Hello fellow forum members. I finally started building my layout last year. My layout is 10x14. When I started, I went with Fastrack since I already had some from my carpet central. However, I've gravitated to mostly scale-sized or close to scale size locomotives and rolling stock. Most of my current roster is MTH Premier. I want a track system that is more realistic than Fastrack. I've heard lots of good things about Gargraves and Ross switches and I know many of you use them and love them. I'm considering making the switch and welcome opinions. Because my layout is already wired using the star system (power is the Z4000 and I use DCS), how easy/hard would it be switching the existing lock-ons to Gargraves track? How is Gargraves flexible track? I also noticed they make tinplate and stainless steel rails. Please advice! Thanks so much!

Replies sorted oldest to newest

We used Gargraves and Ross switches, tinplate... didn't have the need for extra expense with stainless. Not sure about the lock-ons because we soldered directly to the bottom of the rail, out of sight. We used 18ga brads to fasten the track down instead of screws. Painted the rails, added ballast, and it was a lot cheaper than Atlas, more variety than MTH Scale Trax.

It's all a matter of opinion here, and you will here it all. I think the most commonly used across all 3 railers is Gargraves and Ross. It's cheaper, readily available, and looks just fine.

The flex track isn't too hard to bend. Various opinions and techniques there too. We used sectional curves, and flex track where we needed a custom curve... all wood ties.

Attachments

Attachments

Gargraves has track pins with the feeder wires already soldered on. Just line up your track joints with the location of your existing feeders. The flex track is super easy to use. Just put a couple of screws at on end and then just work it where you want to go. Depending upon how tight the bend is, you'll probably want to cut the ends square after bending. As for SS vs tinplate, I love the SS stuff. For whatever reason, it just stays cleaner than any track I've ever used.

Gilly

I use/used the stainless just because. I like Ross Switches and Gargraves track. Great people who will help you with a problem...

Thanks guys. This really helps. How difficult is the wiring for the Ross switches? It sounds like this would be a fairly easy switch to make.

I used GG tinplate Phantom Flex on my last layout and it was very easy to bend and solder--the Phantom rail is easier to solder if some of the black plating is removed to expose the tinplate. And all Ross switches. Track was painted using Floquil rust brown, and ballasted with Woodland Scenic products.

