REVISED!

Before I get into the nitty gritty details, I need to give "Special Thanks" to 3 people for going above and beyond with this project:

1)Harry Henning and his folks are great to deal with and are so honest, it is refreshing. No wonder why his store has been around so long.

2)David Johnston must have worked in a prior life at the Lionel factory assembling prewar steam switchers. How he knows what he knows is beyond me. I could not thank him enough for his support.

3)My friend Bill who has the unenviable job of helping me out when things go wrong with my switchers.

(honorable mention to Myron Biggar for the set of screwdrivers he gave me at a Greenburg train show at Yonkers Raceway, back in the 1990's)

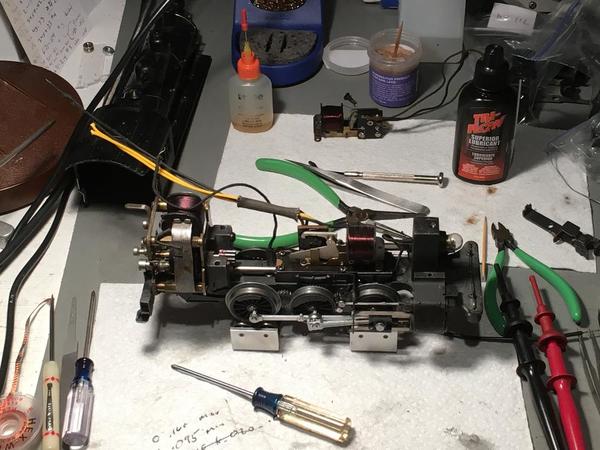

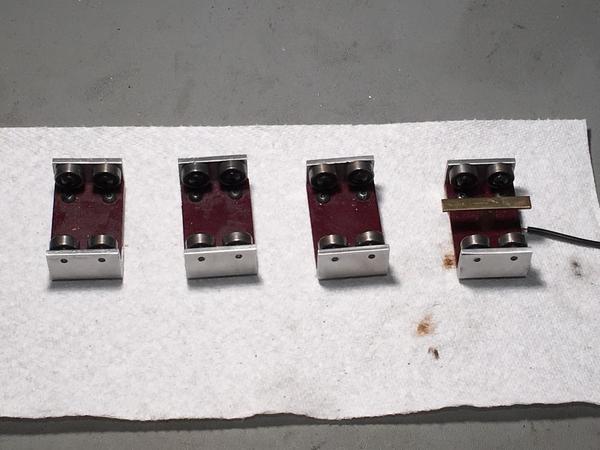

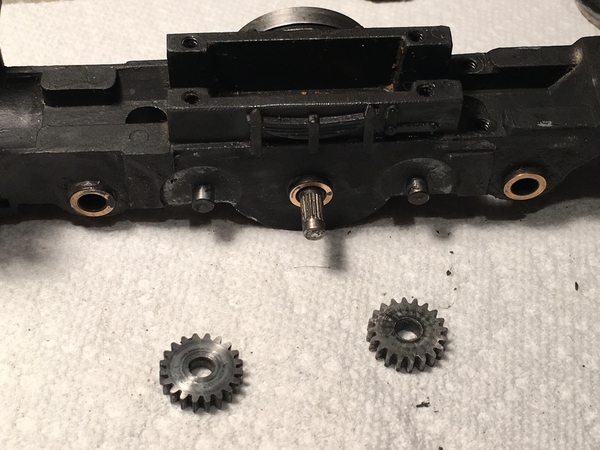

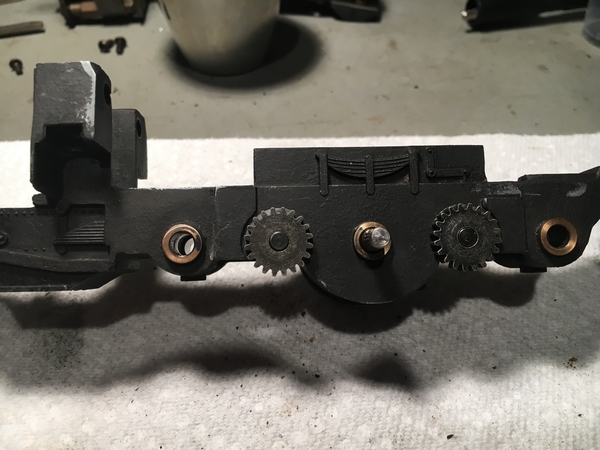

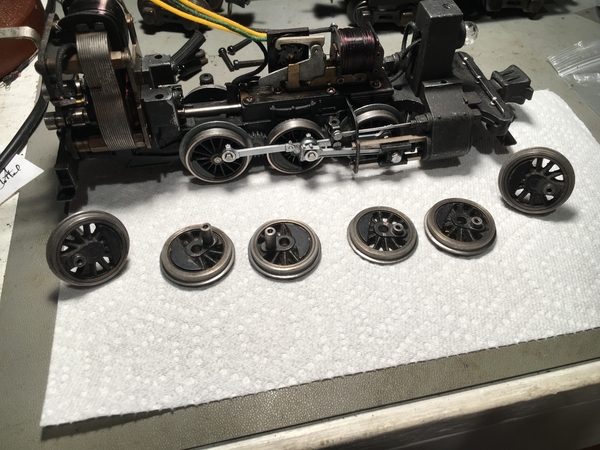

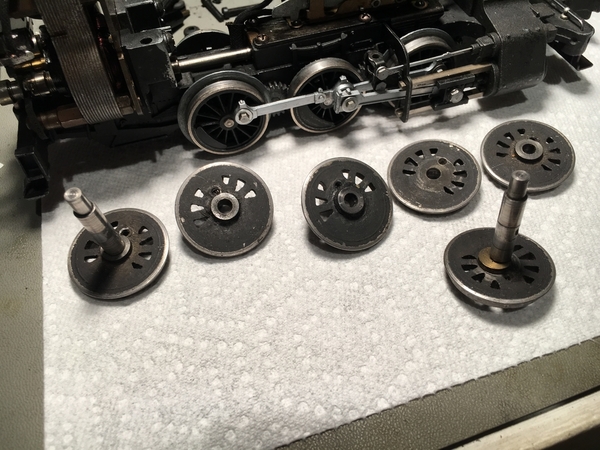

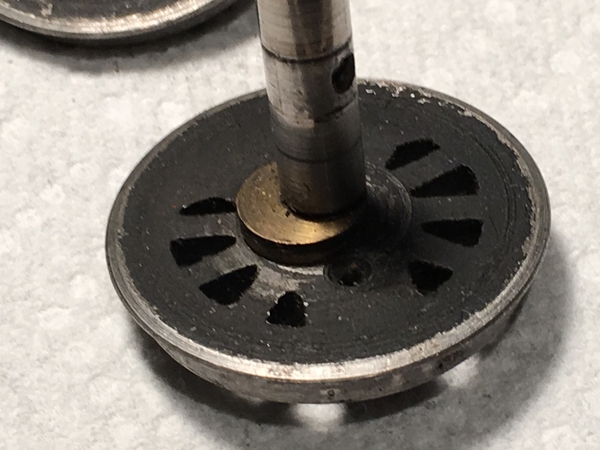

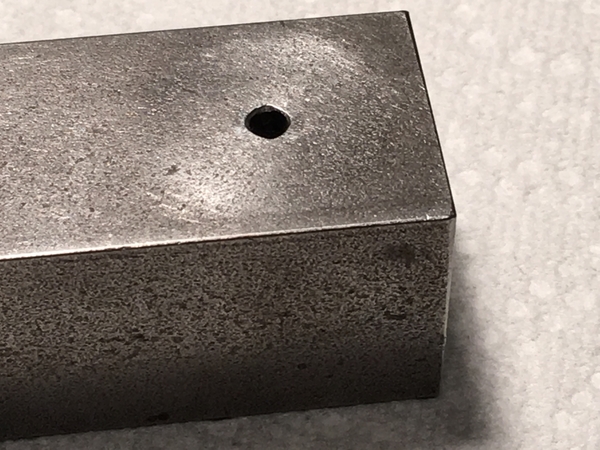

