More work today, made some nice progress.

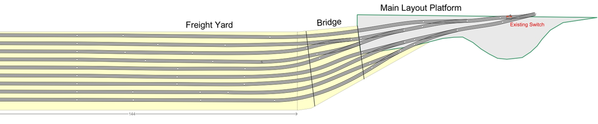

Dropped the wood on and this is the process for creating the curved edges.

After the tracing, fire up the jigsaw and cut to our edge design.

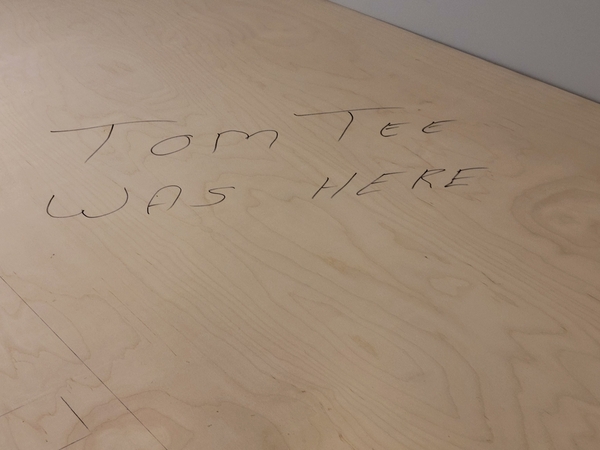

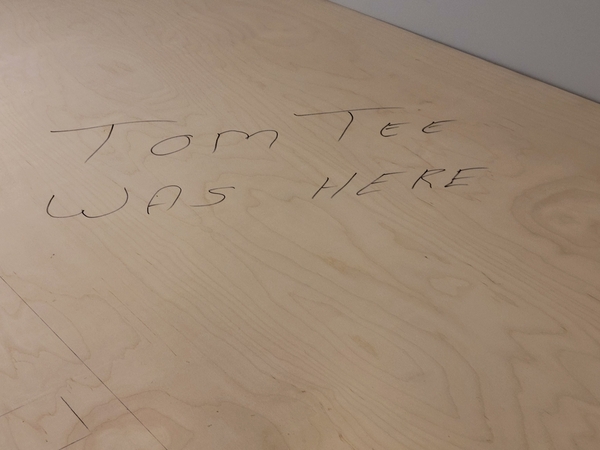

This is a very valuable piece of real estate, a signed Tom Tee layout!

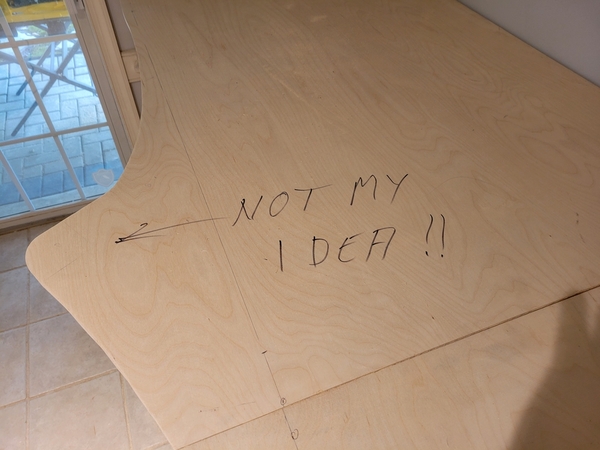

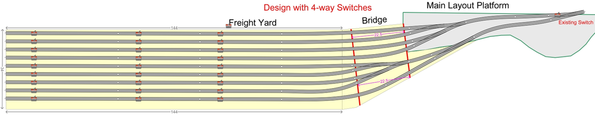

Tom insisted that we add a little bump-out "just in case" I decide to stick an O72 curve to yet more benchwork and who knows what!

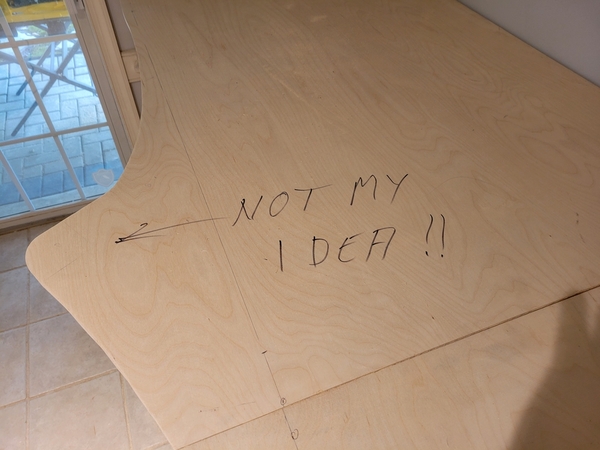

I figured I'd better disown the idea, my better half might not be amused.

We trace all the cross-members from below, then turn over the sheets and drill small holes. This allows us to map out on the top where the beams are to nail down the top.

Next step is to route the Homasote edge after applying it, getting ready for the support blocks and fascia to be added.

All cleaned up, I have to add a couple hundred screws and then apply the filler to create a smooth surface.

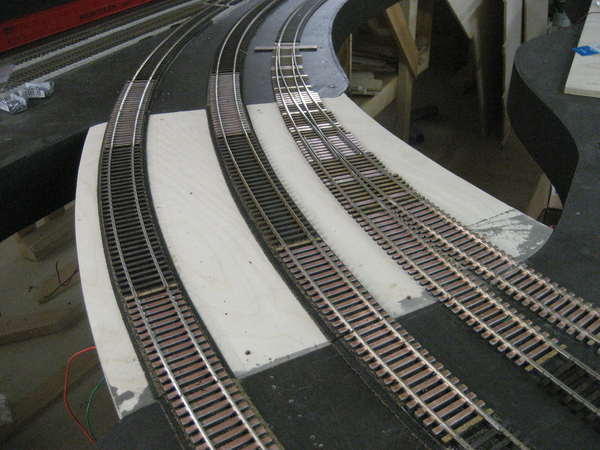

This is the lip that the removable bridge will rest on, before fitting the bridge, we'll add the J-channel to protect the edge of the Homasote so it won't get dog eared.

<<<< Great company to work with.

<<<< Great company to work with.

Amazon,

Amazon,