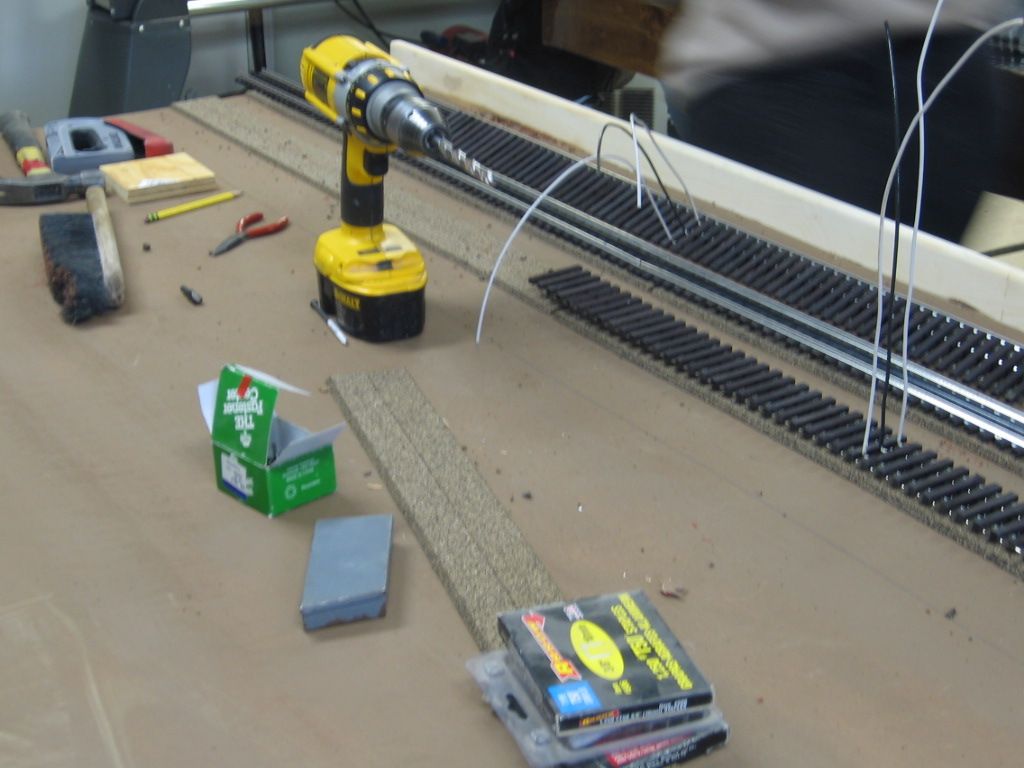

As for attaching the track, I used two hand drills. One had a countersink attachment for #4 black screws, and the other a #1 Phillips head bit--went very quickly; all screw heads were even with or below the height of the ties.

There was a photograph in the "Rail Bender" thread that was up for the past several days showing the jigs cut to various radii for use in bending GG flex track.

GG sectional curves were used on my 'round the tree loops this year. It is very fast to assemble compared to GG flex track. If you use sectional track, try using one or two size larger radius pieces at the beginning and ends of curves to simulate prototype easements--it flattens out the sharp curves most of us deal with due to limited space.

There are tons of threads on bending, painting, soldering, and ballasting GG track--you won't lack for reading material and photos.

For whatever reason, it just stays cleaner than any track I've ever used.

Gilly

The tinplate track DOES get dirty real fast. That's about the only draw back I can think of. If you have older Post War stuff, the magnatraction don't work on stainless rails.

Thanks for all the suggestions. Pingman- thank you for the suggestion of using the sectional curves at the beginning and end of curved areas. My current layout is 0-72 on the outer mainline and 0-60 on the inner. There is someone selling a case of new, tinplate phantom flex track, 51 pieces, for around $370 on EBay. Is that a pretty decent price?

I use/used the stainless just because. I like Ross Switches and Gargraves track. Great people who will help you with a problem...

My layout uses Gargraves track and a combination of Ross and Gargraves switches. While both are fine products I would have to give the edge to Ross, especially on switches as the trains run so much more smoother over them. Gargraves track is very good but the individual staked rail of the Ross tracks look a bit better to me. If I had to do it all over again, I would use Ross switches 100% and more Ross track.

One more happy Ross/Gargraves user. Over 8 years and ALL the switches still work perfect. Minor effort for track cleaning. I too solder connections to the bottom of the rails. On the switches give serious consideration to the Ross 11 degree switches. They are ideal for a cross over, you can achieve very close track spacing as compared to the 42 or other curved switches. Have fun!

Thanks for all the suggestions. Pingman- thank you for the suggestion of using the sectional curves at the beginning and end of curved areas. My current layout is 0-72 on the outer mainline and 0-60 on the inner. There is someone selling a case of new, tinplate phantom flex track, 51 pieces, for around $370 on EBay. Is that a pretty decent price?

Check Trainworld, a forum sponsor.

Interesting, Ro is $40. more per case. That's a lot of shipping!

It's $329.95 for a box of 50 plus $9.95 S/H at RO ... phantom flex tinplate

TW is $379 per case and they charge more for S/H

Yep, sorry, your correct. Silly me, I was looking at stainless. And that is the best price I've seen.

Actually, I just bought a(nother) case from Train World the other day. $316.94 shipped. You have to really look carefully at the different items, but it's there.

Thanks so much everyone. I've purchased from Train World and Ro before so I will check them both out.

On both my home layout and the TMB Club Layout Gargraves track and Ross switches were used.

On the club layout which was rebuilt due to a location change we used approx 400 sections of GG track we were salvaged from pour old layout as well as 12 cases of new GG.

Just make sure you are skilled with a Dremel and get the bigger cutting blades and mandrils which make better cuts!