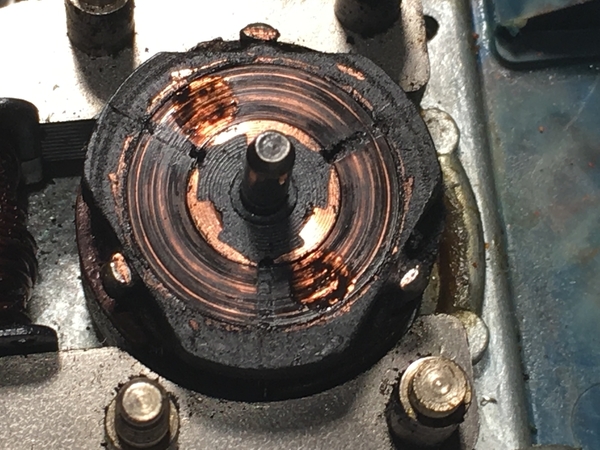

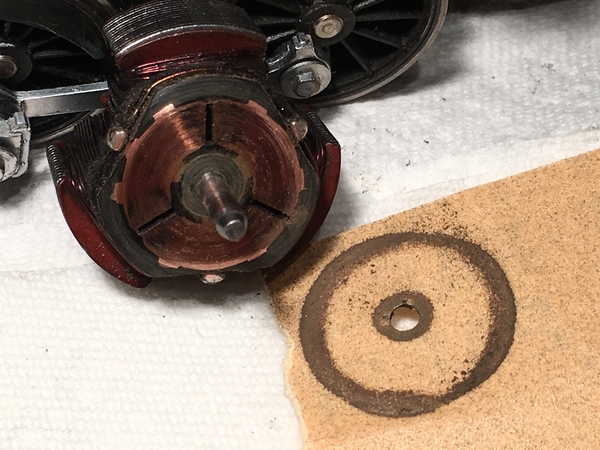

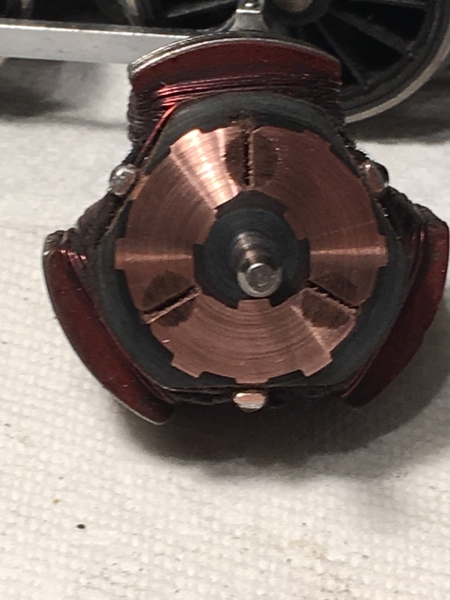

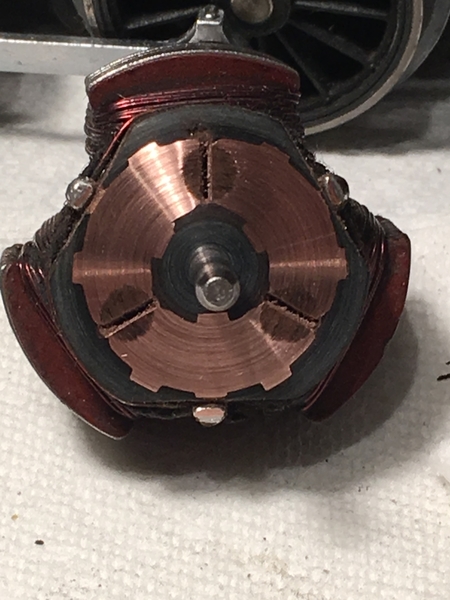

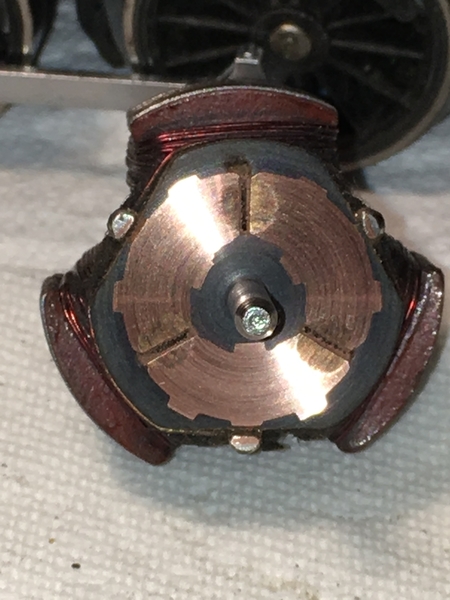

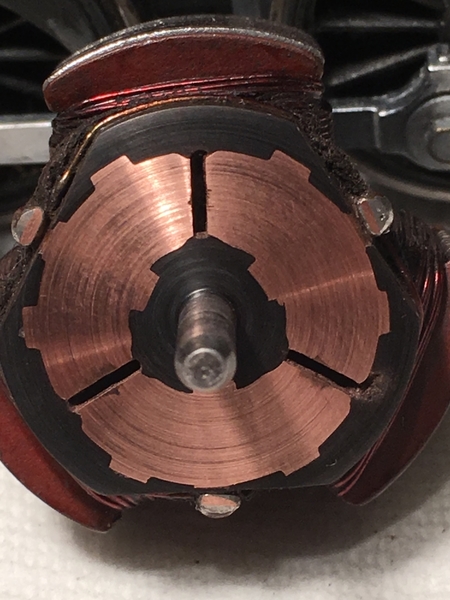

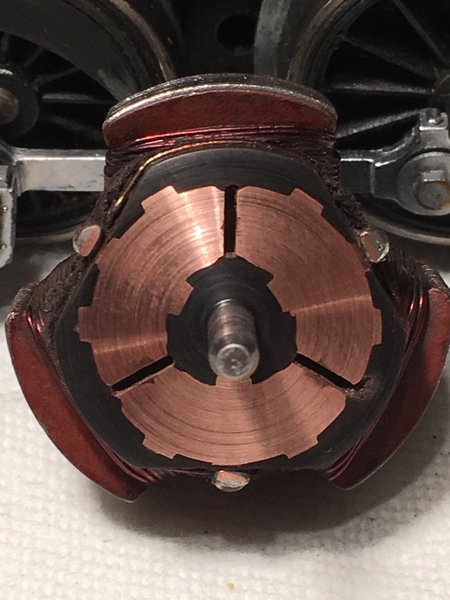

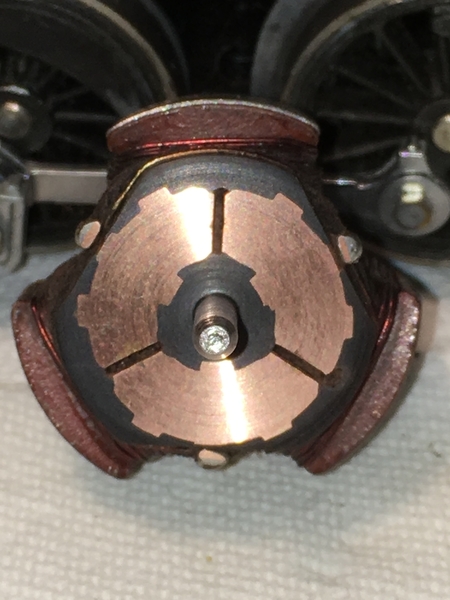

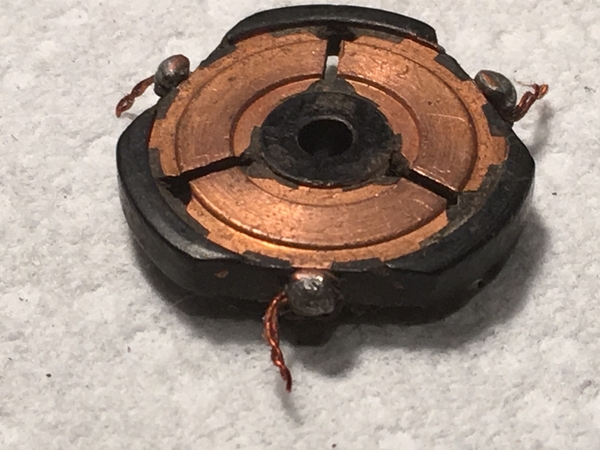

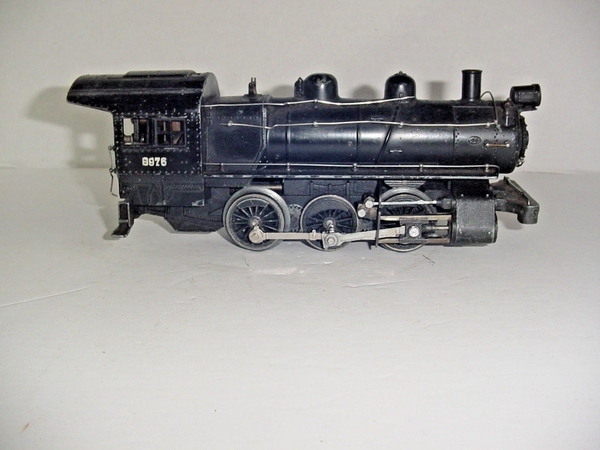

I recently got back my "basket case" of a locomotive from Harry Henning. Harry had the lower half of the locomotive assembly. Now keep in mind that this locomotive was severely abused by a prior owner and it needed lots of work. Some of what was needed included: rewinding the coil for the e-unit, I believe all of the wiring was replaced, the drivers were dinged and dented needing replacement, the idler gears were shot and needed replacement...and that may just be a fraction of what Harry and his folks worked on. Luckily, I had a donor locomotive that I bought years ago if ever needed for such a project. The donor steam switcher donated drivers and idler gears.

