I'm getting ready to LED my R40 Slant subway set. I did my R32 set already and while it looks great, there's a few issues I hope to fix. The first and biggest is running them on DC. Currently, I just run my LEDs on AC while it works well, they do give off (at least IMO) a bit more heat then they should, on two of the four cars, the shells are developing little indents due to the heat. No fun. I do NOT want that to happen to my R40. I'd like to keep the flickering on the cars since the real cars flicker over switches and the like. I'd use @gunrunnerjohn's lighting board since I run DCS but would there be a way to remove the capacitor (or install a smaller one) so the flicker will stay? The next issue is when I did the end lights in the powered car, when stopped, they do dim a very slight bit, not enough that you could really tell but if you look at it directly after it stops, you can see the change. Almost like the car has rule 17 lighting. I run the set at 18v but if I turn the voltage down a hair (to 17v) that goes away. Thanks for the help.

Replies sorted oldest to newest

There have been posted some DIY lighting boards that use thru-hole design, you could make a few of those and adjust the the cap value to anything you like.

Are your LED strips stuck directly onto the shell? I was looking at doing this for mine, but planned to mount them loosely, retained by the bracket that held the original incandescent lights. I believe the 600-LED strips (each group of three has smaller spacing) line up rather well with the gaps in the bracket.

---PCJ

I've mounted LED's directly to the shells of countless passenger cars, 50-60 of mine, and more of customers. Running them at reasonable intensity, I've never felt them even get warm, much less how enough to deform the shell! Unless you bought the high-power LED strips, I don't know how you get them hot enough to actually melt the plastic! Here's an 18" MTH Premier car light with 25ma total power to the LED strip. There is zero danger of anything melting here. How bright are those LEDs to melt the shell???

Attachments

@RailRide posted:Are your LED strips stuck directly onto the shell? I was looking at doing this for mine, but planned to mount them loosely, retained by the bracket that held the original incandescent lights. I believe the 600-LED strips (each group of three has smaller spacing) line up rather well with the gaps in the bracket.

---PCJ

Yes, I mount them direct to the shell.

@gunrunnerjohn posted:I've mounted LED's directly to the shells of countless passenger cars, 50-60 of mine, and more of customers. Running them at reasonable intensity, I've never felt them even get warm, much less how enough to deform the shell! Unless you bought the high-power LED strips, I don't know how you get them hot enough to actually melt the plastic! Here's an 18" MTH Premier car light with 25ma total power to the LED strip. There is zero danger of anything melting here. How bright are those LEDs to melt the shell???

I'm not sure how bright they are. They look great but they do get very warm. I used a different brand of strip (I typically use the LE brand from Amazon) on the R32 set. Obviously, the damage is already done but if I replaced the strip with the LE brand, would they not get as hot?

You have to control the current to the LEDs for consistent results. My guess is if they're getting as hot as you say, they're running at way more than the maximum rating of common LED strips. Without knowing specifically what you have, it's hard to say what they're rated power is.

FWIW, I have really bright LEDs on my workbench, they are much higher current than the common 300 LED 5 meter strips, and they do get fairly warm in operation. Since they're stuck to a wood shelf, there's little danger of anything melting. However, I suspect those might deform a plastic shell if they were stuck directly to it.

@gunrunnerjohn posted:You have to control the current to the LEDs for consistent results. My guess is if they're getting as hot as you say, they're running at way more than the maximum rating of common LED strips. Without knowing specifically what you have, it's hard to say what they're rated power is.

FWIW, I have really bright LEDs on my workbench, they are much higher current than the common 300 LED 5 meter strips, and they do get fairly warm in operation. Since they're stuck to a wood shelf, there's little danger of anything melting. However, I suspect those might deform a plastic shell if they were stuck directly to it.

True. I think I'll go in and pull them and replace with the LE brand, they definitely don't get as hot. Heres some photos of the cars. You can see the indents, the rear car is the worst. These are the LEDs I will use.

