I'm headed into uncharted territory and need some help with using Arduino to control two DC motors.

I think my components include:

- Arduino Uno or Nano with an L298 and two axis resistive joystick controller

- Pololu #1595 1000:1 ratio micro metal gearbox HP 6V

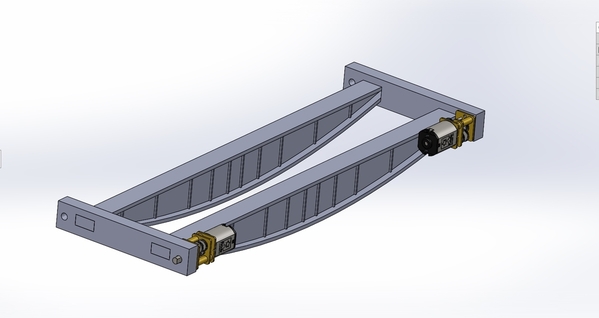

My main question is whether or not I can use the L298 to make two motors spin at the same speed at exactly the same time. Can I use the L298 and Arduino Uno to spin each motor at the same speed at the same time? Each motor would be driving a wheel in this application and they have to move in perfect unison so the vehicle doesn't bind on its rails. I'm sure this question is an obvious yes but I'm in the beginning stages of this project and don't want to start by assuming instead of confirming.

My second question is what benefit do I get some using the Pololu 3081 encoder? As I understand it, I can read the pulses (steps?) with my Arduino to detect my position along the path. Does this mean I can set a range for how many revolutions the motor can make (and therefore how far the vehicle can travel)?

I have not looked at or figured out if an Arduino Uno/Nano with an L298 can drive one or two Pololu 1595's or understand input from the 3081 encoder. I'll figure that out once I know if I can control two motors in sync.