Myles, that model engine looks fantastic. My vote is to continue the description of the restoration. I always learn from your modeling methods.

Based on two votes I will continue journaling the S-38 saga as part of my larger story. The patrons are pleased with how I'm approaching it.

Trainman2001 posted:

IIRC, you can see it on display as part of the Frank Lloyd Wright-designed Johnson's Wax Headquarters building tour at Racine, WI (not to be missed, BTW). They built a whole rotunda to house it.

If you go, don't miss the research tower tour. A skyscraper that has only one small entrance door. No longer used, since it obviously fails fire codes. You can get a tour, though.

Myles - you look like you are having way too much fun...![]() . You've certainly taken modeling to a very high art -- the 'night' shots of the engine house could easily be mistaken for the real thing (probably not enough trash around the outside...). Its just terrific.

. You've certainly taken modeling to a very high art -- the 'night' shots of the engine house could easily be mistaken for the real thing (probably not enough trash around the outside...). Its just terrific.

I have a couple of 3-D printing questions for you -- since I don't have a printer (and at this point, I don't plan to buy one), these may be uninformed. You mention using sketchup to do the 3D modeling. As a woodworker, I use sketchup all the time - it really is the greatest thing since sliced bread - especially since its basically like doing the real woodworking, in terms of joinery, etc. (less risk of cutting your finger though). So does the 3-D printer/computer use the sketchup file (*.skp) directly, or do you have to convert it? What's the finest detail you can print (in terms of actual size). I guess a better way to ask this is what is the inherent resolution of what you are able to print? I suppose that depends on the plastic feedstock? 1/128 inches is 7.8 mils or ~200 micrometers (human hair is about 100 microns, plus or minus) -- so if the part is not self-supporting, can you get to 100 microns or a few hundred microns or ?

You must completely finish the drawing in SketchUp ensuring that is a complete solid object and has no reversed faces. Solid means that if you filled it up with water nothing would leak out. Any small section that's not touching another edge or face would create a leak and would therefore not be printable. You then have to export it to an STL file converter. In earlier SU it was a free add-on. In the current version it's included. The SLT creates a 3D model describing all the exterior surfaces that can be interpreted by the slicing software. The slicer then creates the individual layer geometry that the machine uses print the object.

The resin printing system can produce layers down to 10 microns. I find that free-standing objects much small than 1 scale inch in O'scale are very fragile. If they're supported they will be okay, but if they're just hanging out there, they will break off. 100 microns is the best most string (filament additive printers) are capable of which is why I waited until resin printers were available at low price points to do the railroad stuff I'm now doing.

Myles - thank you. Its interesting/encouraging (to me) that one can use Sketchup to create the actual 3-D drawing. I should quickly note that looking at the pictures of the diesel engines and the wheel lathe shown earlier, you've got some serious 3-D computer modeling chops - that's not easy in any rendering environment. One thing I've discovered about Sketchup is the 3-D model warehouse where you can often find models that are 'good places to start'. Still, Sketchup has a pretty non-linear learning curve - some parts are easy and some are more like steep cliffs... (that I keep falling off if I haven't used that particular skill in a while...)

You mention 1 inch rendered in O-scale (= 1/48") is about the smallest free-standing objects that aren't too fragile. Just to turn that question around a bit -- what's the smallest object or feature in the 1:1 world you think is worth 3-D printing in the scale world - just in terms of having an adequately detailed model? You noted in one of your pictures that there was a missing mounting bolt on the wheel lathe - which I'd guess in the real world is probably a couple of inches or more. Do you try to render features (into O-scale) that are smaller than an inch? You indicate you can print at a 10 micron resolution (which scaled up from O-scale to 1:1 is ~1/64") - a level of detail that I think even the most ardent rivet-counter would ignore...

Your work is really quite amazing.

SketchUp is like learning to play guitar. You can learn some simple stuff in a couple of weeks. To play like Jimmy Page you're going to need years if even that's possible. My greatest difficulty with SketchUp is on more organic shapes. In its native state it's really an architectural program. It's not a true skinning program like Mesh Mixer and Blender are. It can do that, but you need a raft of plug-ins (many of which I have) and even then, my results are less than satisfactory. The 3D Warehouse is, indeed, a good starting point, but you have to carefully analyze the drawing for those solids and reversed faces. Also, as I've noted before, the folks who draw them don't always follow good SU rules in keeping everything down to the lowest level in groups and components.

