I recently purchased an MTH Z-4000 transformer. I have tested all the ports with a voltage meter to ensure that I am receiving the correct voltage and found no issues. I have separately connected the two main loops to the layout to the right and left throttle ports of the Z-4000 respectively. when I power-up the transformer, both the left and right voltage meters return a voltage number. When I engage only one throttle, both trains power-up and commence moving as opposed to the one train assigned to that throttle. Any explanation as to why I can't seem to engage the two track loops separately?

Replies sorted oldest to newest

This is 100% external and your track wiring simply has connected the 2 outputs. Because the transformer is in phase (it's one transformer) the outputs don't short out and the meter just shows the voltage that actually is there.

This isn't the first time someone made this mistake.

This issue could either be caused by hot wires connecting both loops together or possibly the track if the loops are connected together through an unisolated crossover.

Thank you for your responses, I do have two crossover track sections on the two large loops that I am powering with the Z-4000. The crossovers are designed to switch the outer train to the inner loop and visa versa however; the crossover track sections are not being powered currently and their wires have been removed. Is there anything else I should be looking for?

If you want want to have the loops be electrically isolated then there needs to be a gap of some sort to prevent center rail electrical connection through the crossovers. If using tubular track, this is done with fibre pins at the switch end between loops. If using FasTrack, then an isolation piece is typically used between switches. Another option would be to cut a gap in the center rail.

Ok, I have tested the Z-4000 by setting-up two straight tracks to test the accuracy of the voltage and amps. The throttles work fine and only train at time powers up when its respective throttle is thrown. I have cut the center rail in each of the crossover sections between their respective switches to eliminate power between the loops. I checked the terminal blocks and connections for the two loops and they appear correct. The problem appears to stem from the outer loop "A". As soon as I connect the leads from the terminal block to the transformer my problems begin. When I power up the "A" loop, the amps increase quickly and the red light begins to flash, which I understand to mean there is an overload of amps. The "B" loop seems to work fine but again, both voltage meters are increasing in volts. When I disconnect the leads for the "A" loop the "B" loop works fine however, voltage is still being registered on the voltage meter for the "A" loop. What's more telling is the fact that prior to getting Z-4000, I was using a Lionel ZW to power both the "A" and "B" loops and had no issues. Between the time I was using the Lionel ZW and the acquisition of the Z-4000 no alterations to the wiring had occurred.

I even tried bypassing the terminal block for "A" loop connections altogether by simply running wires from the transformer directly to the track and I all that happened was that the amperage shot up and the red warning on the transformer glowed red.

I am at my wit's end with this right now and was hoping to have this problem remedied prior to my grand daughter coming over on Easter to see the layout. Needless to say this is most disappointing.

@Butchie posted:Ok, I have tested the Z-4000 by setting-up two straight tracks to test the accuracy of the voltage and amps. The throttles work fine and only train at time powers up when its respective throttle is thrown. I have cut the center rail in each of the crossover sections between their respective switches to eliminate power between the loops. I checked the terminal blocks and connections for the two loops and they appear correct. The problem appears to stem from the outer loop "A". As soon as I connect the leads from the terminal block to the transformer my problems begin. When I power up the "A" loop, the amps increase quickly and the red light begins to flash, which I understand to mean there is an overload of amps. The "B" loop seems to work fine but again, both voltage meters are increasing in volts. When I disconnect the leads for the "A" loop the "B" loop works fine however, voltage is still being registered on the voltage meter for the "A" loop. What's more telling is the fact that prior to getting Z-4000, I was using a Lionel ZW to power both the "A" and "B" loops and had no issues. Between the time I was using the Lionel ZW and the acquisition of the Z-4000 no alterations to the wiring had occurred.

I even tried bypassing the terminal block for "A" loop connections altogether by simply running wires from the transformer directly to the track and I all that happened was that the amperage shot up and the red warning on the transformer glowed red.

I am at my wit's end with this right now and was hoping to have this problem remedied prior to my grand daughter coming over on Easter to see the layout. Needless to say this is most disappointing.

That would seem to eliminate the Z-4000 as the source of the problem.

Is anything else connected to the transformer throttle outputs besides the terminal blocks ?

Do you use a separate terminal block for each throttle and that terminal block only serves one loop ?

Is it possible you have a feed from one terminal block connecting to the wrong loop ?

Do the terminal blocks only supply track power - no accessories ?

What happens if you by-pass the terminal block that feeds outer loop "A" and just connect the throttle output that feeds that terminal block directly to the outer loop ?

