Always wondering what designs other folks are working on. Please share.

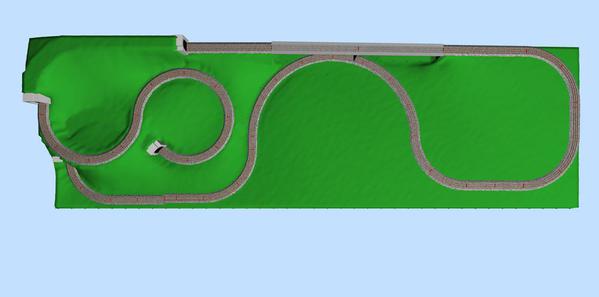

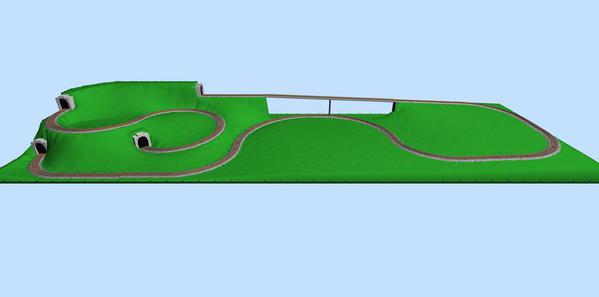

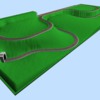

This is my grand design for the living room along the front windows. Train movement direction is counter-clockwise. It's about 55" deep and 160" wide. The entire platform is elevated to 24" in height so the right side can rest on top of the entertainment center cabinet. The center and left are supported by painted wood benchwork supports. The semi-circle in the middle is O-60 Fastrack. The curves in front and right are O-36 Fastrack. The switchback descent on left is O-31 Fastrack. My intent is to build this in October and start populating with Dept 56 Snow Village in November. The goal is for everything to be complete by Thanksgiving. The live Christmas tree will be positioned in the semi-circle at center. The tv will go on a custom platform at right so the train can loop around behind it. I have a few operating accessories like dump car and flagman. I may add some pushbuttons along the front for guests to have some interactive fun.

I would enjoy seeing your plans and/or works in progress