Parts have been ordered, enough to outfit 25 cars. I'll keep folks posted on my progress.

--PCJ

|

|

Parts have been ordered, enough to outfit 25 cars. I'll keep folks posted on my progress.

--PCJ

I wonder why Digikey ships with a signature? They leave packages here all the time, I've never needed a signature.

I'm not sure it's anything DigiKey did, as far as I know it was just a garden-variety Priority Mail shipment with delivery confirmation. It looks more like the driver simply didn't deliver and logged the notification to cover himself*, or he only rang my doorbell and didn't realize that either 'resident' could have accepted the package (my parents and I jointly own the two-family house)

---PCJ

*rampant speculation unsupported by actual knowledge/data

I don't see any LED's to light the cars. ![]()

Well, I'm using this model:

http://www.radioshack.com/prod...sp?productId=2062753

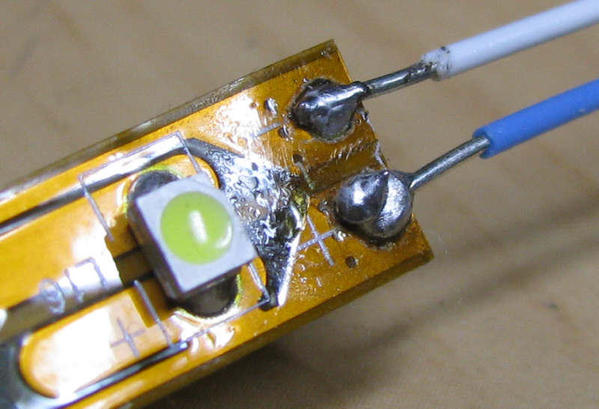

I did this with a 95-watt pencil (actually more like a cigar) iron that had a chisel tip about a quarter-inch wide:

I agree the bottom joint is a little sloppy, but I didn't have flux at the time (we tend not to need it where I work). For this project, I will have it (as shown in the photo), and a much smaller iron tip ![]()

And I watched this video:

---PCJ

I have a question about the constant current circuit if I may. Can a trim pot be used for R1 so the light intensity of the led strip is adjustable? If so what would be the recommended value? I was thinking of a 330 ohm trim pot but I'm not sure of the resistor value of R1.

I'm putting these in an old set of 16" Williams passenger cars I'm retrofitting for my son and would like to have the ability to dial in the brightness.

Thanks

Bill

Sure, you can also just "tune" the brightness with a selected resistor.

Thanks John

I have a question about the constant current circuit if I may. Can a trim pot be used for R1 so the light intensity of the led strip is adjustable? If so what would be the recommended value? I was thinking of a 330 ohm trim pot but I'm not sure of the resistor value of R1.

As John's schematic shows, the current is 1.25V / R1. So 62 ohms is 20mA (a popular value), 330 ohms is about 4 mA. Commonly available trimpots come in the 1-2-5 sequence or 100, 200, 500, 1000, 2000, 5000 ohms, etc.. So I suggest 500 ohms which would lower the current to about 2.5 mA turned full. But a trimpot turned full in the other direction results in 0 ohms which would try to force infinite current (i.e., 1.25V / 0) which would pop the LEDs.

You can set the trimpot to half-way (i.e., about 250 ohms) before applying power and start from there being careful not to go to 0 ohms. Or a common practice is to add a fixed value resistor in series with the trimpot. For example a 50 ohm resistor in series with a 500 ohm trimpot would result in a R1 range of 50 to 550 ohms (instead of 0 to 500 ohms). That would yield an adjustment range of about 25 mA to 2 mA.

If by "dial in the brightness" you want to change the brightness in operation (e.g., day-running vs. night-running), a switch to change R1 between two values might be more convenient. That is, you could simply reach under the car and slide the switch rather than lifting the car, flipping it over, and adjusting the trimpot.

Thanks Stan,

I didn't consider the 0 ohms scenario. I plan on giving these to my son. These are a late 70's, early 80's set of Williams kit cars I put together for him when he was a young boy. I plan on giving them to him when he's ready to put up his own Christmas display. He's graduating college next week for the second time so hopefully the time is close. I've upgraded the trucks and couplers, added vista domes to all of the coaches and observation car, now the illumination. I probably could have bought him a new set of cars for what the upgrades cost but it's more of a sentimental thing for both of us. It's pulled by a set of MTH ABA PA's that I repainted. The numbers on the A units are his birthday, the B unit is mine. Nowhere near prototypical but they mean something to him.

I like your idea of having two separate fixed resistors that can be switched in and out of the circuit to change light intensity for day/night running. This way I'm not building in a potential self destruct mechanism by turning the pot in the wrong direction. Thanks again.

