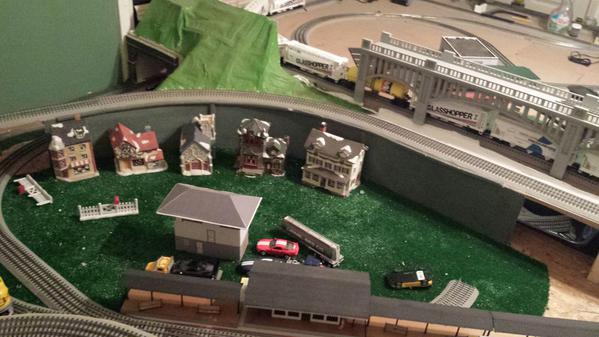

Laidoffsick knows how to build a layout! I mean d@mn!

Ordered some 072 curves from Ross today... tomorrow start on new benchwork.

Ordered some 072 curves from Ross today... tomorrow start on new benchwork.

Congratulations!!

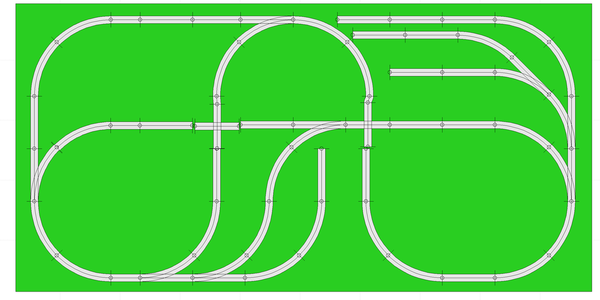

The entire weekend pretty much was dedicated to layout construction. Building a layout in sections has an advantage and a disadvantage to building it new in a room as you do. The advantage is if something screws up, you don't have much to fix. The disadvantage is you have no idea what it'll look like until you get it all together.

And only once I laid the sections out on the ground and measured them did I realize, this simply isn't going to work. The center 'U' shape section is simply way too big and takes up nearly all the space in the center of the room. There's just no room to move around at all.

Better to find out now, but it was really annoying to know that the hardest part of the build is the one part I probably can't use any part of.

So, right away I realized the best thing to do is to just have the center section come into the center of the room at a 45 degree angle and stop there. It'll give so much more space to move around in. I'll lose some track, but it's better to realize that now.

I was totally worn out and thought I was done Sunday evening. Nope, I'm going to have to build a totally new center portion. I hope I can salvage a lot of the 1X4s from the center section, thankfully I have a large sheet of plywood from the build, and plenty of screws, nails and hardware.

One image shows it laid out, the other is a photoshopped version I took later showing roughly what it's going to have to look like.

Needless to say, I was almost crushed at the realization it wasn't going to work. But at least the newer version won't be nearly as tough to build as this one section was...

The entire weekend pretty much was dedicated to layout construction. Building a layout in sections has an advantage and a disadvantage to building it new in a room as you do. The advantage is if something screws up, you don't have much to fix. The disadvantage is you have no idea what it'll look like until you get it all together.

And only once I laid the sections out on the ground and measured them did I realize, this simply isn't going to work. The center 'U' shape section is simply way too big and takes up nearly all the space in the center of the room. There's just no room to move around at all.

Better to find out now, but it was really annoying to know that the hardest part of the build is the one part I probably can't use any part of.

So, right away I realized the best thing to do is to just have the center section come into the center of the room at a 45 degree angle and stop there. It'll give so much more space to move around in. I'll lose some track, but it's better to realize that now.

I was totally worn out and thought I was done Sunday evening. Nope, I'm going to have to build a totally new center portion. I hope I can salvage a lot of the 1X4s from the center section, thankfully I have a large sheet of plywood from the build, and plenty of screws, nails and hardware.

One image shows it laid out, the other is a photoshopped version I took later showing roughly what it's going to have to look like.

Needless to say, I was almost crushed at the realization it wasn't going to work. But at least the newer version won't be nearly as tough to build as this one section was...

I am sorry your plan won't work as designed. Yes it is better to find out right now. I will have a similar problem when I design my layout; trying to put something in the center of the room, but leaving enough room to get around.

