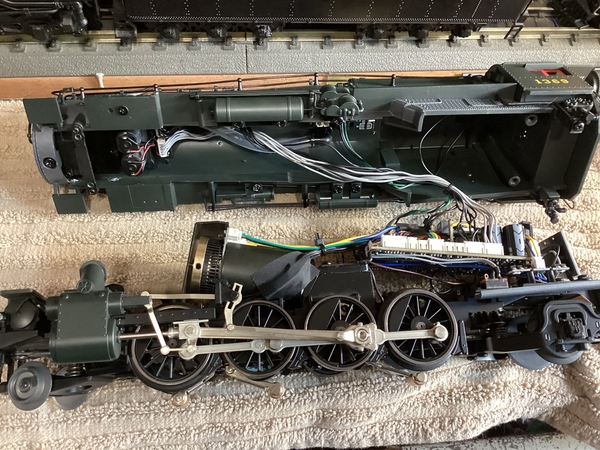

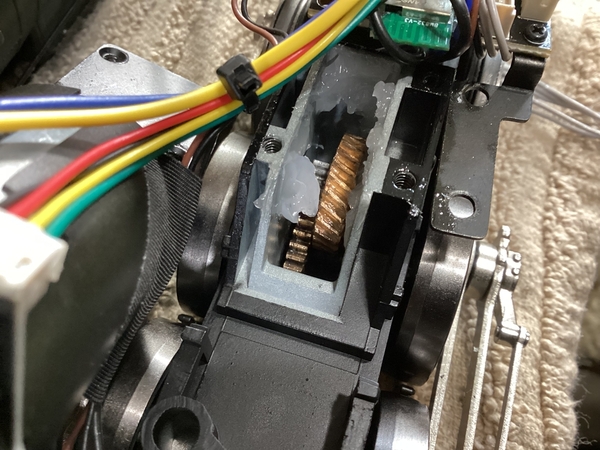

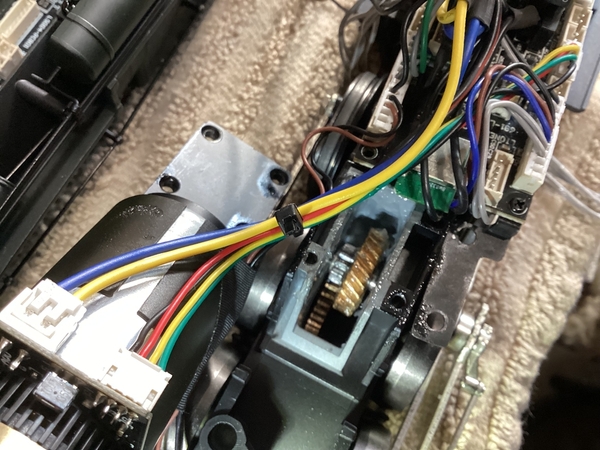

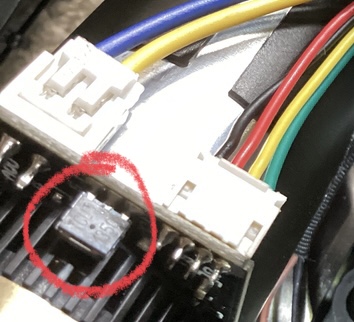

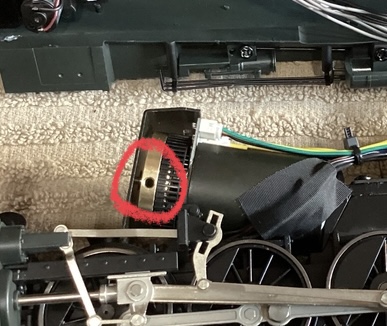

As promised, I’ll start a new thread where we can discuss this newest Lionel Legacy L1 Mikado, …..Dave’s brand new, still sealed locomotive arrived on the doorstep just about an hour ago, ……although ill leave the reviews for the review folks, I will say it is a sharp looking locomotive, I ran Dave’s engine right out of the box, with my normal customary quick lube servicing, and put her through the paces to make sure all features are working as advertised. All works as it should, ….sounds are great, ( as to be expected ) lights all work, and I briefly tested the smoke with just a few drops to verify operation……all that works well,….So after the sound checks, etc, I turned the sounds off and ran the engine,…..Sadly, I must report there’s a lot of noise coming from the gear box area of Dave’s new engine….for this test, I ditched half the cars I normally test with, and used 12 cars, ….it’s a smaller locomotive, so I wanted to give it a fair chance, …..in reverse, pushing the train, it did lock up one time, in an O81 curve, ,and the cab light blinked signaling a motor driver stall. I reset it, gave it a nudge forward, and it ran fine …..for the record, I could not duplicate that scenario…..Those are my observations right out the box, ….I have Dave’s permission to open her up, and we’ll have a look around,…..I’ll observe things as we move along, I’ll note any loose hardware ( if any ) that I encounter,…..then we’ll look at the gearbox….I did video Dave’s L1 running with the sounds off, to verify the noise,….I certainly wouldn’t be happy with that much noise…..I’ll upload the video, after this, and we’ll have a look around throughout the evening……allow me to add, ….I do these kinds of jobs to keep y’all’s equipment on the rails, making you folks smile, …so let’s keep the thread on that target!!…..please don’t bash!!….please don’t condemn, ….start a new thread for condemnation, …..feel free to add suggestions, or ask questions, but let’s keep it civil, solve the problem, and just enjoy it,…..

Pat