Steve

Gargraves track and Ross Switches. Gargraves may be the least expensive track available, IMO. Ross Switches may be the most reliable, IMO. Both match and can be ballasted to look well. Fort Pitt High-Railer layout.

Ballast is from Brummy's Landscape Express. A colored, rubber crumb, ballast.

Midwest cork road bed is used under the track.

ModelMaster Railroad tie brown has been air brushed on the sides of the Rail.

The Three way switch pictured, is a Ross 204 switch with two DZ 1000 switch motors.

Click on the underlined phrase to link.

![]() Mike CT

Mike CT ![]()

I appreciate all the input. Does anyone use Gargraves switches at all? What is the quality? I noticed they are a little cheaper than Ross. Just doing my due diligence. Thanks!

Ross makes the best switches; it's not even close. I purchased one Gargraves switch going in to my coal mine on the layout--that was a mistake.

Scott Smith

Ross makes the best switches; it's not even close. I purchased one Gargraves switch going in to my coal mine on the layout--that was a mistake.

Scott Smith

Ditto, gave up on there switches long ago. Don't expect their curved sectional track to be the advertised radius either. Their flex track is just fine.

I also use Gargraves and Ross track and Ross switches.

Gargraves track is embedded into each tie whereas Ross track is held in place with spikes, at least every piece I have has been that way. They mate up fine. I think Gargraves 072 sections are shorter than Ross (i.e. takes more pieces to make a circle) but other than that they can be used together.

IMO Atlas solid rail track LOOKS the best, but man-o-man is it expensive.

