I didn’t leave any feedback, but I guess I could ask for a partial refund. Was thinking I could use the track as a static display. The coil works in it still, so I could have three sections of derelict track off to the side with an operating boxcar as I have a few of them, and my smoking caboose. The caboose would always smoke, and the kids could press a button to make the boxcar door open. Maybe have a yard light shining on it, and some guys around a camp fire next to it.

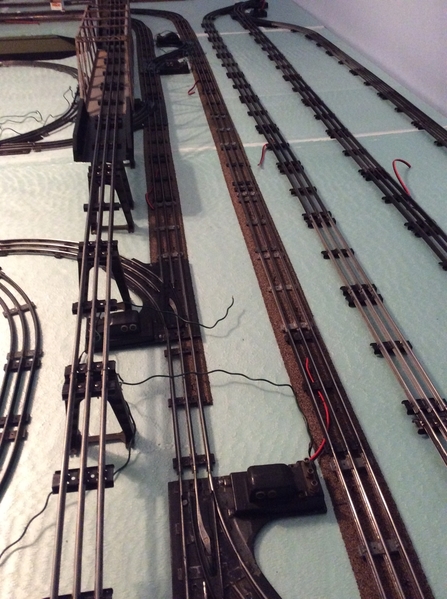

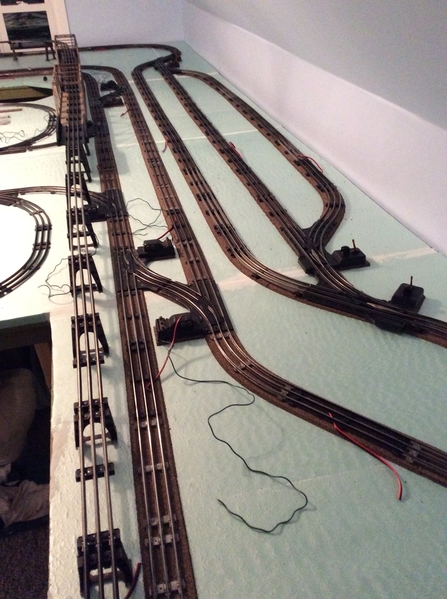

I got my 1121c switch controller wired up, as well as a section of rcs track. Those pile switches are a nightmare.

Got two sections of 6019 track installed and operating tonight also. This one for the saw mill.

Another 6019 for the log loader.

Buttons will be along the side for the kids.

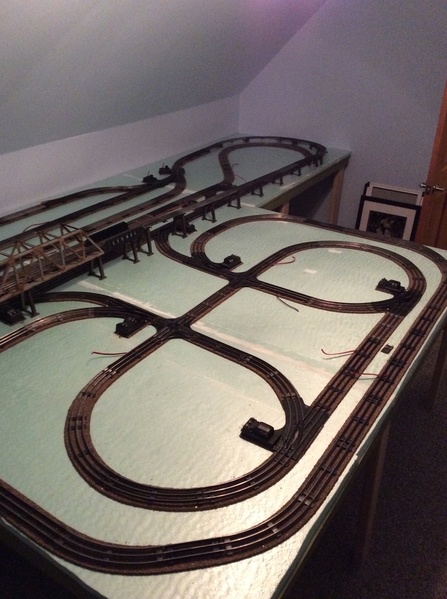

I added extra bents tonight so I can run the GG1 and F3 up here. I’ll spray the grey ones brown before I install them for good.

I almost had enough bents, short only two. I need a G and H size. If anyone has a partial set they would be willing to canabalize for me I would appreciate it

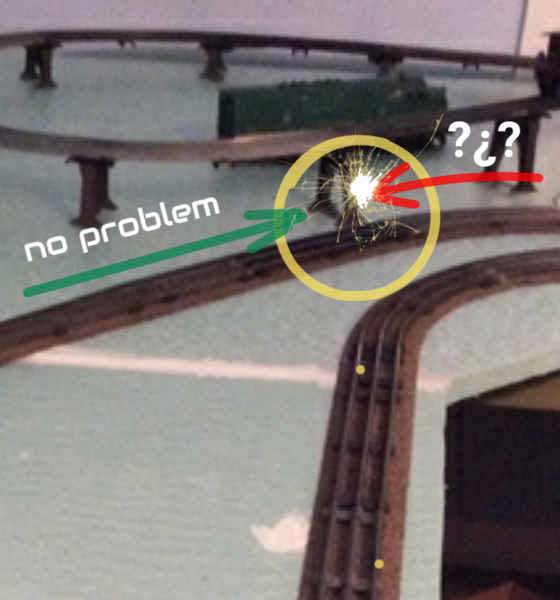

I got the rcs section installed for the o37 line, but my milk car platform will not fit under this section of rcs track. The molded in terminal block hits the side of the platform track channel. Guess I will just dremel out a piece to make room, unless this thing is backwards. Problem is it won’t fit in here the other way I don’t believe.

Tomorrow is more roadbed work, and switch wiring.