This is what I love about discussions on this board that come up, brings up different viewpoints and allows me to think about what is good for me. I agree that given the run length on your layout, Arnold, that 14gauge is the way to go. In terms of feeders, unless you are running them a long distance (which kind of negates the bus concept), 16 is plenty big, lot of people use 18 gauge for the relatively short runs that feeders represent, might be easier to work with 18 gauge whether lockon or soldering to the track.

Couple of things I have promised myself with the wiring:

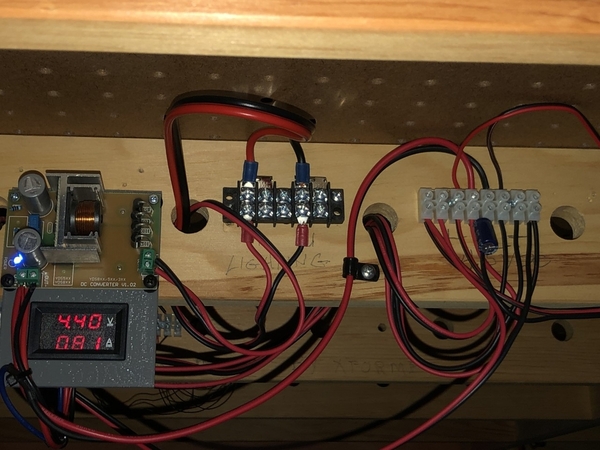

1)Use distribution block to feed the wiring for the blocks out to the track (I am wiring conventional block to start). In the past did some crazy kinds of many to one wiring, wasn't great.

2)As much as possible, use color coding with the wiring. If I can't get colored wire, then I will use colored labels or colored tape to show what it is (for example, my current wiring plan calls for purple wire for the DCS feed to the track). With color coding, it is possible to create a wiring diagram using the same color coding. Having traced wiring in cars, the color scheme they use in the harness makes life at least a little bit better when debugging. I also think labels indicating where the wire is going is not a bad idea, for example, in my block 1, having a label "P1" (power 1) would be valuable. I am going to use a common buss that will be available easily in any part of the layout. If I use 2 transformers, I will use a common ground (and phase them), to not have 2 common busses out there.

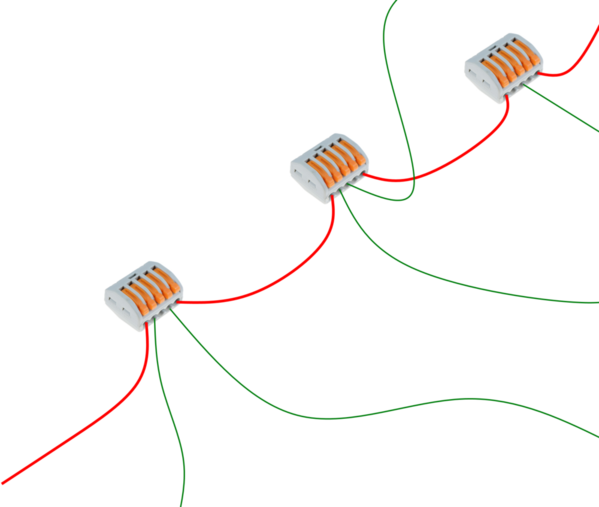

3)Use suitcase or wago connectors where possible, and use spade lug and crimp connectors to keep connections neat and minimize soldering.

4)Under the layout, I am going to use something like plastic cable clamps to run the wire through, rather than stapling wires to the underneath or running through drilled out holes in the frame. With these, you can open it up is you need to get access to a wire when tracing or doing something else.

5)Going to try not to overbuild. In my case, given how relatively small my layout is, not overdoing it. In the past I had feeders every couple of feet, which was overkill, given the length of my blocks prob having 2 feeders will do it per block.

Wish you luck, taming the flying bowl of spaghetti is kind of like weeds in a garden, you have to actively seek them out and eradicate them .

.