I'm not putting the blame on the guy who made the track plan for me, as I didn't tell him there are book cases and dressers along the walls of the room (they house my books and contain my collections of WW2 and RR stuff) that take up more space into the room than he was aware of. I made the 'along the wall' sections slightly thicker because it made no sense to me to have the other stuff stick out from under the benchwork. Might as well put trains in that space as you can't stand there anyway, right?

I really should have stopped and thought about that center section. I don't think that was ever going to work well even if it did fit okay.

At least it was only one part, but that took several hours to build, and now it’s all for nothing. I thought this plan was overly ambitious, but I guess I so badly wanted it to work anyway. I see that I was deluded now that I look back on it. That said, everything else along the walls should work fine.

In a way, I’m sort of hopeful for that center section. If it’s a section about 20-24" wide and just long enough to get into the center of the room to allow freedom of movement, it’ll open up the room a lot and I can use the back side of that section for a hidden staging track. I've always wanted to have a hidden staging area anyway. I’m now thinking I’ll reverse the flow of traffic (that center section was supposed to be the end of the line) and have the interchange with the main in the center of the room now, and the end of the line will be to the upper right corner in that old track plan.

I’m really bummed about having to build more, yet hopeful at the same time. At least I found out now instead of after it was totally complete with track, wiring and scenery.

It's not like the timeframe for the layout is pushed that far back anyway. The guy who desgined the initial track plan has volunteered to help me lay track and do all the wiring (he says he has all the stuff for the wiring, has done it before on other layouts and his own layout runs really well with DCC). He's out of town until a week from today, so nothing much was going to happen even if everything came together yesterday. Maybe I can get a new concept for that center section, get the benchwork made for that and really have it all ready for track and wires in the same timeframe as before!

Fingers crossed.

The last of the sheetrock is up, next is the floor trim and the dropped ceiling. The second coat of the floor paint and we are done with basement construction. By the end of next month the layout will commence. Normally I would celebrate with a bottel of old Royal Crown but not this time, I do not want a hang over stopping the beginning of the first phase of the layout one second.

Right now I am sitting out by the fire pit, having a good cigar and a fine scotch while working on my layout plans. Deconstruction starts tomorrow on the old layout as I am staring to sell most of my Fastrack.

Attachments

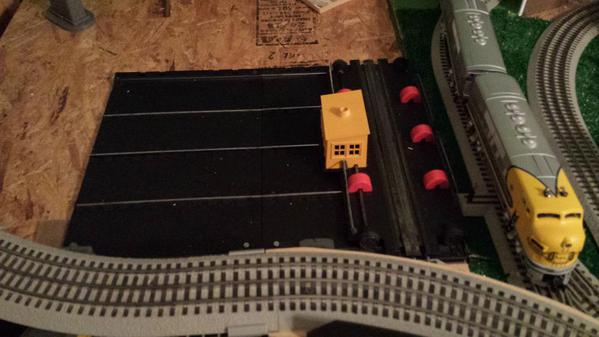

I got a 350 transfer table today so I spent the day cleaning it up and just finished testing it out drove a gp20 on and off of it via fastrack now just need to make a few custom pieces of fastrack so that thhe center roller doesn't fall in between the table and the track or I could use the transition piece I bought. but I would rather use fastback for the whole thing. the thing is louder than I thought it would be. 2 pieces of Masonite under the track puts it real close to the same height as the table. I have some 1/4 mdf I might try that too.

Tree's... tree's and more tree's... I have been making tree's while i have been saving up to pay for the lumber to start my benchwork. Thanks again to everyone that has posted pictures of their benchwork, and those that have written me back with info. I really appreciate the help!

Matt was over on Sunday, and went through another batch of engines. He's going to order some parts and some ERR boards so we can convert a few Rail Kings to TMCC. While he was working on that, I assembled electrical boxes and light sockets.

Jon came over today, and we ran power to the upper deck, then piped and wired half a dozen lights.

The conduit goes down through the lower backdrop...

then across

to the junction box.

Our afternoon's efforts.