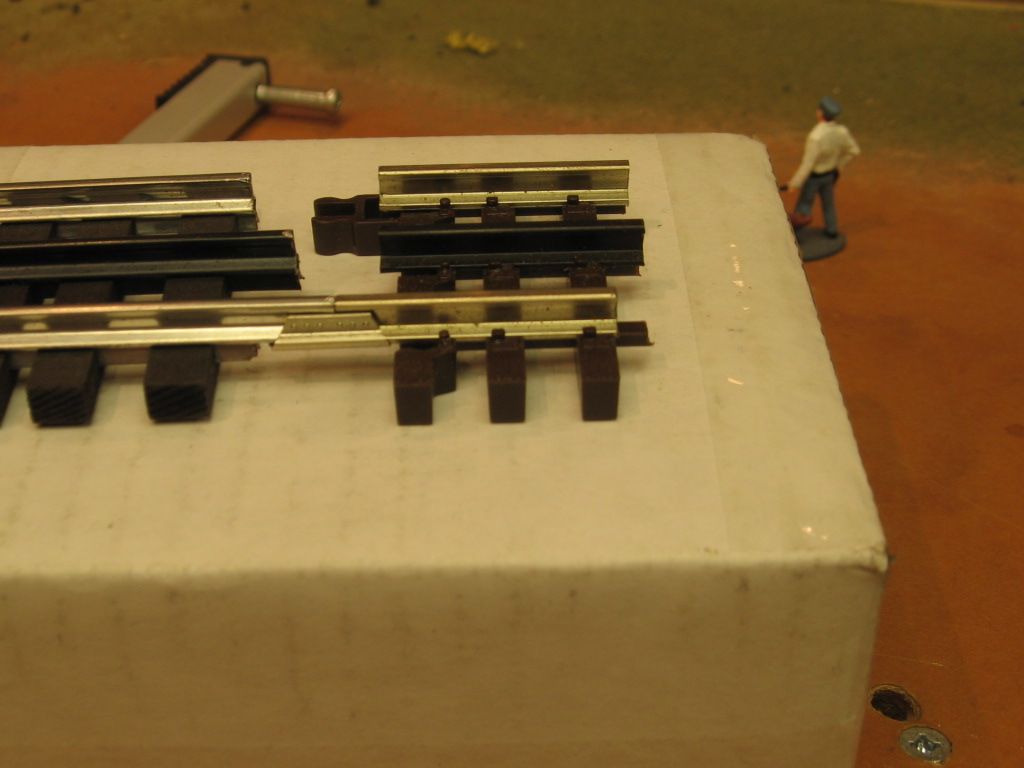

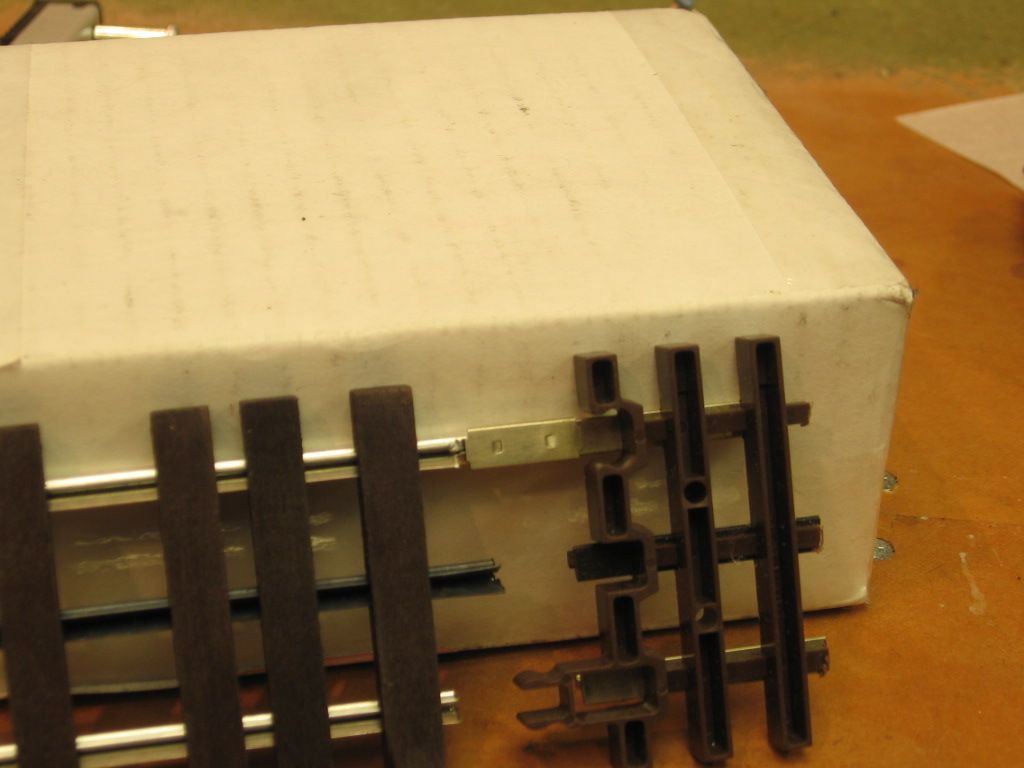

The Gargraves profile is different. Picture of Gargraves connected to Atlas track using an Atlas track joiner. Gargraves (left), Atlas (right). Note that the bottom of the track profile, that is embedded in the cross tie, has to be removed, with a Dremel, to do this connection. Gargraves, like Ross, uses track pin connections. Some would complain about the oversized tie. They work well for installation and attachment. With Flex track, the ties can be moved on the rail. You can note spacing difference in the picture.

14 gauge solid wire soldered to the bottom of Gargraves Track. Black material has to be removed, usually with a dremel tool.

A frustrated layout planner here who is dissatisfied with ALL of the 3 rail track systems.

Mike's photo above shows very well the outsized ties and rails of Gargraves and Ross compared to Atlas. Regretfully, even the Atlas rails are too tall and too big overall and appear crowded in the 3 rail configuration. Yes, Ross and Gargraves are good and virtually trouble free but suffer greatly in the appearance department (IMO)

I'm not interested in converting to 2 rail but would love to have a better 3 rail system. Imagine Scaletrax rails with their inverted 'T' for the center sitting on Atlas' excellent tie system. Of course, Ross would have to build the switches from scratch...

I really appreciate all the input and feedback. This has been very helpful. I think I'm going to go ahead and order a case of GarGraves from Trainworld ($299.99 for a case of 50 flex track). Looks like I'm also going to go with Ross switches. Where is the best place to buy them/best price out there? Now I have quite a bit of Fastrack to sell...

