Lee

In the distant past I have successfully paralleled two 180 watt PoHos linked to a TPC 400 to achieve the so-called "super power" as well as a pair of 135 watt units linked to a TPC 300 [originally shown in a IC Controls video demonstrated by Lou Kovach and produced by the OGR Webmaster].

Although my 180 watt units, equipped with TVS, had a very quick acting breaker, at the higher amperage loads I still got a very significant arcing upon a derailment pre-trip. It did leave marks on the rails. [O-gauge welding].

As Chuck notes control of the your 180 linkage depends on the circuitry of the ZW L?

The paralleled 135 watt units linked to a TPC 300 producing 15 amps were far more practical for my use. However, the 135s do not trip nearly as fast as the 180 units.

In any event only fixed voltage transformers should be paralleled. According to Davis Electronics, Jim Barrett''s employer way back in the early days of paralleling PoHos, circulating currents can develop in pairing variable voltage transformers.

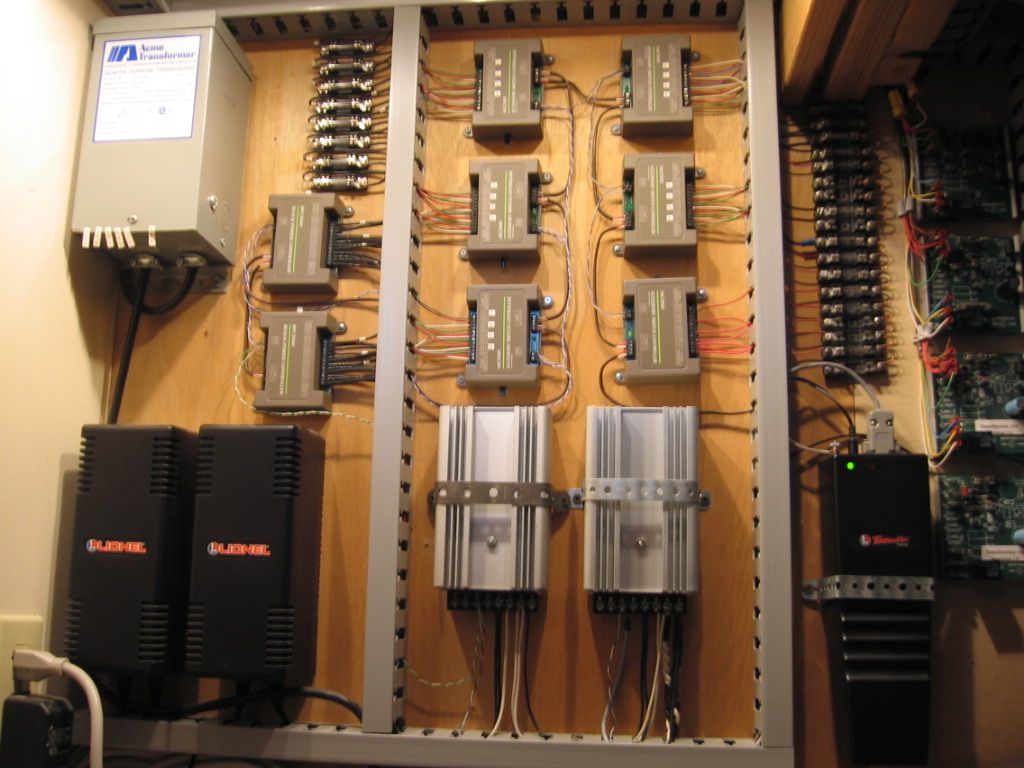

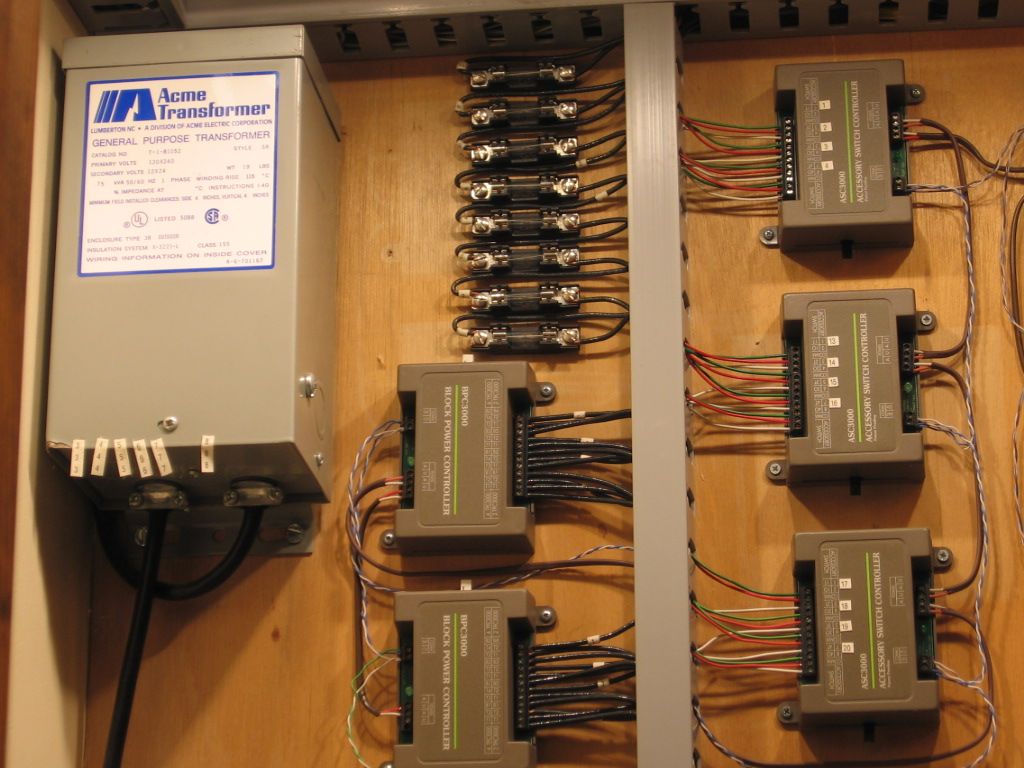

Photo below of my 1997-built layout's control "panel" shows the array of Powerhouses and Track power Controllers that I experimented with. In the end, for my layouts, I settled on 10 amps per power district, each supplied by a single 180 watt PoHo.

[the two 180 watt units on the lower shelf with the red and white labels on the end, were the early issue "out of phase" PoHos that I opened and rephased--as so marked]..