Next time we'll work on setting up the track lighting, which will cover the other side of the aisle.

Attachments

adapted fastrack to a lionel transfer table. did a little scenery over the weekend I never showed. wired up the transfer table to a aiu . tested it and it works fine just real loud is that common? the open ends of the track are just there for fillers once I get some bumpers they will come out plus there will be a piece of mdf on the side as a fascia with a lip to keep the engines from jumping off the table.

Attachments

Tree's... tree's and more tree's... I have been making tree's ..

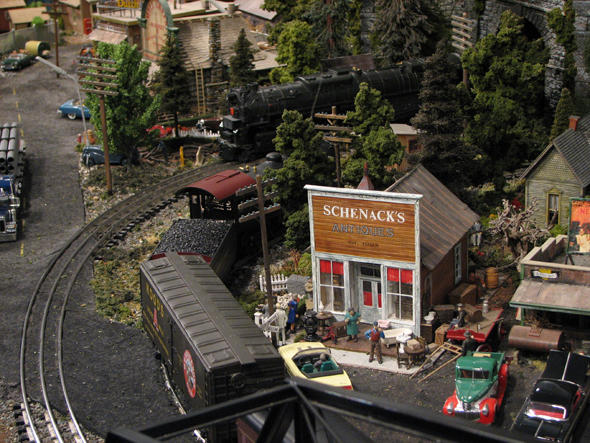

It's good to hear somebody else enthusiastic about trees on layouts. I feel they add immeasurably to the overall effect. Perhaps, you will agree with me on how I have used them and find some ideas here, Nateao, among these shots of my layout, Moon Township.

Attachments

Tree's... tree's and more tree's... I have been making tree's while i have been saving up to pay for the lumber to start my benchwork. Thanks again to everyone that has posted pictures of their benchwork, and those that have written me back with info. I really appreciate the help!

Tree's... tree's and more tree's... I have been making tree's ..

It's good to hear somebody else enthusiastic about trees on layouts. I feel they add immeasurably to the overall effect. Perhaps, you will agree with me on how I have used them and find some ideas here, Nateao, among these shots of my layout, Moon Township.

Nate,

I agree with Moonson, unless one is modeling the desert, you can't have enough trees. As shown, the occasional dead tree really adds to the realism. Thanks for the great photos, Moonson!

Tree's... tree's and more tree's... I have been making tree's ..

It's good to hear somebody else enthusiastic about trees on layouts. I feel they add immeasurably to the overall effect. Perhaps, you will agree with me on how I have used them and find some ideas here, Nateao, among these shots of my layout, Moon Township.

What a beautiful layout and GREAT trees.

I have to agree that trees probably add the most to our scenery efforts. It's amazing how much better the layout looks with them.

Moonson yours layout is beautiful!

Art

Moonson: Gorgeous scenery, there! ![]()

I have a couple of Lionel 105 bridge approaches that were knocking about not doing anything in particular, so I masked off the roadbed and resprayed them to match a Lionel 270 I also had knocking about not doing anything in particular:

Also, the latest addition to the Razorback Traction Co. fleet is this Bowser Birney which showed up sans trolley poles. A bit of work with a micro drill bit, and I adapted a pair of K-Line/Lionel poles to the Bowser bases! Also refined the battery powered Lionel 57 streetlight I'm modifying for a chum to include an on/off switch...and, as always, where there's a streetlight, there's Princess Daphne. ;-)

Photo submitted without further comment. ;-)

Mitch

Mark, Chugman, Laidoffsick, & M.Mitchell, I much appreciate![]() what each of you said. I am especially grateful for the enthusiastic words you each used. It's gratifying to share efforts and ideas with my peers in this hobby and find that I've received their approval. Thank you very much.

what each of you said. I am especially grateful for the enthusiastic words you each used. It's gratifying to share efforts and ideas with my peers in this hobby and find that I've received their approval. Thank you very much.

FrankM

FINISHED MY BENCHWORK!

And, by jiminy, it worked.

We painted the legs tonight, just needs to drill some holes to run carriage bolts between each gap to keep the sections joined together, installed into the toy room, then track laying and wiring can finally start.