Sounds to me there is a connection between the loops and possibly a short between the inner and outer rails. I would take a voltmeter and do a resistance check at various points looking for a short and for continuity between the center rails of the loops. I realize you said there were no changes in the layout, but what you describe in one aspect is a short and another a cross connection of power between the loops. If the track truly has not changed, I would look at the wires used to connect the transformer to the track and the connections. Might be something there.

Assuming there is nothing on the rails, be careful of trusting the voltage reading on the Z4000 controller, I was told there should be a load however small in order to get a reliable reading.

You do not say what kind of track and switches you are using. Switches can be wired to provide center rail power to all center rails on the switch. This becomes a continuity issue. If power can get to any one point it gets to everything. There needs to be insulators or complete gaps cut in the center rail to ensure an electrical break. Good luck hunting this down.

Thank you for your response and I will certainly check the track again. The switches although wired, are not currently connected to any source of electricity

@Richie C. posted:That would seem to eliminate the Z-4000 as the source of the problem.

Is anything else connected to the transformer throttle outputs besides the terminal blocks ?

Do you use a separate terminal block for each throttle and that terminal block only serves one loop ?

Is it possible you have a feed from one terminal block connecting to the wrong loop ?

Do the terminal blocks only supply track power - no accessories ?

What happens if you by-pass the terminal block that feeds outer loop "A" and just connect the throttle output that feeds that terminal block directly to the outer loop ?

Thank you for your response, and there is nothing else connected tot he transformer other than the two loops;

Separate terminal blocks are being used for each of the "A" and "B" loops;

Since I have checked the "A" loop, which appears to be the problem loop, I don't find any feeds from that loop to the "B" loop;

For loops "A' and "B", terminal blocks only power the track and no accessories. All accessories are either powered by an independent power source, or track power in the case of a gateman, but those accessories are on other independent loops , which are not causing any issues.

When is bypassed the terminal block for the "A" loop and connected the transformer directly to the track all that happened was that the amperage shot up and the red warning on the transformer glowed red.

If it matters, I am using Atlas shadow rail for most of layout

@Butchie posted:When is bypassed the terminal block for the "A" loop and connected the transformer directly to the track all that happened was that the amperage shot up and the red warning on the transformer glowed red.

That is the definition of a short. Somewhere you have a direct connection between hot and common. Every once in a while they can be intermittent which can be a real challenge to find. But kind of sounds like there is some resistance - if is was a direct short it would pop right away. Do you have any old wires connected. As they age, the insulation breaks down and power starts leaking through. Usually that causes the insulation to over heat and start a fire burning up the troublesome wire. You could touch various points/wires to see if any are getting hot. When the transformer gives you the red light does it also blow the breaker?

I have never heard of Atlas Shadow Track - I cannot find on the web - do you have a link?

K-Line shadow rail.

Thanks for the insight, at this juncture, I almost think I should rerun the four loop wires for the “A” loop. The Atlas track simply has a black center rail, which is not very noticeable once the ballast has been added. I believe shadow rail may be the term name for Lionel or Gargraves, track that has the black center rail, all of which I have used over the years.

Ok, I do own a voltage meter however, electricity is not my strongest area. I have spent some time on YouTube researching how to perform a resistance test but most of the videos appear to relate to the UK as opposed to USA. Are there some tips you can pass on to assist in performing the test on the terminal black wires connected to the track and the terminal wire to the transformer, thanks.

A picture of the front panel of your meter would simplify offering suggestions going forward.

PLEASE SEE ATTACHED ASTRO AI METER

Attachments

OL means there is not a circuit on a digital multimeter. The other possibility is it is out of range. So much for the internet for information. Now the question is where were the probes when the OL display was obtained.

Suggest getting back to basics. Physically separate the loops and use the same power source side (A or B) to check operation on each loop. Unlike O or 027 Lionel track there are no paper insulators between the metal ties which if bad can cause a short. If you are still displaying the same overload condition there is something physically wrong with a section of your track or your connection. Remove the power feed, put one probe on the center rail and then see if there is a connection between either outside rail and the center rail. My meter goes to "1" not "OL". The other thing you should do is touch both probes together to see how the meter responds to a direct short.

While the Z is not perfect I have found it to be quite reliable.

OL = Open Loop, ie. no continuity through the tested circuit or the resistance is too high to be measured by the meter. When the meter probes are connected one to hot and the other to common, this is what you want to see.

