What's the difference with the 773 Hudson's.

Valve gear support. They show different ones are they inner changeable?

|

|

What's the difference with the 773 Hudson's.

Valve gear support. They show different ones are they inner changeable?

Replies sorted oldest to newest

There are two PW 773 variations. Basically delineated as the following:

The 1950 Production run has a fancier valve gear assembly and came with the premium 2426W tender.

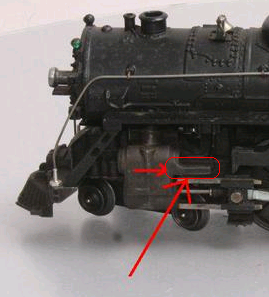

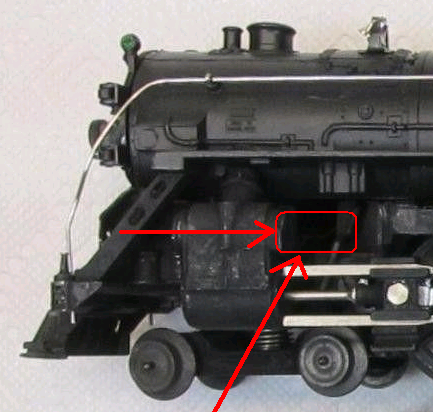

The Fancy Valve Gear:

The 1964 production lacks the fancier valve gear and came with the PENNSYLVANIA 736W or NEW YORK CENTRAL 773W tender.

Lacking the valve gear:

The parts list shows 773-55 as the valve gear support for both the 1950 and 1964 versions... can you elaborate?

If putting together an LIT version, you are not building a 773, but a 783, 784, or 785. These use some of the "same" and some different parts. Here is the correct parts list and exploded diagram for what you are seeking.

https://www.lionelsupport.com/...s/108606Complete.pdf

Thanks b.

It was listed as a 773. Thanks for clearing that up.

It has the 773 type motor coupling. Lionel put a bone type in later.

If it is newer and marked 773, it could be this:

https://www.lionelsupport.com/...da-8aed-11e12d169221

I notice through out the parts list this loco is described as a “metric” Hudson. That should jump out at you as you work with the screws and nuts.

That I have from Lionel site. And I was using that. As an example.

The first picture I posted is from there.

Part no on package

6108005500

Then saids hudson#.5340 . I think it's a 3.

5340 would be a 700E remake: https://www.lionelsupport.com/...94-8d1d-48591eea334f

Still in the "scale hudson" family, but there are nuances between each.

You should really determine what it is you have (exact product number such as 6-18005) to ensure parts comparability (and re title the post accordingly as well)

What Boiler are you attempting to mate that frame with? That frame belongs to the 6-18005 700E remake. If all you have is that frame, you would probably be better off purchasing a complete locomotive vs sourcing all the parts to complete your 6-18005 700E remake.

You could buy the Vision 700E for less than all the separate parts will cost you to make a 5340 1990 700E.

Pete

Not sure on the boiler.

Norton I'm starting to realize that.

If I had a 3d printer I would print a boiler

The 773 boiler won't work?.

Whoa!.

I have tin plate boilers that I can mod better than that.

I thought the 6-18005 was now in bargain territory? Surely used Hudson’s are not competing with the new Vision stuff?

I do know the B6 switcher has descended into ridiculous territory, some going for $160 or so. I am done accumulating, but am sorely tempted!

The way this is going. This is going to be a frank.n Hudson.

No electronics. Smoke only.

Not sure I’d call 550-600 bucks “ bargain territory “ for the 18005, but I can promise the OP would well surpass that number trying to piece one together from just a bare block and wheels....the motor alone hovers in the 100 dollar neighborhood........Pat

I'll be somewhere in that range.

I have seen the 6-18005 go for as low as $300.

bob2 posted:I have seen the 6-18005 go for as low as $300.

Thats about what I paid for mine, unrun with a case and nameplate.

Pete

Do you know where that eccentric came from? Doesn’t look like the OE part from 6-18005.....not all parts from the early 700E’s be it original or reproduction aftermarket parts are compatible with 18005....some are, some are not...I’ve had to machine down the heads on some replacement bolts, but never that much...that looks grossly out of whack......Pat

This is what the proper part looks like:

Also, it isn't apparent that the sleeve is installed:

Harmon that is what I'll probably end up doing.