As to your question: The usual answer is "that depends". For example, it could very easily print a nice 0'scale bench grinder or vise, plus a raft of hand tools, but the vise handle would have to be two to three times thicker than scale to have it last through the clean up stage. If you didn't have to trim a forest of supports off the model, the chances of fine detail survival is improved, but the supports are a necessary part of the process. I'm working on ways to use diamond burrs to abrade the supports off fine details with some success. Even then, I'm broken off tiny stuff just by picking up the model improperly. And don't drop them on the floor! Experience… ugh!

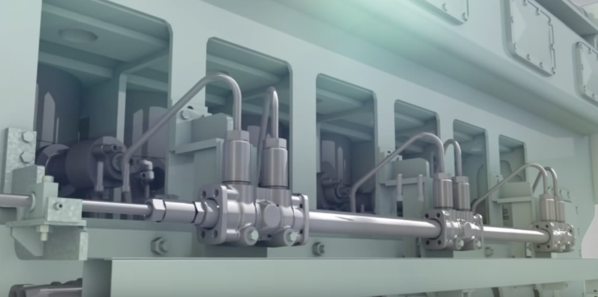

I've just downloaded images of a Fairbanks Morse opposed piston diesel to model. The FM engine has its primary injector pumps on the outside of the engine with an exposed cam shaft driving it. The HP fuel line then feeds through a rectangular opening in the engine's side to the injector nozzle assembly that penetrates into the cylinder's center. I'm sure that the printer would render the injector pumps and shafts very well, and it would attempt to do the fuel line. But they would be really delicate. It would also render the interior of those compartments, but again, it will depend on the support layout as to whether it would be practical. Notice also that the metal thickness of those compartments look only to be 3/8" to 1/2" in real world. That would be very thin printed. I would have to thicken them up a bit to ensure they would be viable. I'm thinking that I should write an instruction set on using SketchUp for 3D printing.

Unlike the EMD, I did find a good elevation drawing of this engine and a listing of the critical dimensions. It should be an easier thing to model. That is except for that induction system with those massive turbo chargers. This engine has a big Roots style blower on the one end and turbos on the other. Serious efficiency. I think they're still manufacturing these engines for power generation. They were more successful in marine and stationary use than in locomotives. They were not as easy to repair on the road.

I don't have any FM powered engines. I guess I'll need to get myself a Trainmaster...

Keep asking questions and I'll keep answering.

Attachments

On Saturday I bought 4 LED stoplight fixtures since they finally went on sale. I needed 8. I went back today and bought four more. The sign over the pile said $19.99. Four would come to about $80. When I got to check out, the clerk told me $135 (including tax). "Wait a minute!" "They're $19.99! She said, "The sale was over Saturday." I asked if there was anything that could be done. And then I told her that the signage disagreed with that. She sent the packer down the "Impulse Aisle" and she took a cell phone pic of the sign which clearly said, $19.99. She called the manager over and I got them for the listed price.

I installed all the lights today. It took a bit of finesse to keep from dropping the old lights onto existing structures especially the refinery. I did all the changes without damaging anything. I also reoriented some of them to better light some of the areas. Originally, I installed the lights before there was a layout underneath them. Now they're in places where the lights need to be. I have exactly one fixture left that's old-school florescent. It's over the back shop work area. When they go on sale again, I may buy one more. For 20 bucks you can't go wrong.

The light is probably 50% brighter and warmer. Makes for much better viewing and picture taking. 50% more light and half the power usage. No humming and instant on. I'm glad I did it in one go and stopped dribbling it out. I had LEDs over the town for over a year.

Attachments

That was good deal, but, I have 4 twin tube fluorescent shop lights over my layout and another over my bench. The local WallyMart is selling a 2 pack of LED replacement bulbs ( fit T8 and T12) for $8.88 a pack. Total cost $44.40!