Attachments

Bravissimo! Nicely resprayed. :-D

Mitch

FINISHED MY BENCHWORK!

And, by jiminy, it worked.

We painted the legs tonight, just needs to drill some holes to run carriage bolts between each gap to keep the sections joined together, installed into the toy room, then track laying and wiring can finally start.

Lee,

I'm glad to see you got your problems worked out with the center section. Looks like you have made great progress. I may have missed this, but what are your reasons for setting it up outside? Did you do your construction outside to keep down dust? I just wondered because I have never done that, but may for my future layout. However, in we have had a lot of rainy days in Western Pennsylvania this summer.

Nothing spectacular. Started detailing my Atlas SP C-30-6 Bayside window caboose from steam era to diesel. Next upgrade will be adding the frog eyes, radio antenna, and painting the bay window rear/front panel orange per 1961 SP safety upgrade.( I still have to make the frog eyes). Simple project. Hopefully I can have my CB&Q waycar project finished this week.

Attachments

it's real simple 1/2 MDF and t w trainworks elevated system

it's real simple 1/2 MDF and t w trainworks elevated system

I guess what I should of asked was what was used for the bridge sides and where did you find it?

Matt and Jon came over today. As promised, here are pictures...

Here Matt is converting a Railking switcher to TMCC. He also did a second engine, but still needs to test it.

While he was doing that, Jon and I got a bunch of the track lighting hung.

The lighting in this aisle is now 100% complete. The track fixtures may look a little goofy, but they are a perfect fit, allowing the lights to hang down just below the soffit.

It's fun bending conduit.

This aisle would be finished too, except we ran out of light bulbs. These are the Cree daylight, 60W equivalent, dim-able LED's. They only use 9W each and give off very little heat. The only drawback is they are kind of pricey. In the end, the whole lighting system will cost a little more than the VL Big Boy, but I'm happy with my choice to do this instead.

Here is part of what I was working on the last couple days. The mainline track centers are now done all the way around the next curve at the far end of the peninsula.

I would say we are about half way through the track lighting. The remainder should go fairly quickly. BTW, all the track and fixtures are recycled from enterTRAINment, 21 years ago.![]()

Attachments

Dont let all that open real estate on the work bench fool you, it didnt look anything like that until I started working there

Dont let all that open real estate on the work bench fool you, it didnt look anything like that until I started working there

Yes, well now that you've had your moment in the sun, I'm taking it back!![]() I need to repair all those switches, and I'd like to get that second set of Williams Superliners converted to LED's. That'll help clear the decks.

I need to repair all those switches, and I'd like to get that second set of Williams Superliners converted to LED's. That'll help clear the decks.![]()

Dont go messing up my workbench there PigPen, I'm gonna need open space to work magic

Thanks! I used 1/16 in. 3m auto pinstriping tape. I bought it straight off the 3m website. I got the idea from Lee Willis I think.

FINISHED MY BENCHWORK!

Lee,

I'm glad to see you got your problems worked out with the center section. Looks like you have made great progress. I may have missed this, but what are your reasons for setting it up outside? Did you do your construction outside to keep down dust? I just wondered because I have never done that, but may for my future layout. However, in we have had a lot of rainy days in Western Pennsylvania this summer.

My layout will be in a finished room with my collection of WW2 and RR stuff. It's not an empty space you can haul lumber and saws into. It's also a relatively smaller room, about 10X11 feet. The layout will be On30. Most of the structures, almost all the rolling stock and boxes of detail components have long been built and are just waiting to be placed into where they were intended.

I built the layout in 4 sections. They'll be bolted together betwene sections with two carriage bolts at each seam, after they're placed into the room. Then, track will be laid over top of that, and scenery placed over that as it's it's one large structure. The wiring with have plugs at each seam.

Why, you may ask? This is just in case we ever have to move. All I'd have to do would be to cut through the scenery with a knife or saw, snip the rails, yank out the bolts and unplug the wiring to take it out of the room. Even the legs are held into their sockets with bolts. I pretyt much built it as a module display that never moves.

