Looks good John. By the way, whoever built your house did a great job on that wall. Looks extremely straight.

John, Just tell the CinC she will have so much more to see if you add additional trackage and destinations.

@romiller49 posted:Looks good John. By the way, whoever built your house did a great job on that wall. Looks extremely straight.

It doesn't look nearly as straight when you're here. ![]() There's quite a bit of wave to it.

There's quite a bit of wave to it.

@Ron_S posted:John, Just tell the CinC she will have so much more to see if you add additional trackage and destinations.

It's all in good fun, actually she has no issues with my hobby, so I really have no complaints! ![]()

Hi John - how messy was it when you routed the edge of the Homasote. What bit did u use on the router?

Bob, it's not as messy as you think, holding the vacuum right below it sucks up a majority of the dust. It still requires cleanup, but then all the stuff you do building a layout requires cleanup. ![]()

The bit is a straight Formica bit with the bearing on the bottom. The bearing rolls on the plywood and it trims the Homasote to the same line.

Looks great John and Tom. I see a curve in your future, bending around in front of the sliding door to the wall on the other side.

Chair rail in the basement? I guess it went well with the dress up columns. ![]() My wife stays busy quilting so she's never quite sure what I'm up to down in the basement.

My wife stays busy quilting so she's never quite sure what I'm up to down in the basement.

I love curved layout perimeters - and you have a master - Tom Tee.

Why use Homasote in a yard area?

And, is the bump-out section where the a turnout will lead to the lift bridge to cross the isle, or what is its function?

@turkey_hollow_rr posted:Looks great John and Tom. I see a curve in your future, bending around in front of the sliding door to the wall on the other side.

Chair rail in the basement? I guess it went well with the dress up columns.

My wife stays busy quilting so she's never quite sure what I'm up to down in the basement.

Yep, you never know what might pop up on the end of that curve. ![]() I think Tom was just trying to let me know what the next project is.

I think Tom was just trying to let me know what the next project is. ![]()

![]()

The chair rail came with the house. I removed it on the opposite wall in that area where I'm putting shelves, but since it wasn't in the way for the main layout or this yard extension, I couldn't see going to the trouble of ripping it off. I kinda' wish I'd ripped it all off when the basement was empty, it's just a dust catcher, nothing more.

@Paul Kallus posted:I love curved layout perimeters - and you have a master - Tom Tee.

Why use Homasote in a yard area?

And, is the bump-out section where the a turnout will lead to the lift bridge to cross the isle, or what is its function?

It's great that the yard will match the main layout area with the fascia, etc. The Homasote helped level things, and I had it left over anyway. The bump-out will lead to a ??? It's really there in case I change my mind about yet more expansion. Tom had a great idea, we put a turnout there and suspend a broken locomotive in pieces from wire down to a bucket on the floor. ![]()

Yes, I saw your earlier post about the previous owners. I guess they had a vision. ![]() I know what you mean about dust collectors, I just painted the wainscoat molding in our foyer. Took some doing to get the top of the molding clean.

I know what you mean about dust collectors, I just painted the wainscoat molding in our foyer. Took some doing to get the top of the molding clean.

Homosote does make for a flat, consistent surface and it's easy to attach things to it. You guys are going to have to fill in ???, I have a bruise on my hip just looking at it.

Well, I don't walk back there too much, but I am contemplating adding the switch to nowhere just for fun to it. I think I'd pin the switch so it couldn't be thrown into the "out" position by mistake. I can just see it now, backing a string of my Vision Line Tank Cars onto that siding and having them cascade to the ceramic floor! ![]()

Some of the bit styles I used on john's Layout.

Router bit with bottom tracing bearing.

Router bits with top and bottom bearing.

When working with decorative hard woods or finished material like laminates I use a square bearing so it will not spin against the material.

You can add square bearings to your existing bits.

Attachments

Attachments

@Tom Tee posted:When working with decorative hard woods or finished material like laminates I use a square bearing so it will not spin against the material.

You can add square bearings to your existing bits.