However, to find the source of what is causing excessive current flow from the Z4000, the opposite condition will be observed on the meter's display when it's probes are connected to any portion of the wiring or track circuit that is causing excessive current flow from the Z4000. If the meter reads 0Ω or close to zero Ohms, then that part of the circuit and everything connected to it can be suspected to be a potential cause of the short.

To save time diagnosing the exact location of a short, I like to divide and isolate the circuit somewhere in the middle (physically disconnecting wire and/or track) and check each half, one at a time. One of the two halves will show a short circuit (~0Ω) on the meter. Continue dividing the shorted half into progressively smaller sections (wire and/or track) until the bad component(s) is/are identified.

As previously mentioned, the cause could be bad wire insulation, a stray strand of wire touching an adjacent terminal, a piece of metal debris on the track or any number of other things that could cause unintentional conductivity between hot and common. Not yet mentioned in this topic is the possibility of a failed shorted TVS diode, if you’ve installed any. The divide and check methodical approach will help narrow down and identify where to look for the source of a short circuit.

Thank you both for your replies. When I took the picture of the voltage meter I simply turned it on and received the OL display, I didn’t mean for anyone to think I had actually attempted to perform the test yet.

I just ran the test using the Ohms/continuity setting. Touching the probes to the center and outer rail of the B loop provided the OL reading and no beep, is it correct that I should not receive a reading?

When I touched the probes to the center and outer rails of the A loop I received a reading and beep. What was interesting was that when I touched the probes to the center rail of the A loop and outer rail of the B loop I also received a beep and a reading. Would this last test confirm that somewhere along the loops, the A and B are inadvertently connected?

@Butchie posted:I just ran the test using the Ohms/continuity setting. Touching the probes to the center and outer rail of the B loop provided the OL reading and no beep, is it correct that I should not receive a reading?

Yes.

@Butchie posted:When I touched the probes to the center and outer rails of the A loop I received a reading and beep. What was interesting was that when I touched the probes to the center rail of the A loop and outer rail of the B loop I also received a beep and a reading. Would this last test confirm that somewhere along the loops, the A and B are inadvertently connected?

Yes. This means that there is a short between the A Loop center rail and the outside rail. This is the problem. The reason that there is continuity between the A loop center Rail and outer rail of the B loop is that the Outer rails of both loops are interconnected as they should be for a common.

Thanks for your quick response, so I guess my task for today is to crawl around the layout and look for the errant connection

I suggest to save time, start by disconnecting the Loop A center rail power drops from the distro block(s) or bus, one at a time and rechecking for continuity between center and outer rails. This will tell you pretty quickly whether the short is in the track or wiring.

That makes sense, and much appreciated. I will get on now.

Well that didn't take too long to isolate the problem. I took your advice and tested each of the four sets of wires from the track connections from the "A" loop to the terminal block and received a beep and reading on each pair of wires. Next, I discounted the four sets of wires from the "A" loop to the terminal block only leaving the pair of leads from the terminal block to the transformer but not actually connecting the wires to the transformer and the meter correctly retuned an OL reading. I did the same for the B loop and the meter did not return a reading on the four pairs of track wires other than OL. So the issue is not with B loop. I then ran test leads directly from the transformer to the "A" loop track center and outside rail and again, the meter returned an OL reading. The last step was to connect the "B" loop to the transformer and then engaged the "A" throttle and Eureka! the "B" voltage meter on the Z-4000 registered no voltage. I then engaged the "B" throttle and turned off the "A" throttle and no voltage was registered on the "A" meter. The last step was to engage both throttles and the trains ran independently of one another, PROBLEM SOLVED to this point.

My question to you is it ok to simply run new wires from the "A" track to the terminal block to bypass whatever short or issue I was experiencing or, will I end up in the same situation as before. I thought after installing each pair of new wires, I would run the meter test before I proceed to the next pair of wires to avoid the same situation as I just fixed. Therefore, if in fact a problem I could isolate it quickly, your thoughts?

@Butchie posted:...Next, I discounted the four sets of wires from the "A" loop to the terminal block only leaving the pair of leads from the terminal block to the transformer but not actually connecting the wires to the transformer and the meter correctly returned an OL reading.

Sorry this is unclear. Measuring what? The track, the track power feeders, the Terminal Block, and/or wires to the transformer?

A sketch showing which parts of the circuit remain connected and which sections were testing good and bad may be helpful.