B4. That is what is in there.. Sleeve is there. But the crank might not of got Countersunk right

The sleeve was on crank.

Thanks guys.

I have a different part no. for the eccentric rod bolt according to the Lionel service publications from 1990....correct part no. is 610-8005-517.....now, Lionel may have superseded the old number with 610-8045-527, and they may have never bothered to check fitment. Also of note for the OP, not all 700E eccentrics are created equal, there are more than one eccentric bearing 700 prefixes....6-18005 calls for eccentric part # 690-700E-046, while Hudsons # 783,784, & 785 call for eccentric part # 700E-241........hope this helps.......Pat

Good point on the crank @riki. This image is not the exact crank you have, but is representative and displays the alignment pins that must properly seat in the wheel:

Those pins must rest in the depressions in this representative drive wheel:

@harmonyards, following the full thread, you would see it has been determined @riki is building off of a 6-18005 frame, thus the postwar and MPC service diagrams (that even I posted and suggested before narrowing down what was had), are may not necessairly applicable. We all should be working off of the 6-18005 as broken down here: https://www.lionelsupport.com/...94-8d1d-48591eea334f and here https://www.lionelsupport.com/...201-8005Complete.pdf

bmoran4 posted:Good point on the crank @riki. This image is not the exact crank you have, but is representative and displays the alignment pins that must properly seat in the wheel:

Those pins must rest in the depressions in this representative drive wheel:

@harmonyards, following the full thread, you would see it has been determined @riki is building off of a 6-18005 frame, thus the postwar and 1990 service diagrams (that even I posted and suggested before narrowing down what was had), are not applicable. We all should be working off of the 6-18005 as broken down here: https://www.lionelsupport.com/...94-8d1d-48591eea334f

Clearly he’s working on on a 18005 chassis....the part no.s referenced are from the 1990 service publications. ( date of mfg.) as you and riki have possibly pointed out, this may be as simple as the eccentric not sitting in the slot properly. However, just because it’s on Lionel’s web site, doesn’t mean the parts are 100% accurate....there very well could be superseded part no’s since they don’t list the original 1990 eccentric bolt part no. by they’re own service publications.....surely you’ve run into this before.....therefore, if his eccentric crank is sitting in the slot, then he’s clearly got a parts incompatibility issue.....as I’ve said, not all 700E parts are created equally.....Pat

I checked my old modern era parts guide and come up with 610-8005-517 for the eccentric rod bolt for a 6-18005 Hudson. The new number may have superceded it, but it's not correct. Happens a lot in the automotive industry. New part is recommended as a replacement but doesn't fit the same as the old one.

Bolt length could be different. In the photo the -527 appears to have a larger bolt head than the -517 part.

bmoran4 posted:I am curious as to what the difference is besides thread locker and camera angles?

That’s a good question, I think the one thing we can agree on, is the fact Lionel does some goofy stuff with their parts dept. ....or at least I hope we can agree on that....I’ve never trusted the breakdown on Lionel’s website for that engine because of the inconsistencies in the part numbers vs. the publication of when it was actually manufactured...I’m asking your opinion, do you think the part no. change is because of the locker addition?....seems silly, but possible??...no?.....Pat

Since the OP was asking about a 700E, I went and looked at a 1939 700E. The correct fastener would be 700E-44C. I went and looked and found that some of my spare screws would be a problem. See photos below. I would have though the screw pictured above was the cross head guide screw, but I have no experience with the 18005.

The upper screw is from an unknown source, but clearly could be a problem. The lower screw is a proper eccentric crank screw for the 700E. Below that are Lionel drawings for the screw.

Thanks all for the response... Yap. Jeff Kane has his own part number system for somethings. So saying need this number. His is something else.

I think I have a 5c collet that can hold that bolt. I can shave it down a bit.

Taking down the head works.

Ps.

Jeff told me others have complained. Lionel.s reply was they wanted to keep the look. Instead of using a flathead screw.

So. It's something we have to modify to work.

riki posted:Taking down the head works.

Ps.

Jeff told me others have complained. Lionel.s reply was they wanted to keep the look. Instead of using a flathead screw.

So. It's something we have to modify to work.