Gargraves track is hollow. That means if someone is sloppy and drops things on the track, like hammers and such, the track can get dented. That dent can cause derailments and rough running. Gargraves is fine if everyone around the layout is CAREFUL with heavy objects.

First telephone order yesterday to CT McCormick Hardware(cttrains.com) for Ross switches, pricing seemed good, customer service good, large inventory of Ross switches.

John

Gargraves track is hollow. That means if someone is sloppy and drops things on the track, like hammers and such, the track can get dented. That dent can cause derailments and rough running. Gargraves is fine if everyone around the layout is CAREFUL with heavy objects.

I'd be more alarmed at the damage to the locomotive than the hassle associated with cutting out a section of painted/weathered and ballasted track.

I'm looking at using the GarGraves Flex track on our next display. By the time it's done we'll probably use about three cases. We'll have 14 tunnels, so Gilly's comment about the stainless needing less cleaning is appealing.

Is the Stainless Flex Track harder to work with?

Are there any special tools or hardware exclusive to working with Stainless track?

What is the minimum curve you can bend it to?

Is the Stainless Flex Track harder to work with? Nope

Are there any special tools or hardware exclusive to working with Stainless track? In the style of Austin Powers, I use my belly to bend it.

What is the minimum curve you can bend it to? I keep a piece of 072 sectional track handy. It is used to ensure that my curves are no tighter than 072.

To cut it, I use this saw from Harbor Freight.

We used Gargraves switches on our hi-rail layout in 2000. They were not reliable at all. A few worked but most were problematic and I found myself avoiding switching maneuvers, etc. because of the frequent derailments.

Ross were about twice the price at the time and I should have bitten the bullet and just went with Ross.

The quality might be better now but I know that Ross switches are still bullet proof.

Gargraves sectional and flex track are just fine.

Is the Stainless Flex Track harder to work with? Nope

Are there any special tools or hardware exclusive to working with Stainless track? In the style of Austin Powers, I use my belly to bend it.

What is the minimum curve you can bend it to? I keep a piece of 072 sectional track handy. It is used to ensure that my curves are no tighter than 072.

To cut it, I use this saw from Harbor Freight.

Thanks Gilly, as usual you remain consistent in being a helpful asset to the forum. Amazing considering how much time putting together your own fantastic creations must take up.

Much appreciated.

In one of the recent threads, I compared the cost of several Gargraves suppliers. Broke it down to cost per piece to include shipping.

Ross was the cheapest if memory serves correctly. Do a search and you may find it.

I use Gargraves flex track with many pre 1991 Gargraves switches, a few new style Gargraves switches and one Ross switch. The pre 1991 Gargraves switches seem to work fine for diesels and most cars, but on occasion some steamers and lighter cars will derail when reversing or when taking the diverging track. I have had no problems with the new style Gargraves switches or the Ross switch. I have considered replacing some of the pre 1991 Gargraves switches with new Gargraves 100” R which are a bit longer than the old ones or with Ross 100/101 which are an exact match.

Hi Mike

In your pic above did you use a spade connector or twisted wire to join (solder) into the bottom rail? And do you always use connectors on both outside rails as your ground?

Tks

Tommy

PS: I need to get to you about feral bees along the Montour Bike Trail.

Is the Stainless Flex Track harder to work with? Nope

Are there any special tools or hardware exclusive to working with Stainless track? In the style of Austin Powers, I use my belly to bend it.

What is the minimum curve you can bend it to? I keep a piece of 072 sectional track handy. It is used to ensure that my curves are no tighter than 072.

To cut it, I use this saw from Harbor Freight.

I also use the saw from Harbor Freight

Doug

I posted this on another forum concentrated on Gargraves derailments, especially with their early switches. All my stuff dates from the 80s. You can make switches more reliable by installing longer guard rails (I actually use Gargraves rail), and by using a Dremel cone grinder tool to grind a small cavity in the main rail where the switch rails make contact, so they are flush with the outer rail, like Lionel tubular switches.