Please refer to the attached sketch of the "A" and "B" loops. I was using the meter in accordance with the advice to test for resistance/continuity. The meter probes were applied to the four pairs of lead wires from the track to the terminal block for which I received a tone and reading on each pair. As the wire pairs returned a reading, they were removed from the terminal block until the only pair of wires remaining connect to the terminal block was the lead wires to the transformer, which those wires were disconnected from the transformer prior to testing. The meter returned no reading. I hope this further explanation along with the drawing helps.

Attachments

@Butchie thank you for the diagram. It is somewhat helpful. However, since I'm not there seeing what you're seeing, based on the descriptions you've provided, I'm having difficulty understanding what you're actually measuring at any given moment.

In order for me to help, you'll need to provide additional details as follows:

For each and every measurement, please describe in complete detail the interconnected and/or isolated parts of the circuit (meaning wire and/or track),

- To what exactly the Red meter probe is connected,

- To what exactly the black meter probe is connected,

- Whether the meter reads Continuity (yes or no).

Questions about your terminal blocks:

- Are they used for both Hot (center rail) an Common (outer rails) connections or just Hot?

- Do they look like one of these, and if so which one? If not, could you please provide a picture of your A terminal block?

Attachments

Thank you for your patience and I will try to respond to your questions as best as I can with more detail and photos. Please note that the photos I am attaching are after I had already tested each of the four pairs of wires connected to the "A" loop track and then to the terminal block.

The first step was to set the multimeter to the Ohms/continuity setting.

At the time all "A" loop wires were connected to the terminal block, I performed the resistance test by placing the black probe from my multimeter on the corresponding black screw of the of the terminal block's respective wire pair (e.g., track wires 1 - 4) and the red probe on the red screw of the corresponding wire pair being tested. If I received a reading on the Ohms meter, which I did, I then disconnected that wire pair and moved on to testing the next pair, each time I received a reading on the Ohm meter, I detached that pair of wires until all four pairs were disconnected from the terminal block thus leaving only the terminal block connections to the transformer (which I had mentioned in my prior message that I had disconnected the transformer from the power source prior to commencing the resistance test).

Having received your most recent response, I wasn't going to reconnect the four pairs of track wires back to the terminal block just to provide the attached illustrations. However, I assure you that the results of testing the four pairs of track wires provided the same results as when the wires were initially connected to the terminal block. Accordingly, the attached pictures depict the results of Ohm meter readings after the wires had been disconnected from the terminal block. for the purposes of responding to your most recent questions.

The terminal block I am using for the "A" loop is shown in the photo labeled Resistance Photo #1 ( wire all four pairs of wires disconnected from it) and you will see that the meter registered OL.

In the attached photos, each pair of "A" loop wires are numbered 1 through 4, and I tested each pair by placing the red probe on the red wire and the black probe on the black wire for which the meter returned the readings in Resistance Photos #s 2-5 (wires pairs 1 - 4 as labeled). I hope this additional information, coupled with photos, help to better clarify any questions or concerns that you might have. Thank you again for your assistance.

Attachments

Attachments

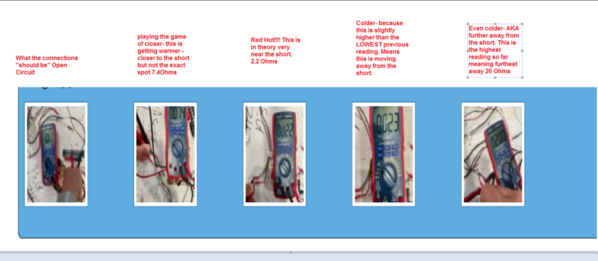

Thanks for the valuable tip, at least now I know where to start the search. The reading of 2.2 is associated with the track wire number 2 leads, which resides at the top of "A" loop, directly across from the transformer and track wire leads #4. I will retrace track wire #2 to try to identify any shorts or nicks in the wires.

@Butchie posted:Thanks for the valuable tip, at least now I know where to start the search. The reading of 2.2 is associated with the track wire number 2 leads, which resides at the top of "A" loop, directly across from the transformer and track wire leads #4. I will retrace track wire #2 to try to identify any shorts or nicks in the wires.

It's probably not in the wires. More likely in the track. Why? How could I know that from across the internet?

Resistance of copper wire is very low. If the wire was shorted, even at the far end, the reading would not be 2.2 Ohms, it would be far, far less closer to 0 Ohms. Copper wire #16 is about 4 Ohms per 1000 feet @77F.

In other words, if the meter was accurate, given copper wire, the short would be over 500 feet (since there and back 250 feet). Since that's not valid (this isn't 250 feet of wire in that segment), it means it's not in that piece of wire- but more likely the track. The track, being other than copper has a higher resistance value per foot of that metal. Also resistance adds at each junction.