Attachments

Well, whatever those are, they're clearly pushing more than 20ma!

The strips you linked look to be standard 2835 sized 300 LED strips, the maximum current through each 3-LED group would be 20ma at 12VDC. Unless you pushed those way over their ratings, they will not get so hot as to melt the shell of a plastic car.

@Trainlover9943 posted:...The next issue is when I did the end lights in the powered car, when stopped, they do dim a very slight bit, not enough that you could really tell but if you look at it directly after it stops, you can see the change. Almost like the car has rule 17 lighting. I run the set at 18v but if I turn the voltage down a hair (to 17v) that goes away.

1. When you say your present 12V DC LED strips are AC powered, they are directly connected to track-voltage (center-rail roller, outer-rail wheels)?

2. What LEDs did you use for the end lights? In your photo above, if these are the powered end cars, it appears you have green, red, and white lights. Since you say you run DCS presumably these are MTH PS2 and you replaced bulbs with LEDs? That is, PS3 cars are already LED. Just trying to understand what you changed for the end of car lighting and where the power comes from (e.g., a light output on the PS2 harness).

Attachments

@stan2004 posted:1. When you say your present 12V DC LED strips are AC powered, they are directly connected to track-voltage (center-rail roller, outer-rail wheels)?

2. What LEDs did you use for the end lights? In your photo above, if these are the powered end cars, it appears you have green, red, and white lights. Since you say you run DCS presumably these are MTH PS2 and you replaced bulbs with LEDs? That is, PS3 cars are already LED. Just trying to understand what you changed for the end of car lighting and where the power comes from (e.g., a light output on the PS2 harness).

1. Yes.

2. I used standard 3MM white LEDs with 330ohm resistors. Yes, all I did was replaced the bulbs with the LEDs. The R32 (the set on the left and the one I converted, I haven't touched the R40 yet) is a PS2 set.

330 ohm resistors? That's not standard for the 5 meter reels with 300 of the 2835 LED chips, they use a 150 ohm resistor! If there's a 330 ohm resistor for each three LED group, I can't imagine it generating enough heat to melt plastic!

@gunrunnerjohn posted:330 ohm resistors? That's not standard for the 5 meter reels with 300 of the 2835 LED chips, they use a 150 ohm resistor! If there's a 330 ohm resistor for each three LED group, I can't imagine it generating enough heat to melt plastic!

330 ohm resistors for the powered car end lights. The non powered cars just used LED strips.

I pulled all of the strips from the cars (threw them and the rest of the strip away) I replaced them with the LE brand LEDs. Definitely a difference in brightness.

Attachments

I'm guessing whatever you had in there were the high current models that would be generating a lot more heat.

FWIW, $10 is pretty expensive for standard white LED reels. ![]()

@gunrunnerjohn posted:I'm guessing whatever you had in there were the high current models that would be generating a lot more heat.

FWIW, $10 is pretty expensive for standard white LED reels.

How much is a typical white LED reel?

Do a search on eBay, plenty of the 2835 300 LED 5 meter strips are in the $2.50-$4.00 range. I don't recall ever paying more than $5.00 for a 5 meter roll of them.

@gunrunnerjohn posted:Do a search on eBay, plenty of the 2835 300 LED 5 meter strips are in the $2.50-$4.00 range. I don't recall ever paying more than $5.00 for a 5 meter roll of them.

When I'm ready to buy more, I'll check them out. You have a wiring diagram or parts list for the LED boards or could I just buy yours and replace the capacitor with something smaller?

@Trainlover9943 posted:... The next issue is when I did the end lights in the powered car, when stopped, they do dim a very slight bit, not enough that you could really tell but if you look at it directly after it stops, you can see the change. Almost like the car has rule 17 lighting. I run the set at 18v but if I turn the voltage down a hair (to 17v) that goes away...

@Trainlover9943 posted:...

