Bottom line up front: if you want DCC, just install a big decoder and leave the motor alone.

I'm guessing that the gear ratio is at least 24:1 (it would be useful to know for sure.) A Pittman 9412 is a slow-turning motor, probably slower than the CLW motor that's in there now, so you're going to lose some top speed. That may or may not be important to you. The "1" in 9412 indicates that this particular Pittman doesn't have rare-earth magnets (which were probably introduced after it was made.) You didn't mention if your Pittman has ball-bearings. If the CLW is already a 7-pole motor, the Pittman may not be much smoother or more powerful, so there's no performance advantage in the swap.

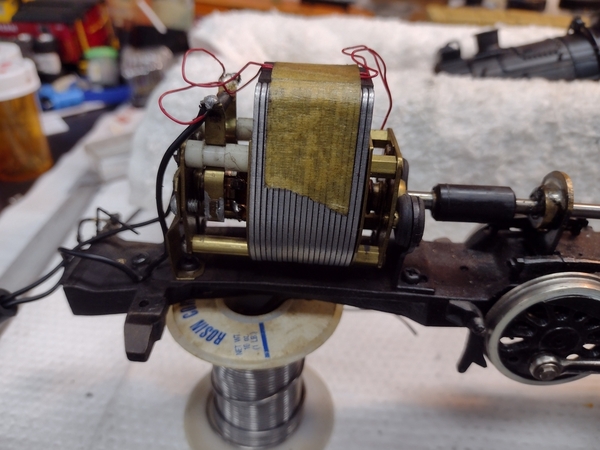

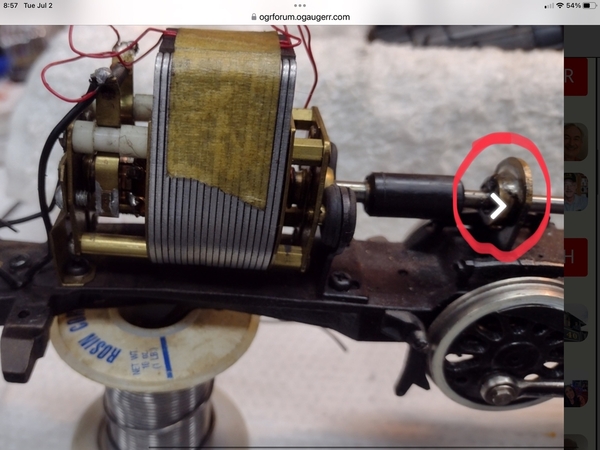

A swap also introduces issues with form factor and driveline angle. An open frame motor is asymmetrical. Because there are no magnets nor motor case at the bottom gap between the poles, the armature shaft can lay down very close to the chassis and line up with that bearing support Pat pointed out. If you install a can motor (*unless it's a gearhead motor) the output shaft is in the center and it's going to sit higher, which will mess with the alignment. The gearbox itself will rotate to line up, but you'll have to make a new bearing support or a custom torque brace, etc.

Scott thanks for posting link to the video, but I don't agree with your logic 100%. When a loco is starting out, even a heavy train on a grade with the slack stretched, it'll definitely be pulling some amps, but not "stall current" the way it's defined in the video. Remember, Soundtraxx wants high sales revenue and zero customer claims of failed decoders. So it's in their interest to sell you a bigger decoder than you can probably get away with. In the video, the guy presses the loco into the track and forces the wheels to stop turning (it hurts me to watch this!) In actual use that should NEVER happen! A properly-designed loco should spin its wheels when it's overloaded. This is a function of many variables: weight on drivers, gear ratio, motor torque, driver tire material, track cleanliness, etc. USH are really well-engineered. But if a previous owner packed extra lead in there, I would personally remove a little until you're confident that the wheels will spin when overloaded.

For decoder selection purposes, I would measure max current like this: Hold the tender coupler or the boiler front and let the loco push against your hand. SLOWLY increase voltage until the wheels alternately slip and grab. Check your amps, and THAT's the max current that you're likely to see in use. Your CLW is a permanent magnet motor, not a wound field "universal" motor, so my guess is that the DC current draw will still be well within range for DCC. Plenty of space in the tender, so worst case stepping up to the next-larger size decoder might cost a few bucks more. Think of it as cheap insurance.

If you had a ball-bearing Pittman 9434, or if you come back and tell me that the loco is geared at 16:1, then I would advocate for a Pittman swap. But I'm guessing that your "Big Emma" is a pretty good performer already, and I don't see any reason that you can't convert her to DCC in situ. My $.02.