That’s cool, I’m glad you were able to come up with a remedy riki, .....I’m curious on how you did your part number referencing.........did you rely solely on Lionel support off the website, or original documents from the 90’ parts breakdown? How did you come up with part numbers piece by piece? .......the reason I ask, in the picture you posted of the bolt not being able to pass by the rod, the eccentric pictured has the rod riveted on. The OE 90’ model has a separate screw that attaches that rod on the small end of the eccentric. I’m sure the OE part is NLA, and it’s substituted with another part.....I’m guessing you got all your parts from Jeff?....what was the part no. for the eccentric that was sold to you? .....if you don’t mind me asking....these tidbits of information might help the next guy with a broken part from 18005....Pat

Wait till you see what color the boiler will be.

I think it will look sharp. But not original.

Still haven't figured out what smoke unit. The smoke lever is hard to find.

I can work up a cam with a switch. Like STD ga. Chugger . to work an MTH unit I have.

The original has the circuit board which I don't want.

I have rods voltage reg. To make up or. I have the Asian regulator. Forget what they are called.

”Still haven't figured out what smoke unit. The smoke lever is hard to find”

how many do you want? ...😁......Pat

“ But why a large head on bolt. When others are thin.“

because you got a mix of reproduction parts ( made from an outside vendor) & a mix of LTI parts thrown in for good measures.....no harm no foul, you figured out how to get around that big headed bolt just fine....I’m glad you were able to come up with a rotating assembly now....Pat

Thanks Harmon.

Lionel sent me the 700e diagram. With parts list on their site.

What I'm missing is

Part. 690.700e.218. And

690.700e.066

And 690.700e.219..217

If I can get them. Fine. If not. This works.

@riki , I guess you missed the Lionel Support link to that document was posted yesterday...

bmoran4 posted:We all should be working off of the 6-18005 as broken down here: https://www.lionelsupport.com/...94-8d1d-48591eea334f and here https://www.lionelsupport.com/...201-8005Complete.pdf

Thanks b4.

We are on same page now.

You can try forum sponsor @S AND W for the parts you are seeking. Bill is pretty responsive to email: http://www.sandwparts.com/Parts%20List/6-XXXX-XXX.pdf

Ok ..thanks

riki, looking at the photos you’ve posted, and the parts list you got from Jeff, some of the parts you are looking for, you’re not going to be able to add them .......looks like Jeff sent you eccentric assemblies 763-216 & 217.....these are not the “fancier” 700E type eccentric assembly that has the extra arms to add things like the valve stems, the lubricator lever, and the combination lever.....your rotating assembly as I see in the pics, has more in common with the 785 Hudson ( 6-18002 ) then a 700E......unless you’re trying to go back and replace all of the eccentric parts, you can’t add the others...they all link off that specific 700E type eccentric assembly............Pat

Pat. Thanks

Buying the other rods to have. 700e. 216 ..217 Plus lubricator.

The pick ups are hard to find.. Might have to mod a diesel pick up.

The side rods were a pain. Had to shim.

I think the blue on threads. Is to turn the screw in a little. To set clearance.

I took it off cause I didn't want to cross thread ..it felt tight going in.

This thing is going to be a crawler. Using 3/4 stack. Motor . just ran it holding it

The 700e also has more hand rails and piping. More trim in general.

Hudson guys.

What is the size of screw for the turbo generator

And is only one used?

Thanks..

Hold it.. Ok...turbo goes on left.

What I was looking at ..is they put the screw for it on other side of page. By the reach rod.

That part that track rod goes into is that cast into the frame?.

I don't see a part number for it

Not quite a Hudson....

I'm a little late to the Hudson party, but have a couple of comments. Where to start.....

To answer Bmoran's question, The 2 center wheel eccentric crank screws look the same in the above picture, but not. The 610-8005-527 screw is american SAE thread. It is used on drive wheels that are pressed on the axle. The 610-8045-527 version is metric thread and used on wheels that screw on the axle, starting with the Commodore Vanderbilt 4-6-4.

Picture #1 is pick-up assemblies and rollers. Since you have already mounted FM pick-ups, all that is needed is to change to rollers. They will fit the diesel pick-ups.

#2 is the correct smoke lever assembly.

Picture #3 and 4 are the valve stem and oilier linkage. These parts will not mount on the 763 valve gear supplied by Jeff. The valve stem is not even visible behind the valve guide casting. You could leave them off and no one would notice.