2. I used standard 3MM white LEDs with 330ohm resistors. Yes, all I did was replaced the bulbs with the LEDs.

If you simply replaced a PS2 6V bulbs with a 3mm LED (w/330 Ohm resistor) then the slight drop in brightness can be explained. PS2 boards drive the light outputs to maintain constant brightness in a lamp (vs. constant brightness in an LED). It gets techno-nerdy regarding the difference between RMS and Average. What happens is when the engine stops, the average voltage applied to a PS2 light output drops slightly even though the RMS stays the same.

As to why the effect appears demoted at ~17V instead of ~18V gets even more arcane so I'm going to leave it at that.

The effect can be seen more dramatically for guys running PS2 conventional where track voltage varies widely. That is, the lamps maintain constant brightness over the conventional voltage range but if you replace a lamp with an LED (plus resistor), you will see a change in brightness. It's not a dramatic effect but is there nonetheless.

If it's critical to maintain constant brightness in your PS2 LED+resistor light output, it would involve adding maybe 3 or 4 components to regulate the light output to maintain a constant average voltage rather than a constant RMS voltage. It's not that it would be expensive (maybe $1 per light output) but I think somewhat tedious...in my opinion of course!

@stan2004 posted:If you simply replaced a PS2 6V bulbs with a 3mm LED (w/330 Ohm resistor) then the slight drop in brightness can be explained. PS2 boards drive the light outputs to maintain constant brightness in a lamp (vs. constant brightness in an LED). It gets techno-nerdy regarding the difference between RMS and Average. What happens is when the engine stops, the average voltage applied to a PS2 light output drops slightly even though the RMS stays the same.

As to why the effect appears demoted at ~17V instead of ~18V gets even more arcane so I'm going to leave it at that.

The effect can be seen more dramatically for guys running PS2 conventional where track voltage varies widely. That is, the lamps maintain constant brightness over the conventional voltage range but if you replace a lamp with an LED (plus resistor), you will see a change in brightness. It's not a dramatic effect but is there nonetheless.

If it's critical to maintain constant brightness in your PS2 LED+resistor light output, it would involve adding maybe 3 or 4 components to regulate the light output to maintain a constant average voltage rather than a constant RMS voltage. It's not that it would be expensive (maybe $1 per light output) but I think somewhat tedious...in my opinion of course!

Thanks for the explanation. So basically its normal operation with LEDs. It doesn't bother me enough to mess with it anymore. Just have to get the non powered cars LEDs on DC power now.

@Trainlover9943 posted:When I'm ready to buy more, I'll check them out. You have a wiring diagram or parts list for the LED boards or could I just buy yours and replace the capacitor with something smaller?

Project #8 in the Electrical Reference Materials thread.

@gunrunnerjohn posted:Project #8 in the Electrical Reference Materials thread.

Cool. Just opened one of the non powered cars to convert it. I'm not in for a standard conversion with the strips due to the ceiling detail attached to the lighting track. I'll have to use either 3mm LEDs or (probably a better option) push in Cool white LEDs. Where can I find the push in style?

Attachments

I have no idea where you find those. ![]()

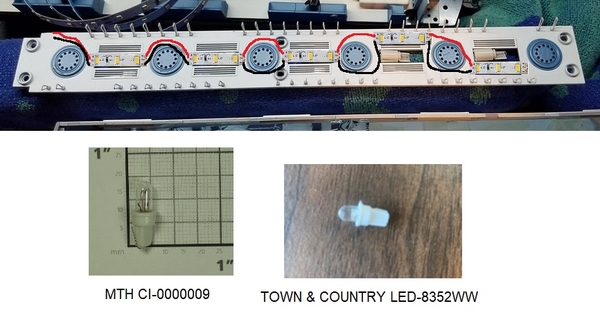

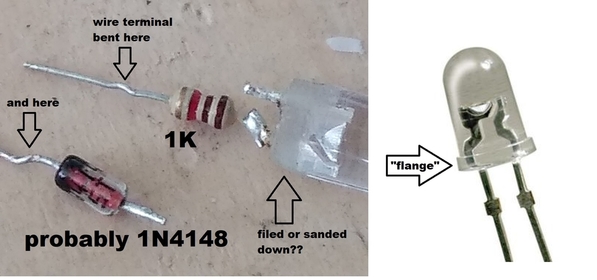

Not sure if your press-in bulbs are the bent-wire-terminal (like traditional Christmas bulb strings) such as MTH CI-0000009, but if so T&C has an LED version (albeit apparently only in WARM WHITE). It was recently discussed in this OGR thread. My guess though is these may not be bright enough based on your photos of your first conversion.

