We've been dealing with those tough to open snap lids on Atlas scale coupler pockets and less than reliable coupler performance for many years (in my case since 1971!). My preference is to replace Atlas couplers with rock solid Kadees. But as most know the mounting holes used by Kadee and Atlas have slightly different spacing and setback from the end sill. While some have worked around the spacing issue, mounting Kadee pockets using the existing Atlas holes causes the pocket to noticeably stick out beyond the end sill taking away from the prototypical appearance of the car. IMO the best conversion appearance wise is to use an adapter plate, and/or drill new holes and add spacers to compensate for differences in pocket thickness - but that takes a lot of work and careful handling to do the job right.

On several occasions I've talked with people at Kadee suggesting they offer a conversion coupler set specially fitted for Atlas O scale rolling stock. Typically they find the idea interesting - but so far no product announcement. I suspect our niche market may be too small to develop, produce, and sell the product with a reasonable return on investment.

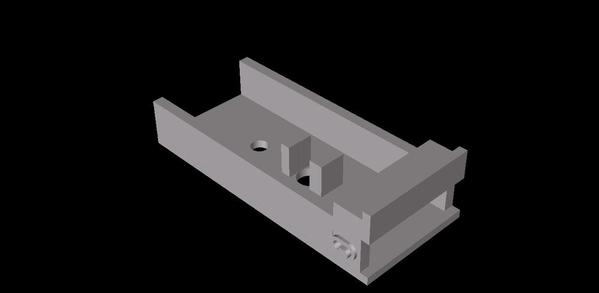

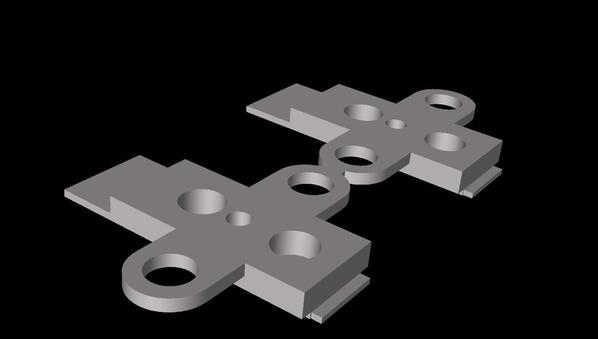

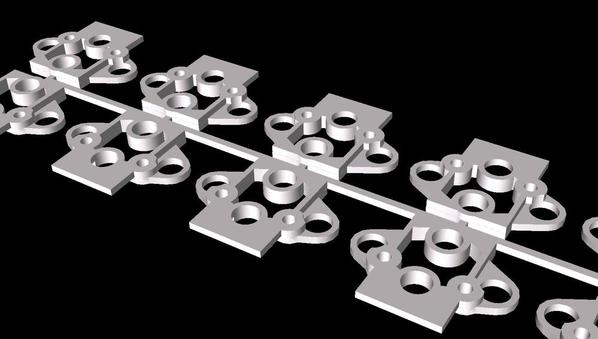

After seeing the creative application of 3D printing by guys on this forum, I'd like to hear if others think it would be possible to design and 3D print a Kadee conversion pocket tailored for Atlas cars. For consideration I would propose the following attributes:

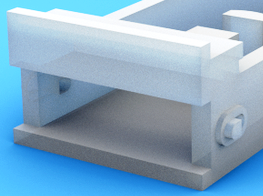

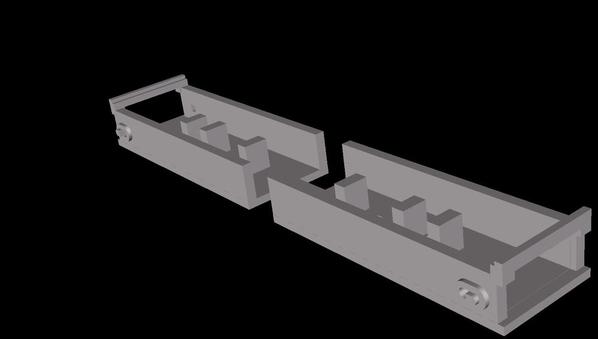

- pocket mounted to the Atlas underframe reusing existing tapped holes for 2mm flat head screws

- pocket upper surface thickness matching the "thick" Atlas dimension to retain OEM car body and coupler height

- front edge of the pocket flush with the end sill (possibly with some prototype draft gearbox details missing on Kadee pockets)

- screw on coupler pocket lid

- Compatible with either Kadee 805 or the new 745 coupler shanks

Comments??