The power reverse cylinder is mounted with a #3-48 x 5/16 phillips oval head screw.

Below are some close up pictures of the valve gear that I added to a stock 783 some years ago. I added as many 700E parts that was possible while keeping the cast wheels for magne-traction. I took out the electronic whistle board and added a 773 sound card.

Did the drive rod hit the head of the bolt on the side rod?

Dave looks that way.

Armature is getting hot. After about a 15 run.

Armatures run hot. A postwar armature is probably rated at 60 degrees C, or about 140 degrees F. A modern armature could be rated even higher. You know you are in trouble when either smoke comes out of the motor or the solder on the armature coil attachments melts and is flung out. If it is not so hot that you can hold your finger on it, it should be okay.

That's the problem. Touch it and it's hot. Can't keep the finger there long. The motor is new 3/4 stack. I might send it to hannon. Have him look at it.

Maybe bump up to full 1 inch stack. I have an 1 inch or 1-1/4 stack around somewhere. I had Bob wind for my STD motor I was working on.

Make sure your mechanism turns free....and nothing is binding. Remove the motor mount bolt and slide the motor back far enough so you can rotate the worm shaft with your finger tips. Should spin smooth through a full rotation. Any spots that bind are going to result in poor performance and overheating. Also check the motor spins nice and smooth by hand. Infact, that locomotive when all assembled, should be back driveable....in other words, you should be able to rotate the wheels by hand with motor and all rods installed....it might be that all the parts are so new it just needs to break in....if all checks ok, you could fashion a way to suspend the drivers off the rails and allow it run for a while to facilitate a break in period use jumper wires to run to the hot & common.....in your video, it doesn’t sound abnormal for a coffee grinder motor....😉.........Pat

I interpret Riki's first picture different. Hitting a side rod screw will not cause the rod to snap like that. Did it snap the first time you ran it under power, or did the rod break when it fell over? What transformer are you using?

Thanks Pat.

Chuck. It was running. A few laps before it fell off track.

The side rod screw was loose. So I had to shim it.

Maybe I should get another side rod and file it down .. Never thought about it bring to thick.

Cause you can't tighten the screw ..otherwise you tighten the side rod to wheel.

That rod would stretch a mile before it broke like that....the small end or the big end would have opened up before it broke like that....there has to be some extenuating circumstances for that failure....riki, did you shave the back side of the rod to clear something? ....like the rod bolt?....that’s a crazy break........Pat

No, I'm not saying the rod would stretch, but buckle from the piston rod jamming in the cylinder hole, from it not being drilled deep enough. But if it ran around for a while before it broke, that's not it. If you can't tighten the side rod screw down completely without the rod binding, it's not the right screw. I wouldn't file the rod down any. What transformer are you using?

Yeah, I’d agree with that Chuck, it surely would bow .....It is a sheetmetal rod he’s using.....not the cast rod...I’d think it would have even kicked it out of the cross head guides and maybe snapped off the pin on the crosshead before shearing a rod like that....Pat

700E connecting rod and main rods are cast. I wonder if the rod bushings are installed in the connecting rods? To my eyes it looks like the rod bowed inward then snapped. I see no scraping or gouge marks where the rod broke.

I vote for the side rod screw backing out and chopping that rod. I bet you can find munch marks near the break.

The forward crankpin is always problematic - our five foot gauge doesn't help clearances. Note that the otherwise nice MTH Hudson has off-center crosshead guides and piston rod holes.

Yes, file the rod and bolt head. Make sure that it has clearance with driver shoved as far to the side as it will go.

Reproduction connecting rods are stamped sheet metal Chuck....he got them from Jeff.....I can’t tell what the main rods are from the pics........Pat

He might have gotten cast rods....looking back at riki’s shopping list from Jeff, it doesn’t say whether or not they’re repros..........I’d bet Bob is right ....the forward bolt must have had a field day eating the rod....and if it was cast, it probably made short work of it.........Pat

If the broken rod was stamped, it would't have broke like that.

True that Chuck....I’d like to see the back side of the rod ...see if something helped the failure along.......Pat

Thanks guys

It looks cast. I just received the cast wheels from Jeff.

The end wheels have a stud.. Where as the 700 are screwed into the wheel

I like the cast wheels. I hear they are a pain to deal with.

So but. . Will go that route.