I've seen too many heartbroken people having to destroy their layouts when they've moved. While I don't anticipate that happening (at least for 5-10 years the way things are going for my employer), I don't want to risk it. Sure, I could still destroy it if I wanna start over, but I'd rather have the option. It was built with 1X4 and thin plywood (the blue point switch machines will be anchored with thicker wood under the points as needed). The scenery forms will be using a new technique I've read about in MR magazine last year using towels impregnated with caulk and formed into shapes. It'll be sturdy, durable, but light.

if you click my link below, you'll see more on the concept and progress...

FINISHED MY BENCHWORK!

Lee,

I'm glad to see you got your problems worked out with the center section. Looks like you have made great progress. I may have missed this, but what are your reasons for setting it up outside? Did you do your construction outside to keep down dust? I just wondered because I have never done that, but may for my future layout. However, in we have had a lot of rainy days in Western Pennsylvania this summer.

My layout will be in a finished room with my collection of WW2 and RR stuff. It's not an empty space you can haul lumber and saws into. It's also a relatively smaller room, about 10X11 feet. The layout will be On30. Most of the structures, almost all the rolling stock and boxes of detail components have long been built and are just waiting to be placed into where they were intended.

I built the layout in 4 sections. They'll be bolted together betwene sections with two carriage bolts at each seam, after they're placed into the room. Then, track will be laid over top of that, and scenery placed over that as it's it's one large structure. The wiring with have plugs at each seam.

Why, you may ask? This is just in case we ever have to move. All I'd have to do would be to cut through the scenery with a knife or saw, snip the rails, yank out the bolts and unplug the wiring to take it out of the room. Even the legs are held into their sockets with bolts. I pretyt much built it as a module display that never moves.

I've seen too many heartbroken people having to destroy their layouts when they've moved. While I don't anticipate that happening (at least for 5-10 years the way things are going for my employer), I don't want to risk it. Sure, I could still destroy it if I wanna start over, but I'd rather have the option. It was built with 1X4 and thin plywood (the blue point switch machines will be anchored with thicker wood under the points as needed). The scenery forms will be using a new technique I've read about in MR magazine last year using towels impregnated with caulk and formed into shapes. It'll be sturdy, durable, but light.

if you click my link below, you'll see more on the concept and progress...

Yes Lee, that makes sense. The reason I asked was that your scenario was another I had in mind. I may have to do the same thing. I haven't had a layout for a few years, and we live in a small house. I often have to cary things out onto the patio and set them up on the picnic table or sawhorses to work on them.

I agree with the modular build. My last layout was modular, and I moved it twice until a growing family made it expendable for the next move. While I have no desire to move again, I will build modular, because one never knows.

Thank you for your comments, and have a good time with your layout!!

I put about 40lbs of Strucolite on my bench. I covered a little more then half. It takes a few days for it to dry in a cool basement. The train room is right next to the furnace and A/C unit so the basement stays cool. So far I like the results. I was able to fill in a few gaps and taper a few other areas. The part that is dry is rock hard. I put the mesh down on the rest of the bench and made some final adjustments to the area where the double bridges will go. I still have to make the abutments for both bridges. I have two more areas that I have to make adjustments, but will need the track back on the bench for the final fitting. I'll post photo's as soon as I find the camera cord.

The new rebuild has finally begun... wood cut and the first table for roundhouse and turntable has been constructed.

FINISHED MY BENCHWORK!

And, by jiminy, it worked.

We painted the legs tonight, just needs to drill some holes to run carriage bolts between each gap to keep the sections joined together, installed into the toy room, then track laying and wiring can finally start.

Learned something new and thought Id share.

Ive always hated carriage bolts. Often, starting a nut without pushing back on an unsupported head, causes the head to unseat, and the bolt to turn with the nut, swearing begins. Especially annoying if the head is hidden from your reach. Ive seen small finishing/tack nails, e-clips on threads, and glue, all used to keep the head seated. Yesterday I saw another solution. While dismantling an old couch into 4 pieces, so it could fit into the gigantic garbage cans our city uses, I saw 3"x3" squares of thin cardboard stapled over the head, to hold the bolts in place.

