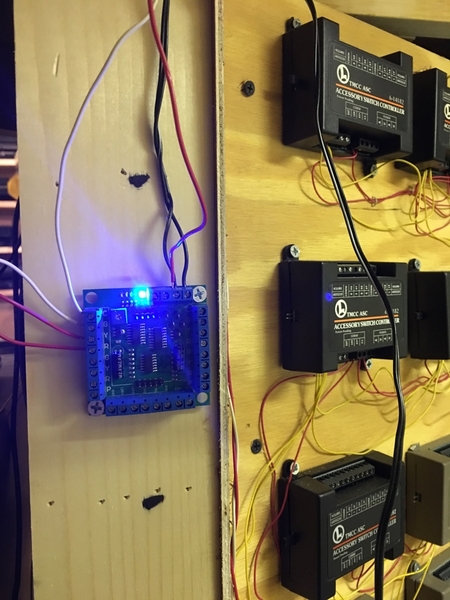

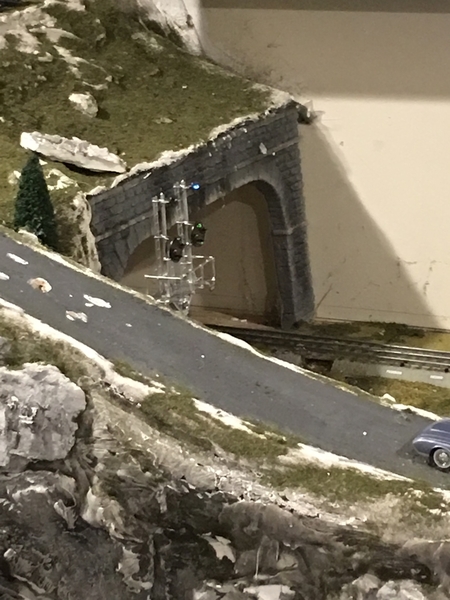

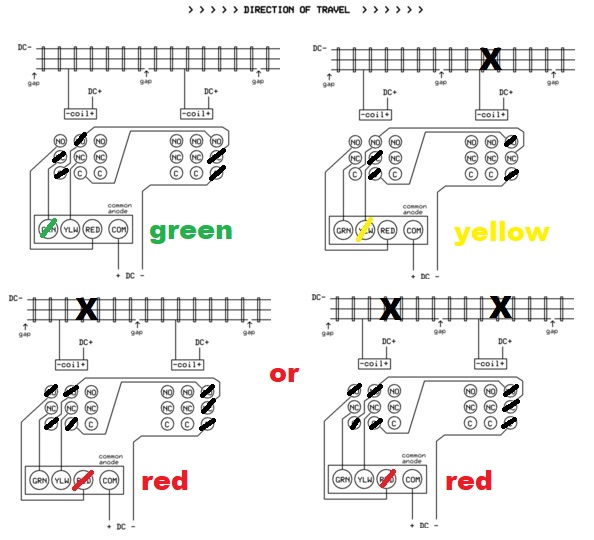

All this is great stuff, and I'm sure would be super cool to have running. However, I think there's a large audience that just wants some basic signal capability at low cost. That's what I was trying to address. If you want to spend more money, there are tons of commercial offerings that already do a lot of this stuff. I'm seeing a DIY solution that can be assembled for a few bucks and offer basic signal functionality with a handful of "nice to have" options. If the build cost goes much over $10, the project goes way off track.

A good idea that came out of the discussion is to have the board support going a more complex route, but have the option of assembling a simple signaling system by simply leaving parts off. As far as programming the Arduino, the same thought applies. I'm visualizing a simple signaling system being first implemented and then the community has the option of expanding it and using the extra capability that is built into the board. It's a building block approach, not an all-in-one solution right out of the gate.