I threaded a washer on the screw. That let me tighten the screw. The washer fits behind side rod. Was a little trying but I got. Ran fine .except for Armature..

Have a question. Can the 773 wheel fit on the 700 axles..

Looks like the 773 holes are larger.

Well. Can't swap the wheels.

But took the thins apart .. The wheels still were not turning that freely.

Now they do.

I filed the inside of the side rod. Down pasted the casting marks. Rolls freely.

And I can tighten the screws. No shims.

I don't understand what you are doing. Are you planning to replace the spoked drivers on the chassis you have shown us with solid cast drivers? Why?

Chuck.. I like the solid cast wheels. And I was going to magnetraction . but can't do it

So I'm stuck with spokes. Unless I. Can use the 773 axles. Then magnetize just the solid wheels. If that even would work.

Riki, If you try to use other parts from other engines you really need to be up on your game. You are opening Pandora's box. If you try to use the 773 wheels, you are going to have to change the axles, which means you are going to have to change the axle bearings in the frame. Then you are going to have to change the worm wheel on the geared axle. Then you are going to have to re-quarter the wheels on the axles. It would have to exact the first time, as you only get one, maybe two, attempts as the wheel will work loose on the axle and slip when the engine is under load. The quartering must be precision as the rod bushings leave no room for any slop. This is probably why Lionel sells the frame with the wheels already installed by a machine.

Thanks Chuck.

Yeah I'm stuck with a mess. Leaving as is.

Roy boy I might paint the wheels red too.

It is, after all, a hobby. I have a Tuscan K4, and a purple three cylinder 4-10-2.

There is a actuating arm that is attached to the crosshead that pushes the lever forward and gravity brings it back.

Thanks Chuck.

the one I have binds in the steam chest. It actually lifts off the guide. So the rod must be off center.

But that's hard to tell. Cause I checked. I'm using one without that bar. And no problem.

I'll take a picture.

If it doesn't go in all the way, maybe that caused your rod to snap? Run a drill bit through the piston hole and see if the piston rod will finish the travel, on both sides.

The right side broke.

I have the piston working now. But won't know till I run it.

Trying to figure out wiring now.

E unit has a short black wire with a solder lug. Don't know if it's ground or hot.

Then the wires from e unit.

2 black wires

White

Green

Yellow

Blue

Thanks Chuck.

That's the piston I'm using. So far by turning wheels it works. Should have this test running by the weekend.

Where is the black wire originating from?

Chuck. It's tied in with the other side of e unit coil. The wiring for the 773 doesn't have it.

Only thing I can think is that . the field wire is replaced with that.

The motor I have the field wire is grounded.

Where as the 773 field wire goes to the plug solder tab. On left.

I think it is the reverse unit coil ground wire. It would normally have a solder lug on it a mount to one of the gearbox screws.

Thanks.

I will keep searching. A call to hannon..

Ricki,

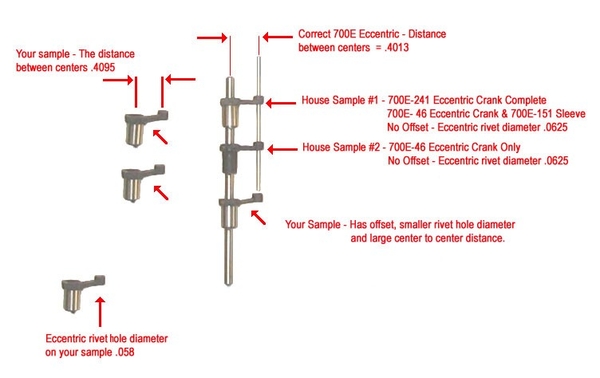

Sorry that I'm late to the party, but I did come across a problem that I think everyone has missed. Your trying to mixed rods and valve gears from different eras, especially the eccentric crank. Lionel faced essentially the same problem (rod clearances) when recreating the 700E in 1990. Their solution was to create an offset of the arm on the eccentric crank. Jeff Kane bought a number of these eccentric cranks and sold them as 700E parts, when in fact they were not backwards compatible. I know because I created the comparison years ago. See below.

This offset allowed Lionel to create the side view illusion that the rod configuration was the same as the original 700E, however one only needed to look from the top down to see that the rods were not running parallel.

Access to this requires an OGR Forum Supporting Membership