I had used the replacement bulbs in a 4-tube fixture in our master closet and they worked perfectly. So I bought 10 of them to begin replacing the lights over the layout. They were terrible! My ballasts must not have been compatible. I thought they were. I installed six tubes in three fixtures and only one tube ended up working. I took them back to Lowe's. The fluorescents were really bumming me out. They were dull and made bad pictures. It was time to change.

Looks great!

In general, you are best off getting the "non-compatible" LED fluorescent replacements (the ones for which you have to remove the ballasts). You should also get the kind that use the original "tombstone" connectors on each end, not the ones that feed both at one end. Less hassle in the long run and better energy efficiency.

Buy them from Amazon. They have the less-common lengths, too.

I really didn't want to screw with ballast removal since it meant pulling all the fixtures down from the ceiling. As it is I had to do that anyway with the new fixtures. They're working really great. They're instant on and nothing is buzzing or humming.

I bit the bullet and pulled up the track covers in the engine house. I needed to be able to power engines into and out of the building or the whole deal would be useless. I was certain that the power interruption was due to the filler pieces sticking up beyond the center rail and forcing the rollers out of contact. They came up relatively easily since hot glue isn't the be all and end all of glues. I removed the lumps on the ties, and right now I'm leaving the ties and the little bit of ballast under them intact. I may remove all that ballast and paint the ties to look like concrete ones… or I may not. I did get trains running in and out as they should. I had to clean the rollers and wheels on the Q2 since they were simply not conductive from lack of use. And then my little SW1 Cow and Calf switcher starting running very badly. Badly like one motor was running and the other was stalled.

I took the engine into the shop and quickly diagnosed that something got into the gear train. After disassembling the truck sides and dropping the truck, I found some stones trapped in the main gear. After removal every thing worked as it should. Engines are now in the engine house… as it should be. Next up… doing the landscaping.

On the S-38. I'm waiting for the new solder to arrive. I got my metal supply to make the missing struts. I used the idle time to turn some new prop spinners and designed and grew a fixture that will hold the main struts in proper alignment at their tops while I solder their bottoms to the main wing. I was going to make it out of wood, and then realized that I could grow one.

I was able to use my ball-turning attachment for the Taig lathe to make the nice spherical nose. The models props are wood that were painted to look like metal. I'm in the process of using sanding sealer to remove more of the rough grain before priming them for repaint.

I took the corel draw plans and built the jig on top of it.

My first version is too wide and I found that the slots are only half right. It turns out that the brass struts are 7/32", but the steel ones are 1/4". I now know what the steel struts were. They're key stock because I found steel of the exact same cross-section in my metal supply drawer. I bought this metal at the time I bought the lathe (about 40 years ago). So I went back and adjusted the width (more narrow) and opened up the more acute angled strut (the steel one) to accommodate this. The circular notches are for the twisted floral wire that will hold everything secure.

This is the wrong one. The new one is being grown as I write this. It's amazingly strong.

Attachments

Today was an odds and ends day. I'm still working through the engine house punch list items. Today it was build the caged access ladder to the gantry hoist. I had some chunks of the Plastruct ladder and cage set, but not enough of either to make a single-piece ladder. I measured the height to the gantry rail and spliced two ladder pieces end-to-end to make the correct length. I then glue on the cage. It was the right height, but the top end didn't have a ring. It was just a bunch of slats sticking up in the air. I cut a ring off the remaining chunk of cage and first solvent cemented and then CA'd it to the assembly. I primed it white Tamiya primer (a good color under yellow) and then air brushed it with Tamiya flat yellow. I stuck it into the engine house with the contact cement strips I've been using. You step directly from the ladder to the gantry which is why its facing in that direction. You'll also notice that the 567 looks different.

I decided to see how the engine looked with the detail painting. This wasn't a perfect engine. The next one I'm building today is more perfect, but it can still get better.

First I went to work on the cylinder head details. That painting alone added some significant realism to this already realistic model. Painting consisted of using A-K Interactive black wash, then Tamiya gloss Smoke to give that oily look. I followed this up with Tamiya gloss black for all the valve gear and the power pack clamps. Next I used the Molotow chrome pen to pick out selected bolt heads and the injector racks, and finally used Tamiya Black Panel Line Accent around the cylinder pots.