Good catch Stan, I forgot about the zero end of the pot! ![]()

You can use a photo transistor and small reed relay to automatically switch from day to night, get fancy! ![]()

One recommendation for your packaging of the three components. I bend the leads of the bridge flat so that the total package of the regulator, bridge, resistor, and cap are a flat package. It's easier to conceal that.

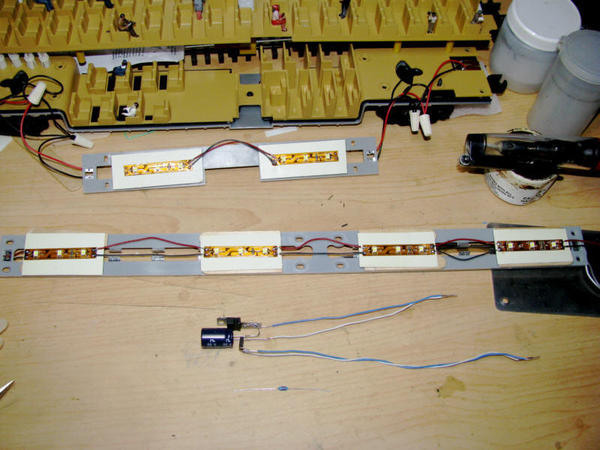

First light bars completed, with the regulator assembly below for comparison. The LED strips are raised on craft sticks and bridged with thin styrene from an ancient project that never got off the ground. This way I didn't have to fiddle with the projecting blades that the original lights mounted to.

I'm waiting on some connectors to join the upper and lower level lights--I decided that converting the existing power rails to supply the LED's would complicate matters more than simply tapping one point and running two leads to the upper level.

---PCJ

I roll-my-own connectors using snappable contact strips and heat-shrink. Makes small connectors that I can customize to any size I like.

Just curious, why did you break up the light strips and not run them continuous for more even lighting?

I guess I got fixated on the notion of only using a certain number of strips (4-6 when I first brought up my project). I'll try a continuous strip on the next car, and modify this one if the brightness isn't affected (which I guess that now you've brought it up, it shouldn't be).

---PCJ

Well, with the adjustable current model, a resistor change is all that's required to Crank Up the Light, ![]()

Lookin' good! ![]() I'd like to see an old car with bulbs and a new one with the LED lighting, I'm sure you'll be amazed at the difference!

I'd like to see an old car with bulbs and a new one with the LED lighting, I'm sure you'll be amazed at the difference!

One other tip, put white paper on the floor of the car, it'll make the light more even and brighter.

Last steps...

^ fitting the lower level light bar. The regulator sticks out from the right end

^ with the upper level reinstalled onto the chassis, the regulator assembly nestles neatly between levels in the hidden area of the carbody.

One last check, this time on track power.

^Carbody reinstalled and all lights connected on track power. (1.6 second exposure)

^Closeup of the lit interior. I thought the strips looked a little dimmer now that eleven strips are hooked up, but looking at the interior in a darkened room shows them to be "just right" in comparison to a real-life passenger car. I guess we're just used to toy (uh, er, "model") passenger trains lighting up the room like a traditional Lionel.

^And, by request ![]() a comparison between old and new. Not shown is the noticeably brighter lights in the older (silver-trucked) first-run Superliners. The unmodified second-run car's lights look brown by comparison. Both generations of incandescent-lit cars spill a lot of light outside the car, whereas the LED-lit one keeps most of its light inside the car.

a comparison between old and new. Not shown is the noticeably brighter lights in the older (silver-trucked) first-run Superliners. The unmodified second-run car's lights look brown by comparison. Both generations of incandescent-lit cars spill a lot of light outside the car, whereas the LED-lit one keeps most of its light inside the car.

---PCJ

You are not officially an LED lighting expert! ![]() Lookin' good!

Lookin' good! ![]()

"Now officially"

Fixed that for ya ![]()

I think I'll summarize my learning process on the 3-rail forum for the benefit of those who may not have peeked in the electrical forum.

---PCJ

Looking good, and thanks for the "fix". ![]()

RailRide

One question: With the constant current config and the 330 Ohm resistor, at what voltage do the LEDs turn on? I am trying to decide whether to wire the LEDs like you did vs. bypassing the resistors on the strips as discussed earlier.

Thanks

Bob

Since I cannot use these in my prewar cars. I use two strings of these to light the underside of my layout.

RailRide

One question: With the constant current config and the 330 Ohm resistor, at what voltage do the LEDs turn on? I am trying to decide whether to wire the LEDs like you did vs. bypassing the resistors on the strips as discussed earlier.

Thanks

Bob

If you are running conventional, you might consider a voltage doubling circuit to allow the lights to light at a lower voltage. Here's the circuit for that. I'd use 220uf 50V for The left-hand cap and 100uf 50V for right-hand cap to start. The transformer source is just the track pickups, no need for a transformer there.