As for an LED strip blocking the air flow from your ceiling fans, how about cutting the strip at a cut-line and then placing 3-LED sections where they fit and then soldering a pair of wires to the copper pads to connect them. Note that the most common strips are 300 LEDs in a 5-meter reel...so each 3-LED section is 5cm (~2 inches). This may be too long. In which case you can buy double-density strips where there are 600 LEDs in a 5-meter reel so each 3-LED section is only 1" long. Seems like a lot of busy-work but appears you are willing/able to work at the component-level.

And if your LEDs are the press-fit style shown above, later in the linked thread the T&C LED is dissected which would show how to roll your own in the LED color of your choice ... for example if you want to replace their Warm White with Cool White or whatever. It would be quite tedious but the component cost would be just pennies per LED and presumably you could re-use the plastic holder from the bulb.

Attachments

Get flangless LED's and no sanding required. ![]()

@stan2004 posted:Not sure if your press-in bulbs are the bent-wire-terminal (like traditional Christmas bulb strings) such as MTH CI-0000009, but if so T&C has an LED version (albeit apparently only in WARM WHITE). It was recently discussed in this OGR thread. My guess though is these may not be bright enough based on your photos of your first conversion.

As for an LED strip blocking the air flow from your ceiling fans, how about cutting the strip at a cut-line and then placing 3-LED sections where they fit and then soldering a pair of wires to the copper pads to connect them. Note that the most common strips are 300 LEDs in a 5-meter reel...so each 3-LED section is 5cm (~2 inches). This may be too long. In which case you can buy double-density strips where there are 600 LEDs in a 5-meter reel so each 3-LED section is only 1" long. Seems like a lot of busy-work but appears you are willing/able to work at the component-level.

And if your LEDs are the press-fit style shown above, later in the linked thread the T&C LED is dissected which would show how to roll your own in the LED color of your choice ... for example if you want to replace their Warm White with Cool White or whatever. It would be quite tedious but the component cost would be just pennies per LED and presumably you could re-use the plastic holder from the bulb.

Cutting the strip where the light bulb was crossed my mind. I might give that a try since I have them.

@stan2004 posted:Not sure if your press-in bulbs are the bent-wire-terminal (like traditional Christmas bulb strings) such as MTH CI-0000009, but if so T&C has an LED version (albeit apparently only in WARM WHITE). It was recently discussed in this OGR thread. My guess though is these may not be bright enough based on your photos of your first conversion.

how about cutting the strip at a cut-line and then placing 3-LED sections where they fit and then soldering a pair of wires to the copper pads to connect them. Note that the most common strips are 300 LEDs in a 5-meter reel...so each 3-LED section is 5cm (~2 inches). This may be too long. In which case you can buy double-density strips where there are 600 LEDs in a 5-meter reel so each 3-LED section is only 1" long.

Are the strips you showed the standard one with the 5cm spacing or the the double density ones? If the double density where can I find them?

My photo was just a cut and paste onto your photo - without regard to scale. Whether eBay, Amazon, or wherever, search "600 LED cool white". These are sometimes called "double-density" strips; and, yes, there are even quad-density LED strips though I don't think you need to go there!

In above example off eBay, you can get 1 Meter of the double-density cool whites for $1.60 with free shipping from Asia. At 120 LEDs/Meter, you could cut 40 individual 3-LED sections 2.5cm (~1 inch) long which ought to be enough to populate your 2nd subway consist. Obviously you will find similar on Amazon or domestically for a bit more coin.