After the cylinder area I went over the whole model with panel accent and wiped off with Q-Tip dampened with some low odor mineral spirits. I then brush painted the mufflers with Vallejo Dark Flesh (a great rust base color). I filled the exhaust stacks with black accent and then used brown and black weathering powders on the mufflers.

If anyone would like one of these engines for dioramas or flat car loads, let me know.

I took some photos inside the engine house using the cell phone on the "selfie" setting to make it easier to put it into the front door and see the view screen. If it wasn't for the huge flanges, the swinging pilots and that 3rd rail, it could really fool somebody. For some reason the back row of LEDs are not getting enough voltage. The outside light is. It may be draining the circuit in some funny way. I may have to re-wire that light into it's own feed.

It really shows just how huge the Q2 is. It's one of my favorite engines of all times partially based on seeing a Max Gray engine in a long-gone hobby shop in downtown Philly, Les Meyers. I saw this engine in their window when I was probably 8 or 9 years old and it burned itself into my brain.

I put together another 567 of the last parts that I printed. I had two back ends. One with the corrected flywheel where the generator fits better, and an older one missing the oil lines. So of course I had to spend a half hour adding back 0.020" phosphor bronze lines. It didn't take so to drill and bend. It took time to keep finding the **** things that I kept dropping on the floor.

Then I found the correct one… so it was all for naught. I built the engine and primed it. It's now drying.

S-38: I got a successful 3D part completed for the strut jig. It will work nicely. The width and the slots are dead on.

I also painted the props the bronze color that the rest of the plane will be. I put these aside until the end of the build. I was a shame to cover up those pretty spinners, but the model is to appear monochromatic.

Attachments

Looks great, Myles. The engine looks great. The photo of the locomotives in the shop looks very realistic. The S-38props look like brass. Impressive all around.

Myles, I will go back and review your wonderful thread and give you a review. It’s been a crazy busy summer with so many house chores to do keeping me away from the hobby. The visit to your home and wonderful layout was a tremendous highlight for our travel activities. Thank you for your “Continuing Saga”, it’s great reading, and great Modeling. Your Tennessee and Kentucky friends....

Myles, The inside views of the engine house look great!! Very realistic as we have come to expect!

Myles, everything looks so amazing. I want to say it may have been two weeks or so ago, I showed our machinist one of the equipment pics(think the lathe). He said, "yes, I've worked on that one." My reply was, "well maybe, but not one this small." He remarked on how excellent that(and the other pics I showed him) looked.

Very nice following the build!

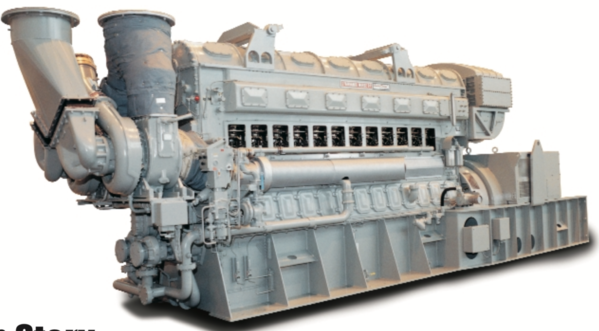

A local fellow had asked for, I printed and he purchased an HO version of the EMD 567 and now he asked if I could do a Fairbanks Morse Opposed Piston Engine. I'm about 3/4 through the design work and I'll again produce O and HO versions. I'm using the same alternator as I did with the 567. No point in reinventing the wheel. Loco FMs are simpler than stationary or marine versions. Most of the latter have some pretty elaborate turbo-chargers on the end opposite the scavenge blower, that large structure on the near end. Like EMDs, FMs were essentially 2-strokes, but in FMs case there were no valves are all and no cylinder head. The combustion chamber was virtual, being the confined space when the two opposing pistons closed on one another. They didn't touch, but created a small compression space where the dual injectors would spray fuel oil. EMDs were easier to service and were thus more favored by railroads. FMs were very efficient and high power and are still being manufactured for stationary and marine use.

To pull the cylinders in the FM you had to remove all those top covers and then pull the upper crankshaft. This was impossible to do effectively in the field. It was easier to just pull the entire engine and take to a service center. EMDs on the other hand, could have a power pack removed in a half hour. The power pack consisted of the individual head, the cylinder liner, piston and connecting rod. There was provision to mount a hand-operated crane right on the cylinder head so two guys could remove and replace the power pack in the field.