RailRide

One question: With the constant current config and the 330 Ohm resistor, at what voltage do the LEDs turn on? I am trying to decide whether to wire the LEDs like you did vs. bypassing the resistors on the strips as discussed earlier.

Thanks

Bob

Apologies for necro-posting, but I thought this was relevant, since I just noticed your question had not been answered (dunno how I missed it a year ago), and it's a legit question for anyone looking at this thread for info. The LED strips power up rather early on the Z-controller's range of travel. While I haven't measured the starting voltage, I don't think you'll be able to get a passenger train moving before these lights come on, and they light up at the intended brightness at whatever minimum voltage is needed to turn them on.

John, when I tried the voltage doubler in Conventional, the constant current source got very hot at full voltage!

It depends on the current you draw Dale. Also, you can use an LM117T for your constant current source for higher currents/voltages. I've started using them if it looks like more than a about 250-300mw being dissipated by the constant current source.

Ok, so to use a system as you've descibed on a conventional layout...18v max roughly...is ok and that should work for command as well- right?

Next question from the electronicly impaired{me}- how low a supply voltage to get full lighting on the cars...3v...6v...9v...? I really want to get my passenger cars and cabeese lighted better at lower voltages when the engines are crawling around...or as bright as possible.

I finally got to use my multimeter on a model-RR application ![]()

Here's the finished Sightseer Lounge upgrade:

This setup has 12 LED segments fed by the onboard regulator pictured on Page 3 of this thread. Eight segments on the upper, 4 on the lower, and it lights up to working brightness at 9.9 volts on a Z4000 (I couldn't get it to output anything lower with just the single car) and just before the first yellow mark on the dial of the Z-1000 I use for testing my upgrades.

As I thought, one probably won't get a passenger train moving on less voltage than it takes to light these up (they don't dim unless power is removed and they've discharged the capacitor)--unless you're using locomotives with extremely low voltage requirements pulling featherweight coaches.

Here's a closeup, with the lights shining through the slot in MTH's light bar

In fact, this arrangement works so well, I'm going to use this method for the remaining upgrades.

---PCJ

I finally got to use my multimeter on a model-RR application ![]()

This setup has 12 LED segments fed by the onboard regulator pictured on Page 3 of this thread. Eight segments on the upper, 4 on the lower, and it lights up to working brightness at 2.5-3 volts on the Z-1000 I use for testing my upgrades. As I thought, you won't get passenger cars moving on less voltage than it takes to light these up at full brightness.

Many hobby multimeters have a hard time measuring the AC voltage from a chopped-sinewave controller like the Z-1000. Without getting into an arcane discussion about "true-RMS" meters, suffice it to say that even though the meter is reading "only" 2.5-3V, there are short pulses on the track voltage that are 15V or more. It's these pulses that provide the necessary voltage to illuminate the 12V LED strip. A "pure" sine controller like the Z-4000 does not have these short high voltage pulses so given the same meter reading, the LED strip would not light up.

The voltmeter I bought mentions "DC or RMS AC" in its list of input measurements, along with markings on its dial indicating voltage as "V~" (which I assume is AC) and "V" with a solid line over a dashed one. I was under the impression that it was accounting for the Z1000's output, but then again, I hadn't tested the cars on a Z4000 at this point.

I took the car to the test track and hooked it to the unused handle on my Z4000. The car lit up at 9.9 volts, I'm not sure at what point it actually starts at since the Z4000 didn't seem to want to output anything between 9.9 and 0.1 with just the single car (does the '4000 need a real load on it to output anything less? I've never used it in conventional). I've amended the post to indicate a Z4000's results and revised the Z1000's figure to a position of the controller's rotation.

I still think a passenger train heavy enough (like the Auto Train) to benefit from LED lighting would find it a challenge to get moving without the cars lighting up. If you're running 2-3 cars behind a Beep/f or a starter-set truck-mounted can-motor unit like the Lionel GP38, RS-3 or K-Line MP15/S2, then I guess one could have have issues keeping them lit at low speeds.

RMS AC and True-RMS AC are different in the measurement technique. The True-RMS meter will give significantly different readings on chopped wave transformers than a standard AC voltmeter.

Is "True-RMS AC" a standardized description (i.e. will you see the phrase on the meter and/or documentation) that one can look for, or is it just a charactereistic of (I assume) higher-end models.

I'm still wondering what the "V-with solid-over-dashed-line" symbol means. Might as well confirm what "V~" means while we're at it.

---PCJ

A meter that does true-RMS measurements will state it in the specifications. I don't know if all of them will say it on the meter itself, my bench Fluke does say True-RMS, but that's a sample of one. ![]()

gunrunnerjohn,

Does thr formula for I-out on page 1 also apply for the LM317T--or is there a different formula for I-out for the LM317T?

The formula is good for any LM317 variant.

Access to this requires an OGR Forum Supporting Membership