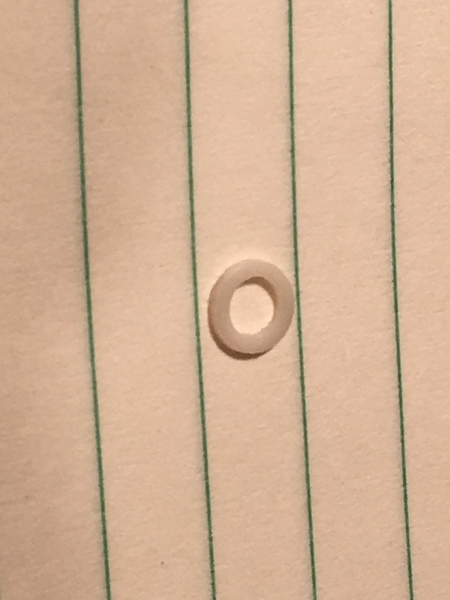

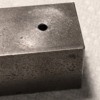

While that was happening, my friend Bill, who helps me with the less severe types of repairs did some great work on the cab roof. The cab roof was no longer "round" most like from a drop or several. It also had a rip/tear on one edge. Bill hammered out the rip and then we figured that we should try to reinforce the roof. Looking around his basement, I noticed a familiar shape and asked, how about this tuna can? So, Bill used tin snips to cut a small section out of the can and then we epoxied it to the underside of the cab roof. I wonder if the cats in my house will have an unnatural attraction to this particular locomotive now!

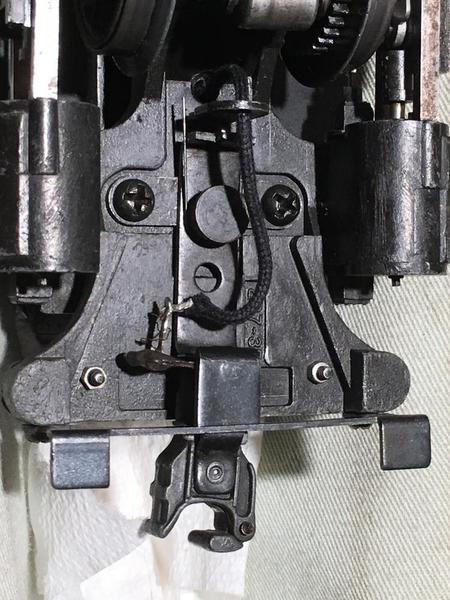

Tonight...Upon receiving the lower assembly back from Harry Henning, I still needed to do some minor work. Tonight was a pretty big step forward. I had to flip a plate under the e-unit, I wired the headlight to the new wire Harry left for me, I drilled out the repro 653 number plate for the new smokebox assembly and replaced the 653 number plate with a new old stock #227 number plate which is more representative of the vintage nature of this locomotive.

So, how does it run? I had emailed David Johnston earlier today and he gave me some more advice. The last sentence summed it all up. He said:

Should run like a Swiss watch.

By the way, she does! I could not have been happier.

More to come in the next few weeks:

- Putting all the rods back on

- Putting the front smokebox assembly on

- Putting the boiler shell on

- Putting on the front pilot/steps

- Running it with the #2232B tender purchased to be its mate

- Replacing the missing marker lights on the boiler

So, summing up... here we have a locomotive that is in its mid to late 70's as far as age, made in the USA when this type of craftsmanship was indeed like a Swiss watch and it now ready to start another 70 years of operating.

Thanks again for everyone's interest and support.

Tom

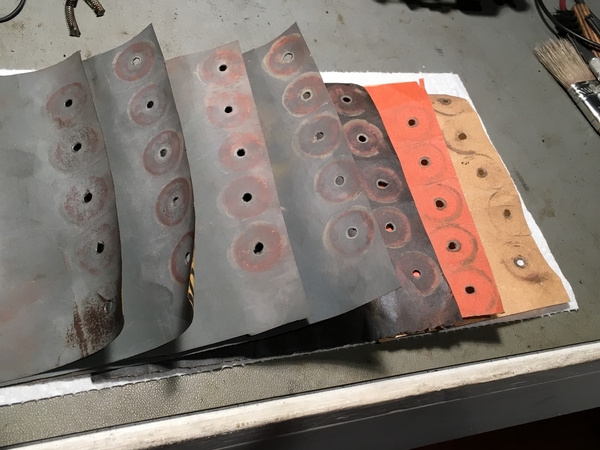

Edit from Spring 2024- It was around this post that we used a Krylon can of black (flat) if I remember correctly...taping off all but the cab roof. So, the top of the cab roof got a coating to cover the repair we made. In one of the photos below (2 down from here), you can see the lines of the tuna can we epoxied on the underside of the cab roof. Also, if it gets confusing to follow, I changed by OGR handle from "MNCW" to "PRR8976."