Attachments

@stan2004 posted:My photo was just a cut and paste onto your photo - without regard to scale. Whether eBay, Amazon, or wherever, search "600 LED cool white". These are sometimes called "double-density" strips; and, yes, there are even quad-density LED strips though I don't think you need to go there!

In above example off eBay, you can get 1 Meter of the double-density cool whites for $1.60 with free shipping from Asia. At 120 LEDs/Meter, you could cut 40 individual 3-LED sections 2.5cm (~1 inch) long which ought to be enough to populate your 2nd subway consist. Obviously you will find similar on Amazon or domestically for a bit more coin.

Cool. Thank you!

I found some on Amazon but there pretty expensive. https://www.amazon.com/dp/B00J..._apa_i_uEpEFb4HJG7H3

@stan2004 posted:

I'm sure I can find a use for the rest of the reel. I'll go in for that one since it's a better cost.

I got my LED strip today. They will fit perfectly. Just one issue, how to power them? Any thoughts?

Attachments

Attachments

@gunrunnerjohn posted:

I could use that and I probably will, I'll just pull the capacitor so they still flicker. However, I need to find a way to connect the LEDs to the metal strip on the car, I don't know how to do that without damaging anything. Under the LEDs, which I can get a better picture of, there's the metal strip which was for the push in bulb. Could I just cut it how I need to get it to line up and then solder the strip to it. The other issue becomes securing the LEDs to the board, there no real way to do that.

Why would you pull the capacitor?

In the times I've used the metal strip, I just solder to it.

FWIW, I normally pull that whole lighting strip out of the car and put a full row of LED's down the ceiling of the car. With the regulator board, you can adjust the intensity to anything you like and you have nice even lighting throughout the car. If there are any "nubs" that hold the lighting fixture, I just whack them off. Here's one of many examples, on this one the regulator board is stuck to the ceiling, it's well above the window line and not visible through the windows. This is a slightly fancier job where I had side markers and a rear taillight on an observation car, those were wired individually. After I'm all done the loose wires you see are secured with hot glue.

Attachments

@gunrunnerjohn posted:Why would you pull the capacitor?

In the times I've used the metal strip, I just solder to it.

FWIW, I normally pull that whole lighting strip out of the car and put a full row of LED's down the ceiling of the car. With the regulator board, you can adjust the intensity to anything you like and you have nice even lighting throughout the car. If there are any "nubs" that hold the lighting fixture, I just whack them off. Here's one of many examples, on this one the regulator board is stuck to the ceiling, it's well above the window line and not visible through the windows. This is a slightly fancier job where I had side markers and a rear taillight on an observation car, those were wired individually. After I'm all done the loose wires you see are secured with hot glue.

I'd pull the capacitor because I want them to flicker over switches and the like since its a subway. The only problem with removing the lighting strip is I can't, the ceiling fan and strap detail is attached to it. I have to keep it.

Well, if you really want flicker, I don't think this is the module for you. The regulator requires filtered dc to operate, it needs a capacitor. It could be a smaller one, but that probably won't really achieve the result you're looking for.

BTW, you're the first, most people buy the module specifically because they want to eliminate the flicker! That's also why I originally designed it for my use!

@gunrunnerjohn posted:Well, if you really want flicker, I don't think this is the module for you. The regulator requires filtered dc to operate, it needs a capacitor. It could be a smaller one, but that probably won't really achieve the result you're looking for.

BTW, you're the first, most people buy the module specifically because they want to eliminate the flicker! That's also why I originally designed it for my use!

For subways only I want flicker. For my other passenger trains they will get this regulator as intended. Yes, I'm one of the odd ones. Anyway, here's what I need to do, get the leds connected to the metal strip.

Attachments

Think I figured it out. I cut the metal strip down. I should be able to solder to it now

Attachments

Success! After some more cutting of the metal I was able to solder the strip in. Ugh. Only 4 more to do on this car and 5 other cars to do. I'll be on this for awhile.