I know there is a lot of driveline experience on this board, hopefully some of you will share with me...

Many recent die-cast steam locos have the gearbox cast into the chassis, which is less than ideal for a number of reasons. However it does solve an otherwise vexing problem: since the bearings for the worm are clamped firmly to the chassis, the worm shaft and axle gear can't squirm, wiggle, or cock backwards due to reaction torque under load.

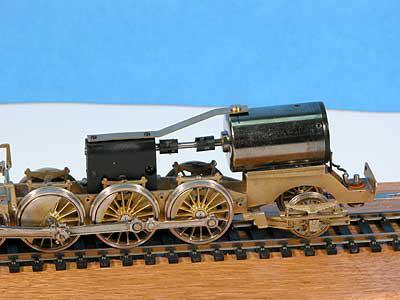

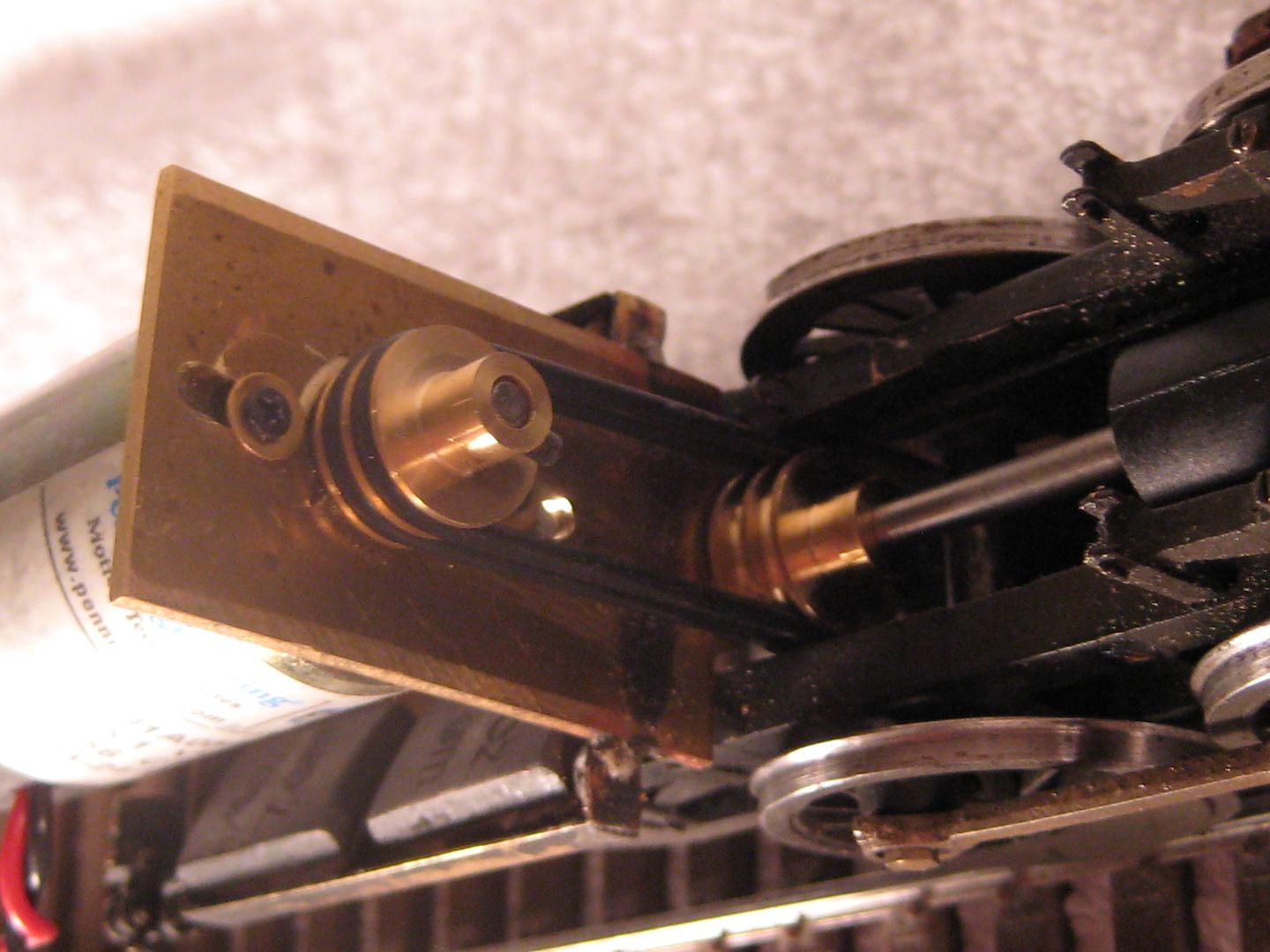

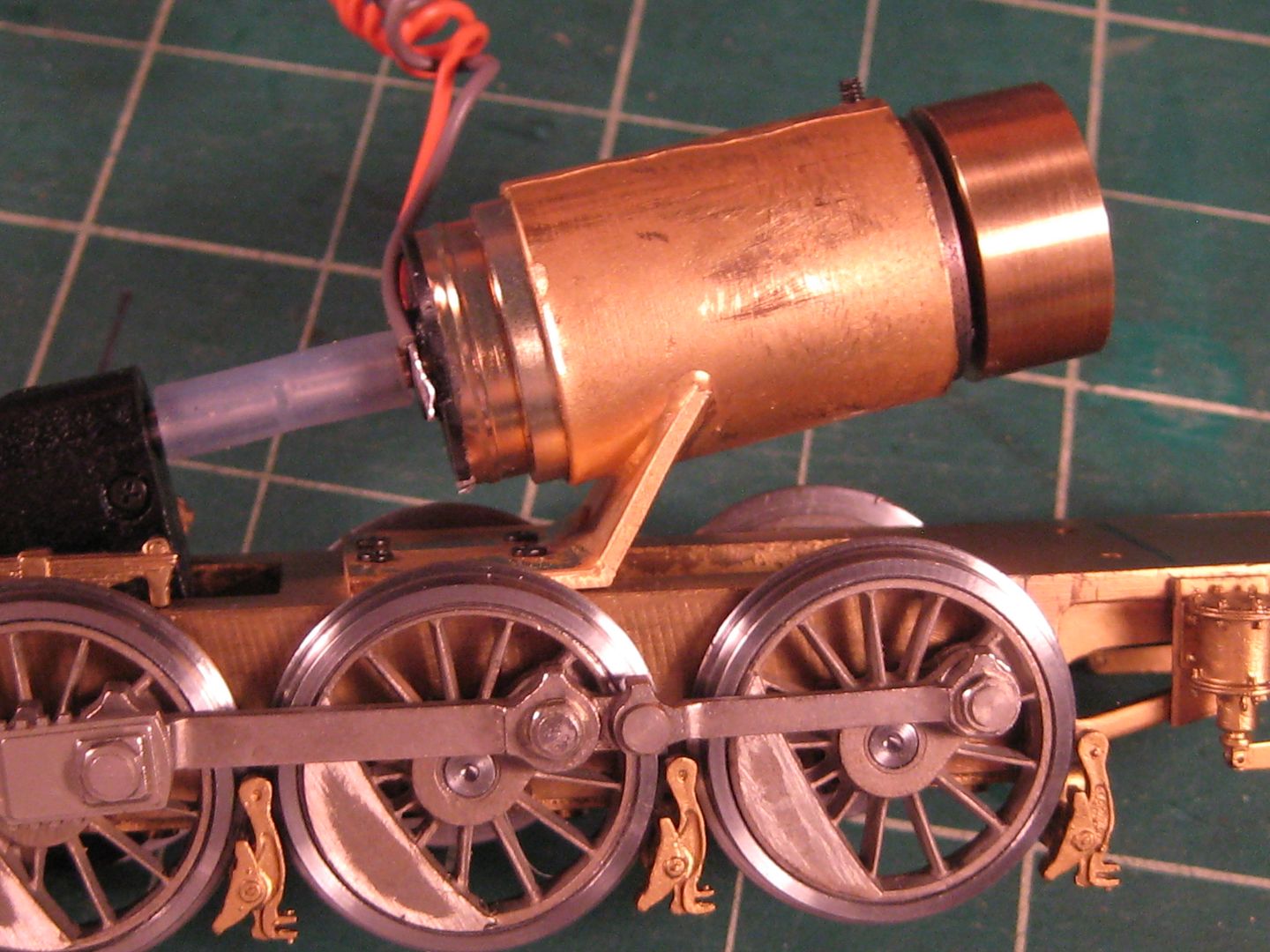

A separate KTM-style or NWSL gearbox is vulnerable to all of these phenomena, which might adversely affect operation. Also, depending on how the motor shaft is connected to the worm shaft, movement of the gearbox could place an unwanted load on the motor's bearings. The installation I'm contemplating won't be sprung, so there is no need to accommodate vertical motion. So it seems like the best solution would be to add a torque brace, firmly attaching the gearbox to the chassis and thus preventing any unwanted movement.

The NWSL gearboxes I'm familiar with (0.5 or 0.6 mod) do not appear to include a torque brace in the kit, or even have mounting holes for one. For those of you who have used one of these on a scratch-built steam loco, how do you prevent the gearbox from rotating back toward the motor? And if you use a torque brace, where do you attach it to the gearbox?

Any photos / sketches would be most helpful. Thanks!