Thank you for the help Moonman. That is the kind of brain stimulation I was looking for. Let me try and answer some of the questions.

-The window ac units are for the downstairs bedrooms, not the windows in this room. We are just storing them here for the moment. There will be no ac in these windows.

-We usually do not open these windows. Wasps tend to come in when we do. Thinking we can keep the benchwork wider in this spot.

-The heater is not used too much in this area, helps keep the fuel oil bill down. Will be using a plug in heater to just heat this room. Summers I will not be using the trains much, so no need for cooling.

-I will check the electrical out today. That was something I hadn’t thought of. Will report back with findings.

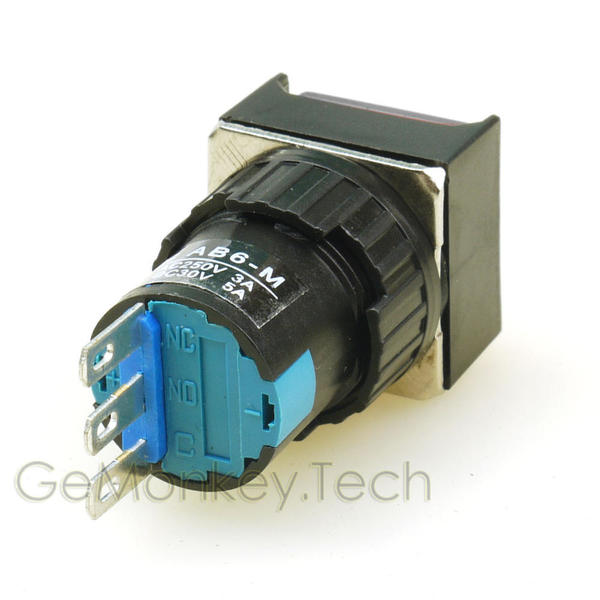

-The only lighting in this area at the moment is on the ceiling fan in the middle of the room. What would you recommend for lighting on a layout? Something on a dimmer switch I assume? A fan would be a bad idea because it would blow around scenic grass and foam?

-Will head out today and find some Tibetan blue. I need to paint the whole room because it needs it. It hasn’t seen paint in decades. Also need to finish some baseboard trim and paint before I start. Hoping to get that going today.

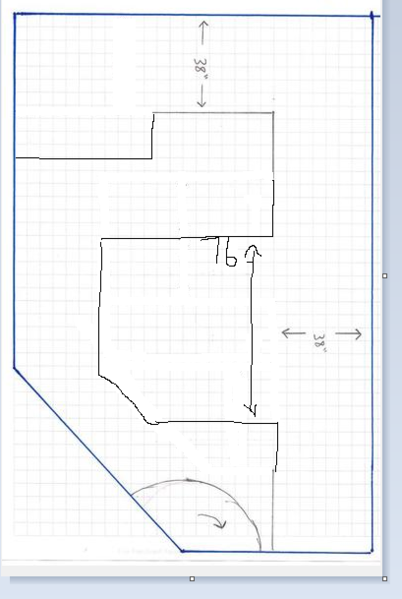

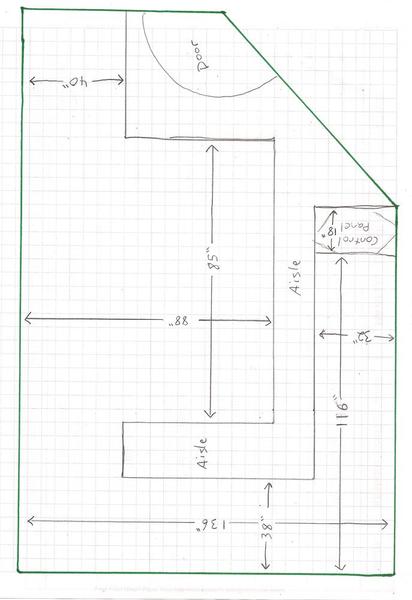

-Some updated measurements:

The shorter long wall is 135”

The longer long wall is 202”

The window wall is 137”

The door section of wall is 61” from door frame to corner of shorter long wall.

The last section of wall is from door frame to corner of longer long wall. This section of wall is not angled, it is flat and perpendicular to the window wall. This piece is 70”

The only section that is angled is the wall with the door in it.

Height of the knee wall is 44”

Height to bottom of window sash is 34”

Thank you again for all the help.

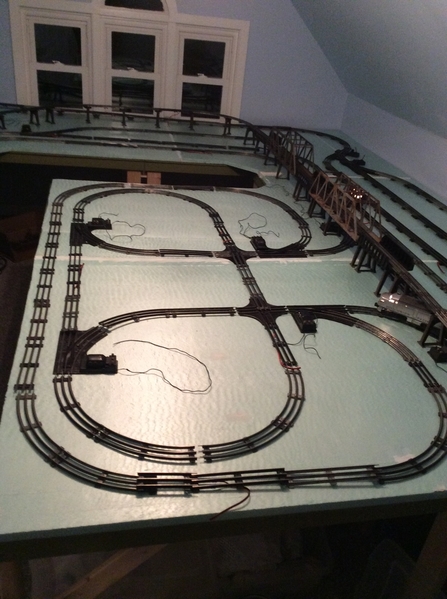

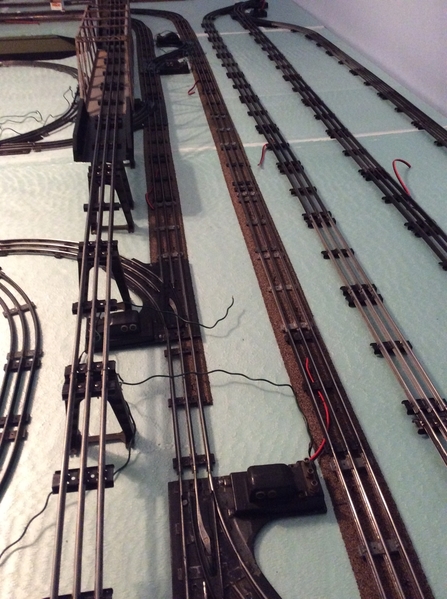

Just a quick back story. All of my track, and most of my trains came to me from my Father. They were his and my Uncles when they were kids in the 50’s. My Grandfather who I was very close with bought most of these train sets for them and spent hours playing with them with the kids. My Grandfather, and Uncle have both since passed. My Dad is 71, and I would like him to see his trains running once again before his health deteriorates. I now have children of my own 4 and 7, and would like to pass on this Lionel tradition.

Thank you again for your help. I’m currently cleaning all of their old track and will get a track count for you. I figured I could always buy more if I ran out. Thanks again