Thanks Dave,

Weathering: So the Jade Green NYC Boxcar and the NKP black covered hoppers were dull coated then I applied Pan Pastels, and then sealed them with another coat of Dullcoat. All the brown, red oxide Metal & Single Sheathed Woodside 50 foot Auto boxcars were done with acrylic washes. The only exception was 50 foot CB&Q - Burlington Dbl Door Single sheathed Automobile boxcar which I did with an oil base wash. It worked really well, but it takes more than a day to dry, and I don't have much of the patience gene...

As the weather's been all over the place and I didn't want to dull coat one or two car, I decided to rough up the surface of the Santa Fe 40 ft PS-1, and the B & O Wagon Top boxcars with 0000 Steel wool (SuperFine).... It actually worked really well, knocked down the bright white lettering took off the high gloss and left a surface that was easy to apply acrylic wash over. I was anxious to do these two as I already had a wash made up for the 50 foot Santa Fe Woodside Boxcar...

Not sure when I started doing this, but on some areas I sprinkle one or more of the Pan Pastel colors and blend it with the acrylic wash while it's wet. It makes decent rust spots, just don't over blend it. Leaves a texture. I usually use a still short brush to pick up the pastel powder, then tap it to drop the powder as close to where I want it...

Last technique but not least, is I use watercolor pencils to vary the color of a few boards on the woodside cars, easy to control where the color goes. then put the wash over it.

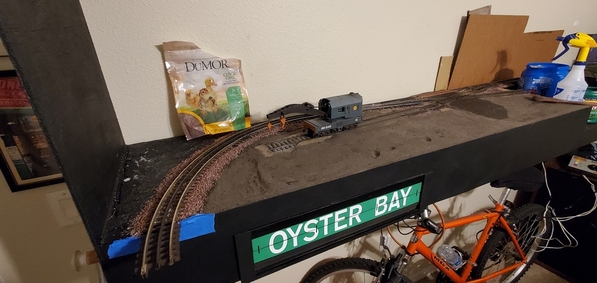

Bob, to answer your question, I was pleasantly surprised at the condition of the track and the layout. Ever since I started cleaning the track with mineral spirits instead of all the other choices, and using the NO-OX - ID Electrical conducting anti-oxidant formula on the blackened center rail, I don't get the awful black buildup on the rails. It probably helps that everyone of the 40 or so cars that I have converted to Kadees in the last 2 years, gets a "thorough" wheel cleaning with mineral spirits during the conversion. I had quite a few cars that had the "mysterious" black build up on the wheels. Yes I probably should have vacuumed, but not too many "cobwebs". Deciding to "dust" this layout is a serious commitment.

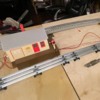

Hey Mike G: I like the use of the Flex Track, looks great and makes things run smooth... chris