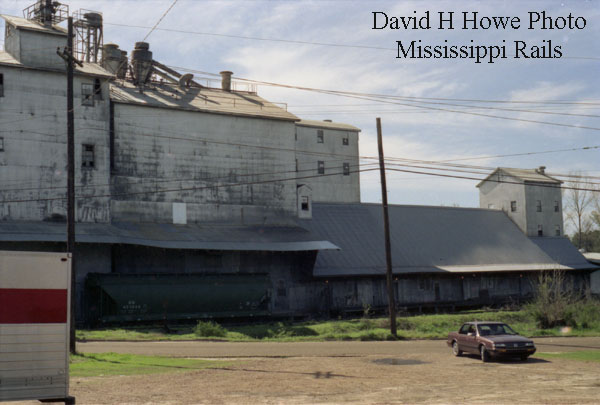

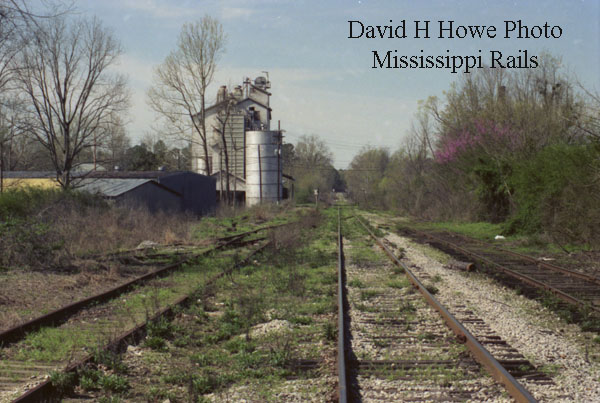

I built this to go in a corner. I wanted it to look massive and fit against the background. I am planning to cover it with corrugated aluminum. It took about 2 1/2 hours to build this.

Malcolm

New pics of corrugated siding being installed and corrugating tool.

I did this today while smoking a turkey, venison tenderloin and sausage. Smells real good around the smoker.