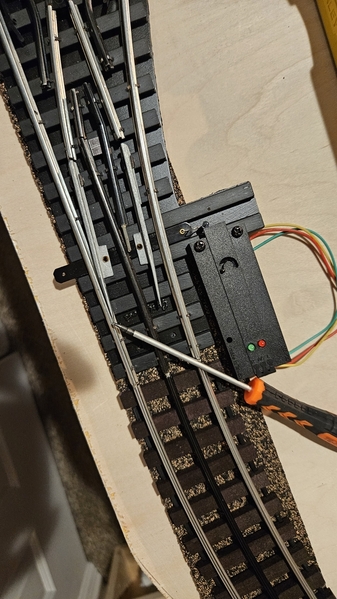

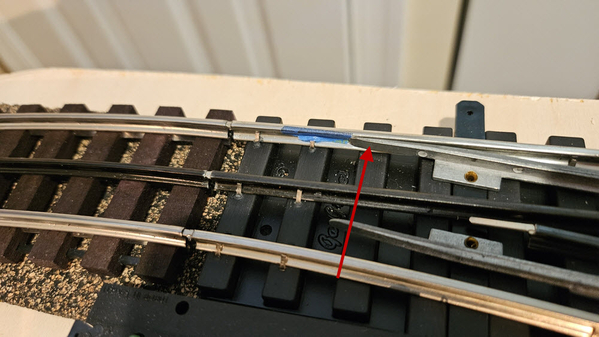

I have recently installed O54 Gargraves on my layout with a Gargraves switch and I'm having an issue with my Legacy Steam locomotives. What they are doing is as they move through the switch they "pick" the switch rails off the outside rails and try to go straight, which then derails the locomotive. See the photos attached, I have the switch set to turnout right which will be the main flow of traffic, with an eventual route that will go straight (not built yet). I have tried to hold the switch tight against the rails manually but the locomotives still pick the rail and climb over the track in the wrong direction.

I don't seem to have this issue with my Lionmaster Big Boy, my diesels, MPC Blue Comet or Post War F3s.

Is there a fix for this or should I contact Gargraves about it?