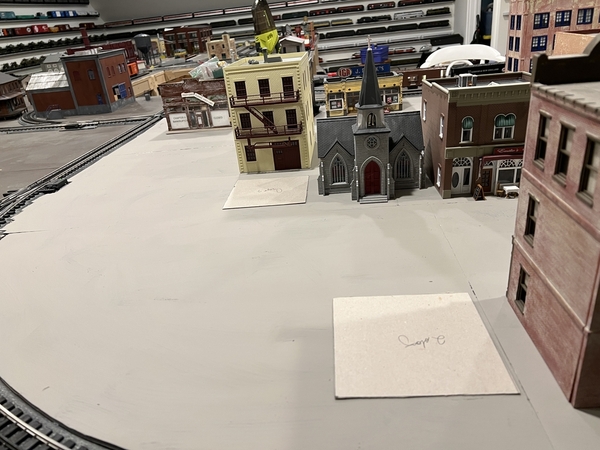

The fronts looks good Chris. Looks like you have room for full buildings, why just fronts?

Bob

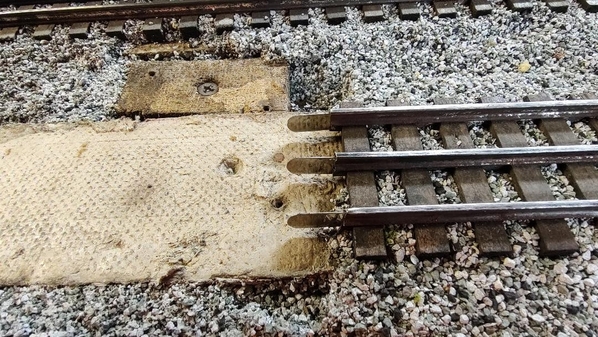

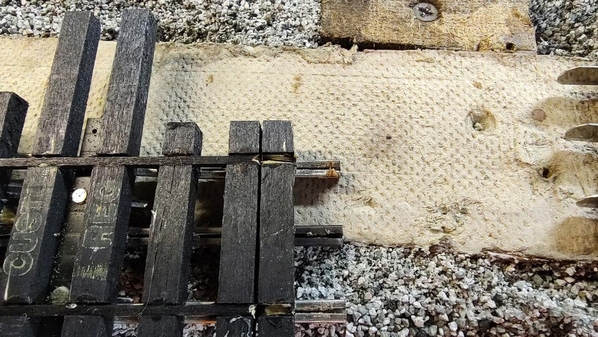

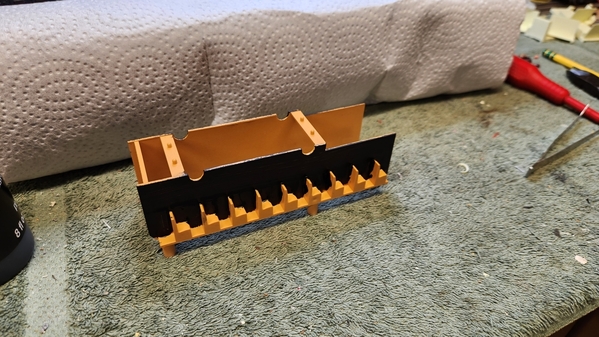

Bob, my current thought process is that I will end up grouping a number of these fronts together and then just adding side and back walls to the group. I can save a bunch of side walls by not using 2 of them them with each individual front wall. If I need to "divide" them I'll just add some 1/8 inch hardboard, or something cheap and readily available to create a dividing wall. It's also not clear at this point, that based on the sidings running through the area that all building foot prints will be conventional squares or rectangles. I reasonably sure that the back walls may follow the path of the "street" which could very well be following the curve of the siding track as it winds through the district.

As I have been driving around looking at these types of buildings near where I live, it seems that most of them have different brick on the side and rear walls. From a little reading and research, it appears that it was pretty standard practice to use a less expensive brick on the side and rear walls and it was usually just a "standard cost effective monotone brick red" variety.

So, once I figure out the overall urban building layout, my plan is to figure out a much quicker way to just come up with a simpler less detailed weathering process to color and weather the side and rear walls and finalize this whole area.

I am fairly close to finding a quicker weathering method with probably only two colors to give me a back and sidewall that doesn't look like plain old red plastic with mortar, but won't take the painting and weathering time that these front walls are demanding.