to add; pleased to see it run - and run well.

Heating the cab roof is a method that can work - I've did it once years ago on a

friend's PW steamer. But it's case by case. Try it. What are you going to do - mess

it up? Hopefully the RK does have a separate cab.

Coal load repair: small gravel sprayed flat black.

Got some e-clips at Ace Hardware last week.

Once it's presentable, weather it, dirty it up (washes; Bragdon's powders) - it's not like

"COND: EX" is an issue any more. Have some fun with it.

====

Plus, Mr Wolf - your loco seems to have been well made. Yup.

Spence - Please don't take this as anything other than an attempt at humor and not trying to make light of your misfortune.

Remember Joe Btfsplk from Little Abner? I have a friend that is always having really bad luck and the only positive is the stories that are generated. The other day he was mulching leaves with his riding mower and put it in the garage while it was still hot. He went out in the back yard to have a cigar and his wife hollered at his that the garage was on fire. The mulched leaves caught on fire and nearly burned his house down. Major damage to the garage and his car.

Art

Attachments

As others have said, ouch, I feel your pain.

Worst case, you will have to spring for a new one. ![]() Place the dead one either on far away siding with good side showing, or else put it "on the scrapyard ground" with workman working on it as in scrapping it.

Place the dead one either on far away siding with good side showing, or else put it "on the scrapyard ground" with workman working on it as in scrapping it.![]()

Art; LOL

Spence I am glad you are able to repair the engine. I wasn't so lucky with one of mine.

Doug

You can buy a meter and a dial caliper from Harbor Freight for less than $10 each. I bought a couple of meters 2 years ago for $2 each.

As others have said, ouch, I feel your pain.

Worst case, you will have to spring for a new one. ![]() Place the dead one either on far away siding with good side showing, or else put it "on the scrapyard ground" with workman working on it as in scrapping it.

Place the dead one either on far away siding with good side showing, or else put it "on the scrapyard ground" with workman working on it as in scrapping it.![]()

Appears it's running! Just in need of some repairs.

After reading this thread, I do believe I will invest in those rubber tiles after all. They may not prevent all damage, but they will lessen it.

I got some of these, the 'cheapie' versions from Harbor Freight (yours look much nicer). Then dropped my DCS remote and missed the mats by a only mere two feet or so. However, they are quite comfortable for my little fat feet to stand on. I still think they are a good idea though.

Reminds me of the time I rammed my HO 4449 into the cat, busted the drive axle lose, so glad it still works. Fortunately my life like docksider was the floor jumper, where is one of those in O gauge when you need one. I was thinking something about Montgomery Scott from the Enterprise level of talent may have been needed, till I saw it lives!

Reminds me of the time I rammed my HO 4449 into the cat, busted the drive axle lose, so glad it still works. Fortunately my life like docksider was the floor jumper, where is one of those in O gauge when you need one. I was thinking something about Montgomery Scott from the Enterprise level of talent may have been needed, till I saw it lives!

Well . . . what about the cat?

Reminds me of the time I rammed my HO 4449 into the cat, busted the drive axle lose, so glad it still works. Fortunately my life like docksider was the floor jumper, where is one of those in O gauge when you need one. I was thinking something about Montgomery Scott from the Enterprise level of talent may have been needed, till I saw it lives!

Well . . . what about the cat?

She stared at me with a look of, and your point. She was unharmed and lived many many years.

I have straightened out 711 switches which are also die cast zinc.

I don't want to hijack the thread, and I'm not sure of protocol, here, but I do want to find out more about how you did this. Can we start a new thread concerning straightening 711 switches (and die cast zinc in general), or is it ok to continue the discussion here? E.g., what tools and techniques did you use, how long does it take, how to you measure progress, etc.?

Thanks.

Steven J. Serenska

Straightening bent die cast is an interesting topic that should be a new post because of its interest to many on this forum.

Here is a post I started about straightening die cast:

Here is a post I started about straightening die cast:

Thanks for link. Just added ModelTrainForum to my list of forums!!![]()