My son Chris and I did some work on the upper level engine servicing facility. We cover it the bare wood with white paper in preparation for laying a snow blanket.

I drilled a hole in the top of my new Lionel tank car and poured in some BBs until it reached NMRA standard. After repairing and painting the hole I oiled the wheels and couplers. It rolls really nice.

.....

Dennis

Nothing. I am away from home and suffering withdrawal symptoms. ![]()

Me either Lee. My half is killing me with honey do's. I almost wish winter would hurry up and get here. I'm lucky just to get to read the forums for a half hour.

My half is killing me with honey do's. I almost wish winter would hurry up and get here. I'm lucky just to get to read the forums for a half hour.

My wife hit me with a substantial list of chores as well, even though I told her over the winter that this was going to be my time for a project (in 14 years of marriage, it's always been her projects, I've never taken on anything like this before). I even blew off the majority of every other annual event with my other hobbies to get my benchwork built and installed and get the layout finally going. That didn't stop her from, say, breaking out the pressure washer and annoucing that the entire side of the house needed to be pressure washed (in anticipation for painting... NEXT YEAR) after I'd broken out all my tools and was already cutting lunber. And yes, that meant me. Things got a little tense there.

As for where I am, I was having to move a short book case over about 2" to allow space for legs for one end of a long yard section to fit into place (all the sections are out in the shed, ready to install once I drill connecting holes to run bolts through to keep the sections tighly together once they're in place). That moves eveything over 2 inches, and that blocked the space for legs at the other end of the same section. So I'm going to have to toss out one book case (no problem, it was a cheap wal mart book case I'd cut down with a radial saw to fit under the bench work, something I was gonna replace anyway). But that's where all the finished structures for the layout were sitting. I've move four massive containers of stuff out of that room into the room where our computer and guest bed are. Thankfully, my wife was okay with that until I can get the bench work in place. She's become far more realistic once she's seen the benchwork 90% done and realized the true scope of what I'm doing.

I also need to buy some more containers for other stuff that needs to move out of that room as well. i hope one trip to wal mart or home depot for containers and one more cheap short book case will resolve these issues.

Once that is done, the benchwork can finally be installed. Then, track laying and wiring begins! A local pal of mine has volunteered to assist me in the track and wiring, and I'm happy for the help. I'm useless with electricity.

I tested my R-17 subway Proto 2 and another PCC proto 2 trolley NJ transit in my garage on a spare test table. I have HOney do's also. Kitchen cabinet refacing, tiling backsplash and re-paint. yikes! then Ill tackle finishing my basement and put up a layout in November. I hope!

Chris

Did some inventory of hobos on my layout (there are males and females) there are 35 at last count! Don't want them multiplying! LOL! This is a family friendly layout!

Mike Maurice

Did some inventory of hobos on my layout (there are males and females) there are 35 at last count! Don't want them multiplying! LOL! This is a family friendly layout!

Someone recently gave me a set of... not family friendly female figures, let's just say. No way those are going onto the layout. I know of a big layout locally that has a house of ill repute and the owner sometimes turns on the lights on the top floor. The shades are pulled back and you can see, well, a very R rated scene.

Yeah, that's not my bag. I don't want to have to worry about what lights I flipped on when someone comes over for an op session or my wife decides to take a look around (I'd never be able to explain that to her as she was born whimsy-impaired).