Love the square bearings, never saw those before. Many years ago I did some Formica tops when Formica was all the rage, and I still have the bits I used for that work, but no square bearings. ![]()

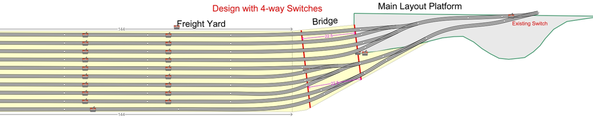

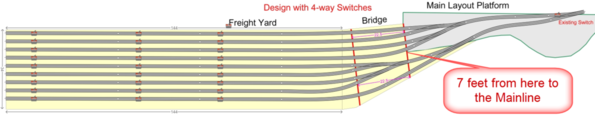

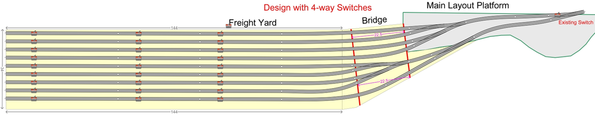

Changed up the freight yard switch matrix. Now that I have a wider bridge, it was practical to use the 4-way switches that I already have, so I just need to pick up one #6 RH switch and I'm all set.

Attachments

Where did you get the homesote John?

@Tom Tee posted:

I've done a lot of woodworking, but had never seen that design - thanks. The shearing action probably leaves a smooth cut.

Where do you source them?

Also, how long do they last? (Looks like they aren't easily resharpened.)

Duck, They are Infinity Mega Flush brand, available at better wood shops and Amazon. They provide a nice clean edge. Great for hardwood and expensive projects. Not really needed for bench work. They cost more than normal and last more than normal. I do not resharpen bits, Just move them to the back of the drawer.

It's a down shear trim bit. Tom's are top of the line Whiteside but I'm not sure if those specific bits are still available. Their ultimate trim bits are around $160 each, but compared to a Woodworker II saw blade they are still reasonable for the results. For my bench work a $35 Freud works ok. ![]()

My bad, I'm not familiar with that brand.

Homasote availability can be discovered by calling the Homasote mfg in NJ. They will let you know who the distributor is in your neck of the woods. Then call that distributor and ask them which retailer handles Homasote in your market.

Check with a better real lumber yard. HD and Lowe's can be variable in which store carries which product.

Even if you find warped Homasote, negotiate a better price and store it flat. It will assume the surface on which it is laying within two weeks.

@gunrunnerjohn posted:

A few comments on the yard John. Not sure how you plan to use it but....

1- I don't see a run around for backing out an engine that pulls into the yard. I know you can run in both directions on the layout so adding a couple of switches between tracks 4 & 5 (from the top), might be beneficial.

2- Do you have enough lead track so that you don't foul the main when working the yard?

Bob

@Tranquil Hollow RR posted:Where did you get the homesote John?

I got it at HD several years ago. However, when I was in HD a couple days ago, there was a stack of it in the lumber section.

@RSJB18 posted:A few comments on the yard John. Not sure how you plan to use it but....

1- I don't see a run around for backing out an engine that pulls into the yard. I know you can run in both directions on the layout so adding a couple of switches between tracks 4 & 5 (from the top), might be beneficial.

2- Do you have enough lead track so that you don't foul the main when working the yard?

Bob

1: Tom and I were discussing "escape switches" between some of the yard tracks, that would be easy to add.

2: I have all the lead that I have room for, so I don't have much of an option to add more. ![]()

I figured you have thought this through John. Just armchair modeling here ![]()

Everything looks great !

Given the space available for the yard, I tried to use all I could. Whatever happens here has to happen in this space. ![]()

Attachments

John,

Like in the real world, you make do with what you got.

I like the yard extension, I'm keeping all my wyes left from my layout just for a bigger yard in the future at whatever location we wind up at.

Gunrunner John, the new yard is Fantastic, and very creative, you are blessed to have a great carpenter friend for help and ideas. Good tools to work with are a gift, one never has enough tools. Coupled with your electronic capabilities, this will be a fun to run model railroad and thank you for the updates. Happy Railroading Everyone

Thanks guys. ![]() I'm looking forward to having more room to play. In checking track spacing, etc. it appears I "may" be able to squeeze in ten tracks on my yard!

I'm looking forward to having more room to play. In checking track spacing, etc. it appears I "may" be able to squeeze in ten tracks on my yard! ![]() Why not, never have enough yard space!