Again, most likely NOT the wire.

Finding a short should not be as difficult as this is getting. I've stepped back from this because @SteveH has been providing great guidance, Your post about 4 hours ago it troubling to me regarding the understanding of electrical systems, particularly the "disconnected from the terminal block" and "disconnected the transformer from the power source ".

Addressing "disconnected the transformer from the power source" does this mean you simply unplugged the transformer from the outlet or does it mean you disconnected the feeds from the transformer to the track? Internally the transformer output is really a long piece of wire wrapped many many times around a metal core. Due to the length and gauge of the wrapping wire a small resistance may show up on the meter. Regardless if you are looking for a short the transformer must be completely removed from the circuit.

When I think about power feeds to track, I think about sections. One power feed to one section of track. The next section is completely isolated from the next and has its own power feed. Most people refer to these as blocks. Are you using blocks or do you just have multiple feeds for the track with no breaks in the rails? People either use a star wiring or buss wiring approach to supply power to the rail blocks.

With absolutely everything removed from the rails, check for shorts or any resistance reading between the center rail and either outer rail. And then check to see if the outer rails are connected to each other. If your see a resistance value there is a connection which should not be there. Disconnecting wires from the terminal blocks sounds to me like you started with all connected together made a check and pulled that set off the terminal block and moved on to the next set(s). It would be OK to pull all the wires off the terminal blocks and check each pair separately - assuming of course the feeds are connected to blocks.

Last comment, the feed wires shown in your last photo looks to be no more than 18 gauge. For short runs that is OK, but feed wires of a couple of feet or more need to be at least 16 gauge. You will see people using 14 and 12 gauge wire for this purpose on the forum. While I do not care for using 18 gauge feed wire, that is the gauge of wire supplied to pre-soldered track pins and those are no more than 8 inches long. I connect those short pieces to my 14 gauge power feed which is ultimately connected to the transformer. Jeff

Thank you Scouting Dad and you make some good points. To clarify my terminology, I should probably provide a little history. The track was laid and mostly wired over 12 years ago and remained dormant until I resurrected the project during Covid. With the exception. Of the recent “short” problem that has been discovered with the addition of the Z-4000, for intents and purposes, the layout is complete for operation of six independent sets of trains simultaneously.

The track feeds are simply four sets of wires attached at opposite sides of the layout. The four sections of the “A” loop are not as you call it “isolated” with their own power. All testing was conducted without the Z-4000 being plugged in and their leads from the transformer to the terminal block were not attached.

In the beginning of this evolving post the loops were somehow jumped together, but without a short?

You have eliminated that issue?

Now there is a short after "tweaking" the wiring?

Butchie, I've read through the entire post as it was happening. I understand you have 2 loops of track, the track previously was powered by an old Lionel transformer (presumably no TMCC). How are you able to have six independent sets of trains simultaneously? TMCC could do it. DCS could but not reliably with no break in the track - signal could slosh around like in a bath tub hitting itself from two directions.

If the trains worked previously (no shorts) with the old Lionel transformer, the Z-4000 would also work. That is assuming nothing has changed since the two were exchanged.

I understand you to say the A loop and the B loop are fed by several power drops and there are no blocks used whatsoever. I'll have to let the seasoned pros chime in on this but I don't think that is a good idea with modern engines. Post wars don't care.

If you are in fact running transformer control on post war engines and have a few passenger cars, three running at the same time would all depend on the voltage set at the time for speed; if so, most likely you are pulling 6 to 8 amps probably more.

I keep thinking I am missing something in your explanations. Just trying to help but really confused at the moment because things do not make sense. Jeff

Sorry, I am just responding to your last post but I have been preoccupied with getting my parents situated in their independent living facility. To answer your question regarding the number of trains I am running, as I already noted, I have a Z-4000 that handles the two large outer loops "A" & "B" . The inner loops are controlled by two ZWs and one GW180. The trolley has it's own transformer. Both the ZWs and Z-4000 are only set to run in manual mode currently until I sort out the electrical problems with the "A" loop.

I have exhausted my testing on the track and the can not seem to find the problem and I am at my wit's end with this project considering I had all the trains running just fine prior to introducing the Z-4000. I connected a pair of wires from the Z-4000 directly to the track and the train made it a quarter of the way around the track without any spikes in amps. When I added another pair of lead wires to the section beyond where the train stopped the amps shot up and the red the light flashed on the transformer. I am at the point now where I think I should rewire the outer loop, which I am prepared to undertake but want to ensure that I am doing it in the most efficient and effective manner. I was considering running a 14 gauge buss line around the outer loop "A", and then running feeder wires every six to eight feet from the track to the buss line. If I remove all the previous wire connections to the "A" track, would my short and the spike in amps problem be remedied?