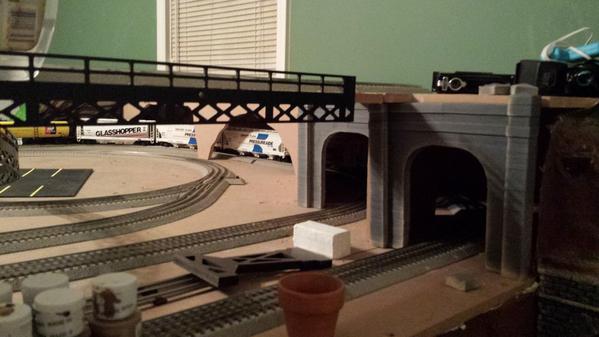

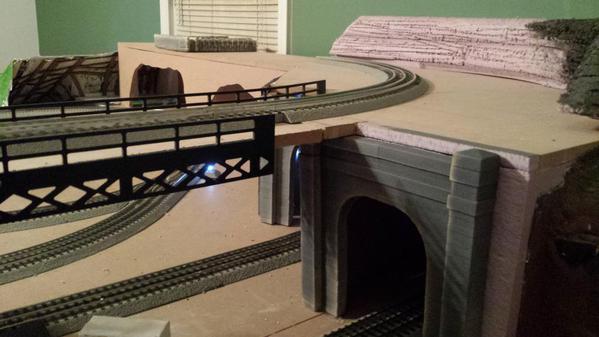

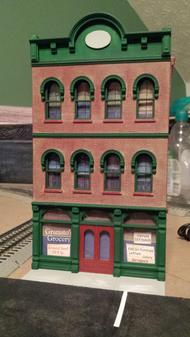

slowly working on the upper level tunnel. also picked up 5 ameritown 3 story buildings and the furniture factory. still waiting for my bumpers to show up so I can finish wiring the sidings off of the transfer table. didn't want to run power to the sidings and have a train try to jump to the floor.

Attachments

Tree's... tree's and more tree's... I have been making tree's ..

It's good to hear somebody else enthusiastic about trees on layouts. I feel they add immeasurably to the overall effect. Perhaps, you will agree with me on how I have used them and find some ideas here, Nateao, among these shots of my layout, Moon Township.

Thanks Moonson for posting up these great pictures! Your right... the tree's totally make a Great layout that much better! Those tree's are awesome! Great Job!

Take your time, Jhanier. I am convinced the creative process is a very large part of our enjoyment of our hobby, maybe even equal to finding and buying the trains we want, running them, sitting back and enjoying possessing the whole shebang, and schmoozing with friends about all our train-related shenanigans.

You may even be sorry - though you may not be able to see or feel that just now - when the whole layout is finished (another theory I have which says the layout never is totally done but always ready for a li'l tweaking here and there, now and then.)

Enjoy.![]()

FrankM

Tree's... tree's and more tree's... I have been making tree's ..

It's good to hear somebody else enthusiastic about trees on layouts. I feel they add immeasurably to the overall effect. Perhaps, you will agree with me on how I have used them and find some ideas here, Nateao, among these shots of my layout, Moon Township....

Thanks Moonson for posting up these great pictures! Your right... the tree's totally make a Great layout that much better! Those tree's are awesome! Great Job!

Thanks, Nateao. It's good to hear from you. ![]() As you make those trees, you won't forget about the underbrush, too, will ya' .

As you make those trees, you won't forget about the underbrush, too, will ya' .![]()

FrankM/Moonson

Tree's... tree's and more tree's... I have been making tree's ..

It's good to hear somebody else enthusiastic about trees on layouts. I feel they add immeasurably to the overall effect. Perhaps, you will agree with me on how I have used them and find some ideas here, Nateao, among these shots of my layout, Moon Township.

Thanks Moonson for posting up these great pictures! Your right... the tree's totally make a Great layout that much better! Those tree's are awesome! Great Job!

I agree wholeheartedly with Nate! First, if you are modeling the East or anywhere else that has trees, a modeler can't have enough trees. Second, I agree your trees are fantastic, Moonson!

Nate, I see you were able to reply with the photos as you asked me in the e-mail. I will get back to you on that, but don't have time right now. I have to turn my attention to what my employer wants me to do today. Forty years of the boss's desires getting in the way of what I want to do. What a bummer. ![]() Oh well I get a few dollars a month to pay for trains.

Oh well I get a few dollars a month to pay for trains. ![]() See you later on the e-mail, Nate!

See you later on the e-mail, Nate!

Work continues on my on my CB&Q Way Car project. Crews primed and finished body work. Way Car temporally pulled out of the shop while waiting for parts and orange paint..

Attachments

Received a shipment of Ross 072 curve track today and the Ross WYE switch is due tomorrow.

