Does it make any difference as to the positions of the working linkage on the right side vs the left side of the engines?

Replies sorted oldest to newest

The wheels hav to be quartered which affects the linkage. Let the experts explain.

Does it make any difference as to the positions of the working linkage on the right side vs the left side of the engines?

On most Lionel engines, the answer is no, so long as all the wheels on one side are in the same relative position.

On Postwar Lionel generals, the wheels must be set the same on both sides because the side rods connect to a single piece that slides back and forth. I believe Modern Era Generals are constructed the same way, but I am not familiar with every model they released.

Tommy posted:Does it make any difference as to the positions of the working linkage on the right side vs the left side of the engines?

Is this a model railroad/toy trains question?

No. A real trains question. But the model answer was interesting.

Tommy posted:No. A real trains question. But the model answer was interesting.

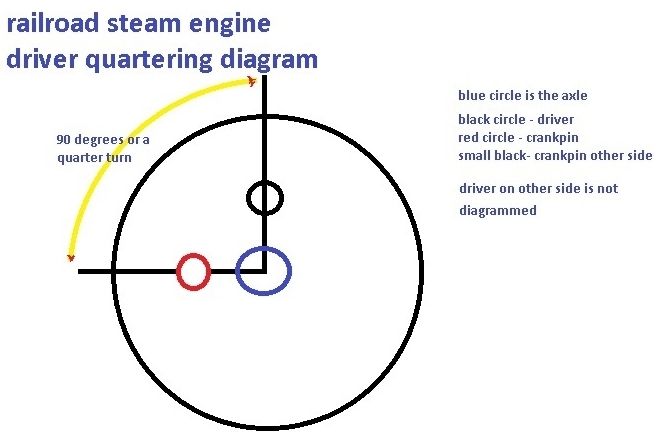

OK than. The main rod and side rods on a real steam locomotive MUST be "quartered" at 90 degrees apart, from the right side to the left side. That is a design requirement in order to have a power stroke every 90 degrees of drive wheel revolution. The cylinders are doubling acting, so that the pistons receive steam, and thus "push" on both directions. That is why there are four evenly spaced exhausts (chugs) per every 360 degrees of drive wheel rotation.

I could be wrong here, but I would've thought the poster's question had more to do with the angle of the valve gear eccentric crank on the main driver.

Angled to the right of driver center? To the left? By how much? Different/same angle direction for right and left sides? etc., etc., etc..

I knew the answer many moons ago, but even I could use a refresher course on this one.

KD

DKDKRD,

I didn't think that was his question but, a good rule of thumb for the eccentric crank is: with the dos on bottom center, i.e. with the drive wheel crank-pins at exactly bottom dead center, the eccentric cranks is generally angled forward approximately 12 to 15 degrees. The eccentric crank is NOT adjustable.

What does quartered mean?

toddstrick posted:What does quartered mean?

Cut a pie into 4 pieces, what does each piece of pie equal? Or,,,,,,think of a circle, 360 degrees, cut into four 90 degree sections, i.e. "quartered".

toddstrick posted:What does quartered mean?

Think of the crankpins like the pedals on a bike. If you've ever tried to start a bike with the pedals in an "up and down" position, by applying pressure straight down on the top pedal, you wouldn't be able to start the bike. With the crankpins set at 90 degrees, either one piston or the other would be applying revolutionary force at any point in the wheel's revolution (well, *almost* any point).

toddstrick posted:What does quartered mean?

in this case "quartering" means "lying at right angles".

when you "quater" a wheel, the plane of the wheel tread is at a right angle to the axle.

cheers...gary

overlandflyer posted:when you "quater" a wheel, the plane of the wheel tread is at a right angle to the axle.

Huh?

What the heck is "the plane of the wheel tread?"

overlandflyer posted:toddstrick posted:What does quartered mean?

in this case "quartering" means "lying at right angles".

when you "quater" a wheel, the plane of the wheel tread is at a right angle to the axle.

cheers...gary

Some how, I don't think THAT information will help.

Hot Water posted:overlandflyer posted:toddstrick posted:What does quartered mean?

in this case "quartering" means "lying at right angles".

when you "quater" a wheel, the plane of the wheel tread is at a right angle to the axle.

cheers...gary

Some how, I don't think THAT information will help.

it may not help, but quartering wheels has nothing to do with valve gear timing. any wheel can be quartered on any axle. to put it more simply, if wheels aren't quartered properly, the wheelset will wobble.

cheers...gary

overlandflyer posted:it may not help, but quartering wheels has nothing to do with valve gear timing. any wheel can be quartered on any axle. to put it more simply, if wheels aren't quartered properly, the wheelset will wobble.

cheers...gary

No one said quartering had anything to do with valve gear timing.

That's simply untrue about "any" wheel can be quartered. When talking about quartering, we're talking about the placement of the crankpins, not anything specific to the wheel itself.

I think you need to study a bit more about what wheel quartering means when talking about a steam locomotive.

It sounds like what you're trying to say is that the wheel center needs to be placed on the axle squarely. This has nothing to do with quartering.

overlandflyer posted:Hot Water posted:overlandflyer posted:toddstrick posted:What does quartered mean?

in this case "quartering" means "lying at right angles".

when you "quater" a wheel, the plane of the wheel tread is at a right angle to the axle.

cheers...gary

Some how, I don't think THAT information will help.

it may not help, but quartering wheels has nothing to do with valve gear timing. any wheel can be quartered on any axle. to put it more simply, if wheels aren't quartered properly, the wheelset will wobble.

cheers...gary

May I suggest you find, and read, the International Correspondence Courses on Steam Locomotive running gear machinery, quartering, and valve timing.