FMs are a uniflow engine. There were two sets of ports cut into the cylinder liner. The upper ports opened a bit later than the lower ones and closed later. Upper was intake air and lower was exhaust. As the bottom piston uncovered the exhaust it would flow to the exhaust box surrounding the cylinder under it's own pressure. Then the upper piston uncovered the top ports allowing incoming air to flood the cylinder. It was under some pressure from the scavenge blower and the pushed the remaining exhaust out. All gas flow was in the same direction from top to bottom, thus the term, "uniflow". It's very simple. The complexity was the bevel gears and shaftings to tie and synchronize the upper crank's motion with the lower one. Power take off came from the lower crank. Because all the cylinders were in line, the engines were rather skinny.

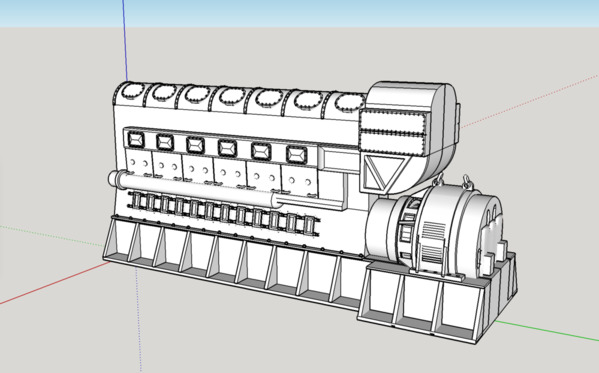

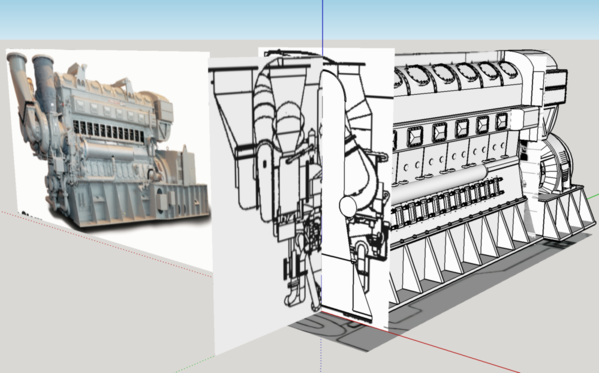

This next image shows how I arranged and scaled the drawings to rough out the shape. In addition to top, front and side views, there is also a good section drawing at the back that gave me accurate shaping of the various bumps and channels. In stationary and marine use, the injectors and associated camshafts were exposed as I showed in an earlier post. In loco use they were covered with removable hatches which I decided to draw. It will be easier on the printing end. I may steal my water pumps from the EMD so I don't have to draw them again. They're pretty generic. The front view in this image is a stationary engine and has all those turbos. There are two exhaust headers, one of each side so there are two sets of turbo chargers too. The loco version just has two big headers leading to two mufflers.

S-38: With the new solder and flux plus a lot more BTUs, I'm in the full soldering mode. I used my fixture and secured the main struts to the main wing. I re-soldered the nacelle that was not very good, and cut and started fitting the engine support struts that were completely missing. I'm using 1/8" square brass for these missing struts and I've also replaced the steel struts with brass. I didn't like how the steel was soldering. It wasn't. The fixture cracked when putting on the second set, but it had done its job and was no longer needed.

With the main struts prepared, and the engine struts soon to be installed, I'll be ready to mate the lower wing and fuselage to the upper wing. I will turning the whole deal over to do that step. I will continue cleaning the solder joints up after I finish this phase.

The missing engine struts were pinned to the nacelles and I'm going to do this too. I opened the existing holes and drilled new holes next to broken pins that had remained in their holes. I soldered the pins (3/64" brass) to the shaped brass and temporarily fixed them in place. I needed to do this so I could get the measurement for the third diagonal brace that goes between these two. There's another V-shaped set of struts that go from the engines' inner side to the fuselage top. Those will have to wait until the main parts are joined.

Things are moving quickly. I'll do work on this tomorrow, but then we're heading back East for a wedding this weekend and will be back at work on this next mid-week.