Why not, never have enough yard space! ![]()

Attachments

With a little help from the peanut gallery maybe, just maybe, we can encourage John to swing the 180 bridge now for increased yard space and additional engine facilities. ![]()

Go for it, John!! The peanuts have spoken. 😉

@Tom Tee posted:With a little help from the peanut gallery maybe, just maybe, we can encourage John to swing the 180 bridge now for increased yard space and additional engine facilities.

Let's leave the peanut gallery out of this! ![]()

![]() I want to get this part finished before I start adding more benchwork!

I want to get this part finished before I start adding more benchwork! ![]()

@Bob posted:John, for what it's worth to you, I was able to fit 7 tracks on a 24" wide shelf using 3 3/8" center to center track spacing.

I mapped it out, and it looks like 10 tracks fit just right. Shaving 1/8" doesn't allow for an 11th, so I'll stick with the 3 1/2" spacing. ![]()

@Bob posted:Mine is double-deck, too.

I don't have enough space to get down to a second level, that would be about a 10" drop from the surface. I suppose that bump-out could lead to an O72 circle of track to get me down to the lower level, that would be interesting. ![]()

Gunrunner John, I do not know if you’ve ever been to Bobs home (shown above) to see his really cool layout, however if I remember, a train can actually go in a tunnel and. have 6 or so curved siding tracks that will hold entire trains, one storage yard above the other, and one way in, and one way out, therefore allowing Point to Point realistic operation. One of his main features is Horseshoe Curve, a fantastic scenic site. Your layout is coming right along. Happy Railroading Everyone.

While I'm aiming for "nice", I have no illusions of matching some of the amazing layouts I see here and elsewhere, I have to temper my expectations. My space for the yard simply did not allow for entry/exit on both ends, so that ain't happening.

Moving along, got all the blocks for the base layer of fascia cut, getting out the clamps, PL3 adhesive, and nail gun for the next step, mounting them under the table.

Attachments

Looks like you have room for a helix. Could go up or down or both.

Charlie

I think a helix permanently in front of the door would be a major problem! ![]()

![]()

RATS, ran out of clamps, more gluing tomorrow!

Attachments

Hi John ,

some nice work you guys are doing , I’m glad to see you are enjoying your layout.

Alex

Thanks Alex, I an eager to get my yard functional so I can break out some of the freight cars and have them available. ![]()

@gunrunnerjohn posted:While I'm aiming for "nice", I have no illusions of matching some of the amazing layouts I see here and elsewhere, I have to temper my expectations. My space for the yard simply did not allow for entry/exit on both ends, so that ain't happening.

Moving along, got all the blocks for the base layer of fascia cut, getting out the clamps, PL3 adhesive, and nail gun for the next step, mounting them under the table.

Ah John, nice is in the eye of the beholder. So what you have no entry/exit on both ends. Just get a great switcher in there to move stuff about. Whenever I get to building mine, I just have spurs on my design. No space for anything at all, but that'll do. Just needs some kind of functionality to provide something than a loop or loops. I remember someone saying(or most people), to have at least two main lines or separate running tracks so there is something other than watching one engine doing all the work. I just have to get things moving along. Guess I need a switcher for that, lol.

You can never have too many clamps, John! ![]()

"To Infinity! and beyond!" ![]()

George

@Dave NYC Hudson PRR K4 posted:Ah John, nice is in the eye of the beholder. So what you have no entry/exit on both ends. Just get a great switcher in there to move stuff about. Whenever I get to building mine, I just have spurs on my design. No space for anything at all, but that'll do. Just needs some kind of functionality to provide something than a loop or loops. I remember someone saying(or most people), to have at least two main lines or separate running tracks so there is something other than watching one engine doing all the work. I just have to get things moving along. Guess I need a switcher for that, lol.

I have a bunch of switchers, both diesel and steam, so I'm set there. I'm contemplating some escape switches on several of the yard tracks so I can drive stuff in and then move the locomotive out from the end of the yard track. I think I can cut down the Ross Regular 100/101 switches so they'll work with 3.5" between centers, at least it looks like it'll work in my layout program.

<<<< Great company to work with.

<<<< Great company to work with.

Amazon,

Amazon,