Hot Water posted:May I suggest you find, and read, the International Correspondence Courses on Steam Locomotive running gear machinery, quartering, and valve timing.

Definitely an excellent suggestion!

The drivers on the right side are a quarter turn from the drivers on the left.

Throw in "Direct" & "Indirect" motion and really confuse 'em!

Big Jim posted:Throw in "Direct" & "Indirect" motion and really confuse 'em!

Not to mention "right hand lead" and "left hand lead".

It's not "linkage."

It's called "Valve Gear."

That was fun. Some valve gear parts are called "links", so maybe "linkage" isn't that far off. But the "quatering" discussion was fascinating. I shall have to look that one up. "Quartering" on the other hand, is also essential to avoid side rod lock-up, in addition to providing a power stroke every 90 degrees.

I looked it up - no such word.

Maybe Gary was confusing "Square" with "Quarter"? To me, no wobble would mean a wheelset was "square" - but to real railroaders a square wheel might be one with flat spots?

Interesting answers. Thanx.

bob2 posted:...Some valve gear parts are called "links", so maybe "linkage" isn't that far off...

There are "links" in the valve gear, but the whole assembly is called the "valve gear."

bob2 posted:"Quartering" on the other hand, is also essential to avoid side rod lock-up, in addition to providing a power stroke every 90 degrees.

Not true. The crankpins can be placed at 180 degrees, or even 0 degrees apart from each other, and the wheels won't "lock up." Quartering is purely done so that power can be applied throughout the entire wheel revolution.

During each piston stoke in a double-acting steam cylinder, there is a point in the power cycle where both steam admission ports are closed. This position is called "on center." Since both steam admission ports are closed, no steam can enter the cylinder and nothing happens.

If the crankpins were 180 degrees apart, it would be possible for the locomotive to stop with BOTH sides on center! In that situation, you could open the throttle all the way and the loco would not move. Quartering the crankpins 90 degrees apart insures that the locomotive cannot be stopped with both cylinders on center.

Quartering has nothing to do with side rod lockup. All it does is make sure the locomotive can't stop with both sides on center.

Steam engines of all kinds-stationary, marine, railroad and even automotive are a fascinating study in mechanical design. Done without computers.

See how the outside siderods don't run exactly in sync in this animation. That's because the driving wheels on one side of the standard 2-cylinder locomotive are 90 degrees ahead of the wheels on the other, (i.e. "quartered" to achieve the results explained by Webmaster Rich above. (Ignore the inner cylinders for now, as it's a four-cylinder engine example.)

Nice illustration. the drivers also act as a flywheel to smooth things out between strokes.

If anyone owns a postwar Lionel engine with spur gears, like a 224E, you can manually experience the effect of quartering. Holding the engine upside down in your hands, use your thumbs to push and pull the crosshead guide. You will see that you need to "push, push, pull, pull" in order to get the wheels to rotate completely.

The angle of an eccentric crank depends on the setting of a valve. The most familiar is a "direct" setting for an "inside admission" valve. Steam flows between the steam chest and the cylinder at the inner faces of a valve. The crank is to the right of a driving axle when the rods are low

Older locomotives like this East Broad Top 2-8-2 have "outside emission" slide valves. Steam flows between the steam chest and the cylinder at the outer faces of the valve. These cranks are to the right of a driving axle when rods are high. They would be to the left (behind) a driving axle when rods are low.

Attachments

Big Jim mentioned "Direct" and "Indirect" motion. In the late 1920's, "indirect" Walschaerts valve gear was popular on the B&M, SP and UP. The eccentric crank was set to the left (behind) a driving axle when rods were low. A radius rod was moved to the upper part of a reverse yoke to go forward and to the lower part to go backward - just the opposite of "Direct" setting.

Come to think of it, SP Cab-Forwards had "Indirect" Walschaerts valve gear. "Back Up" was actually "Forward" on these locomotives. Photos of 4294 in the California State Railroad Museum reveal that. Look closely at eccentric cranks and valve gear.

Firewood posted:See how the outside siderods don't run exactly in sync in this animation. That's because the driving wheels on one side of the standard 2-cylinder locomotive are 90 degrees ahead of the wheels on the other, (i.e. "quartered" to achieve the results explained by Webmaster Rich above. (Ignore the inner cylinders for now, as it's a four-cylinder engine example.)

This is a really cool video, although I prefer to watch it at quarter-speed. The cylinders on each side are 180-degrees apart, so one set of valve gear serves both with just a crank-rod to reverse the motion to the inside cylinder on the same side. But the wheel balance weights don't look right for a four-cylinder arrangement.

ReadingFan posted:Come to think of it, SP Cab-Forwards had "Indirect" Walschaerts valve gear. "Back Up" was actually "Forward" on these locomotives. Photos of 4294 in the California State Railroad Museum reveal that. Look closely at eccentric cranks and valve gear.

One thing to notice is that if the gear is direct in forward, it is indirect in reverse. If it is indirect in forward, it is direct in reverse.

Is the "reach rod" the "Johnson bar"?

Tommy posted:Is the "reach rod" the "Johnson bar"?

No, the "Johnson Bar" is in the locomotive cab and that is lever that the engineer moves. The "Reach Rod" is connected to this lever (see below).