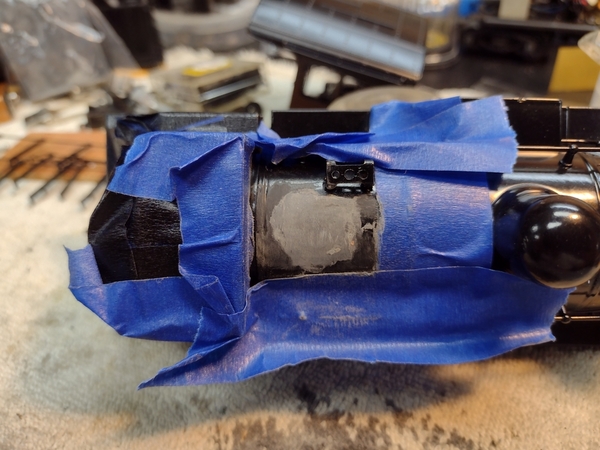

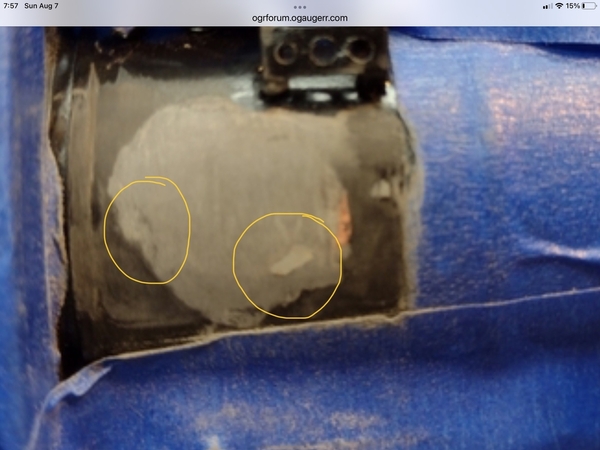

Ok, let’s look at the blocking process,…..I’ve fashioned some blocks from scrap hardwoods that I had lying around….they’re perfect for this kind of work. It doesn’t matter the material, it matters that it’s a.hard, & b. Square …beings I mudded this thing up, I started with 600, then switch to 800….but I wanted to dig into it so you guys see the common mistakes, and can learn to read your own work …..so let’s the examine our work area from left to right, and define what’s going on, and how to know what’s what,….so when we look at the far left thin red circled area, we see what looks like layers,….so we’re too far over in the blocking process,….those islands can get worse, and show up in your finish,….it’s faint enough right now to fill in with primer, and re-level, so don’t go any further when you get islands forming ….if you do, use different angles to look at it and see if your islands will turn into puddles…..so now in the middle area, you see I’ve red lined my lows ….these lines are over low spots in the filler,….we need to jump right over to the blue circled area, and see we’ve already gotten down to bare metal, so we can’t go any further or you’ll make a new divot trying to chase out the low spots outlined with the red lines…..so the moral of the story, and again, I’ve done this on purpose, it needs to be wiped again with filler,….when the spot is correct, we should see the filler blending in with the surrounding black,…since we’re working ON TOP of existing paint,…..so we’re not done,…..and George, notice how I’ve pulled the tape away from those precious details we don’t want to disturb,…I’ve worked the HE-double toothpicks out of this area already, and those hinge details are still perfect!….that’s the idea of tape, tape, and retape !…😁

Pat