I should mention that I have a pair of switches on opposing sides of the l outer loops that allow the train from the "A" loop to change to the "B" track and visa versa, and return to the "A" track at the opposing section of the layout. Although the switches are wired, they are not currently electrified. When I was initially using the the Lionel ZWs to power the outer loops I was having some interference when the trains approached the switches and after doing some research, I learned that I need to cut the center rail in between the two switches. I actually ended up cutting all three rails. Following this modification, I had no issues with the trains, shorts etc using the ZWs, the problem only surfaced once I started using the Z-4000, which I know is far more sensitive, than the ZWs. If I need to, I can remove the switches if that is the source of the problem and replace them with straight track sections. If I have to, I will gladly pay someone to fix this problem so that the hundreds of hours I have spent completing the layout will not prove to be a futile exercise!

Attachments

@Butchie In March you wrote "The crossovers are designed to switch the outer train to the inner loop and visa versa however; the crossover track sections are not being powered currently and their wires have been removed. Is there anything else I should be looking for? " I presume you are referring to the switch motors not the rails themselves?

If the connecting track between the A and B loop is cut as shown, zero power can travel from one loop to another, unless there is an engine straddling the center rails. Running transformer control you would want the voltage to be the same in both loops as the crossover is being made. Since you are using the "Z" there is no "phasing" problem. I run like this all the time with no issues. (I suggest you paste or insert your photos into your post as opposed to attaching a file which then has to be downloaded and opened. This is a snip of your word doc photo.)

When you say you have a problem when you added another pair of lead wires and the amps shot up, there is you short section. My guess at this point is you have crossed (or mislabeled) your track feeder wires somewhere. Easy to do if you have done any residential electrical work. (Black is hot, white is common. MTH uses Red as hot, Black as common. Took me quite a while to remember my buss wiring which uses black and white wire is reversed for the track power.)

You should also only have a single feeder wire for each block/section of track. The switches are often the places used for the block scheme. I currently have a single feed wire for a 36 foot long section of track that feeds into a yard which splits into seven eight foot + lengths of dead end yard track. No power supply issues.

I would ask what are all those tiny wires running on both sides of your track, but I might not want to know. And you have already ballasted your track? That makes things more challenging.

Lastly with all the transformers in use to run engines, there is the possibility there is a connection between out of phase transformers. That could cause the problems you describe. Fortunately that is usually an easy fix. Still the connection should be eliminated.

BTW - having had to move family members out of their homes, it is not a seamless transition - lots of stress. I would want to just run trains after that not deal with another problem.

Attachments

Thanks for your reply, the only track electrified currently is the outer loop “A” where I’m trying to research the short. The other small wires you noticed are various lighting and accessory wires, which run along the surface of the layout platform. I believe I failed to point out that my layout is not a traditional tabletop layout but instead, the platform or base (1 1/2" plywood) is affixed to the ceiling joist from the room below. The layout sits in a loft space above the downstairs living room, which was found by accident. When I had purchased the home I had inquired with the builder what resides behind the wall at the top of the stairway and above the living room and I was told it’s a large cavity that some owner’s finish out into a playroom for small children or use for storage. From the installed floor to the ceiling provides a height of about 5 feet. Accordingly, once the plywood flooring is laid down with few exceptions, there is no access to the underside of the layout. This issue has made it even more difficult to build the layout and run wires as I don’t have the luxury of the use of the underside of the layout platform. Consequently, I routed channels throughout the layout where wires could be recessed into the plywood foundation. It all has worked reasonably well other than having to climb in and out of the cavity and crawl around on my knees to do any work. The scenery, buildings and props are laid atop of homasote board to form small vignettes, which fit tightly together like a puzzle into towns, farms, street scenes etc. All the wires run under the vignettes and in some cases where permissible, under the layout foundation and through the wall to a central control panel.

Just to confirm, you see no issue with the crossover switches, which again are not currently electrified for the testing of the “A” loop and therefore, I should hold off on replacing them with straight sections. Assuming the newly proposed bus line is installed correctly, the old wiring on the “A” loop should not interfere with the new wiring and thus, I would bypass the existing short, correct? I have attached a few pictures to give you sense of the logistical challenges posed by a layout of this nature.