Time to get to work!!! ![]()

Ive been working on my Korber power plant kit this week. Waiting on some MTH smoke units to get here to put in the smoke stacks. Its been almost 20 years since I built a kit and I have to say it is really quite relaxing and satisfying.

Attachments

I also spent this Saturday dismantling a developmentally delayed mans layout so the contractor can renovate his flooded basement. The poor guy was heartbroken to see his baby being taken apart. He was incredibly helpful in the work, gave me a chance to be foreman but it really was a one man job. I wish I got half as excited about anything as that man got about his train set. He will have a long couple months while the work gets done and then I can get back there and put it back together.

More wiring.........still haven't caught up to where I was in late March (when I burnt out all my Atlas switch motors).

All are replaced with DZ1000s........just taking my tine wiring them up.....there are 22 of them........then I move on to the 5 O72 tinplate switches I have in my yard.

Peter

No Jon, I bought if form a forum member. Elliot has the eagle eye and I think he would notice the vaccuum forming from something missing form his basement

Tree's... tree's and more tree's... I have been making tree's ..

It's good to hear somebody else enthusiastic about trees on layouts. I feel they add immeasurably to the overall effect. Perhaps, you will agree with me on how I have used them and find some ideas here, Nateao, among these shots of my layout, Moon Township.

Thanks Moonson for posting up these great pictures! Your right... the tree's totally make a Great layout that much better! Those tree's are awesome! Great Job!

Installed a Mianne Lift-Gate. No more crawling to get inside the layout, nor a troublesome lift out section. On to the the turntable tomorrow.

I painted much of the homasote on the layout dirt brown, Then I painted the cork roadbed a dark gray. It will be a long time , if ever, that I put in real ballast. Next I started laying track for the lower level. One 12 foot stretch will be very hard to get to when the layout is finished so I spent a lot of time getting the track as perfect as possible and screwed down tight. I put in electrical drops every 6 feet in the event power becomes a problem after several years.

Originally posted by Chris D

I use goldenrod combine and wrap with wire to create a nice tree. easy to manipulate and cut to shape. and its free! weeds in the field. Dry out and primer and then color fall and summer colors. I did winter one year with snow in a can! worked like a champ! I love trees and lots of them.

Hi Chris,

I too would like to make some homemade trees. How about a couple of pictures of your "goldenrod" trees and a brief tutorial. Would be much appreciated.

Jim

Benchwork is installed, bolted together, levelled, and track laying has already begun. I intend to have all the track work done by next weekend.

I almost couldn't handle standing in the center of it all. I've been dreaming of this for the better part of 30 years...

Lee,

I understand the feeling. I'm glad you are making good progress.

Looking good. Are you going to have enough clearence on the bridge? A curve leading into or out of the bridge will cause larger items to hit the bridge.

Looking good. Are you going to have enough clearence on the bridge? A curve leading into or out of the bridge will cause larger items to hit the bridge.

I believe you are talking to me, and that bridge isn't staying there! It was only laying there due to the riverwork going on down the line. But thanks for the heads up! I learned that lesson the hard way already by having my articulated locomotives cab's hit the bridges on the way out and into a curve.

Welcomed grandparents and grand kids to the layout and ran some trains for them. Usually this would be a fun event, but not this time. Rude comments from the adults about "how much money" and aren't you lucky I am not into this" and grabby poorly mannered kids. Not fun. Session ended quickly.

I am tearing it down. Removed all the track, it looks like the railroad pulled up the track and converted it all to Rail-Trails!

Should have it all down here soon and start on the new layout in a few short months.

Welcomed grandparents and grand kids to the layout and ran some trains for them. Usually this would be a fum event, but not this time. Rude comments from the adults about "how much money" and aren't you lucky I am not into this" and grabby poorly mannered kids. Not fun. Session ended quickly.

That is very sad some people act so rudely in spite of your hospitality. Don't let it stop you from inviting people who haven't visited before.

Looking good. Are you going to have enough clearence on the bridge? A curve leading into or out of the bridge will cause larger items to hit the bridge.

I believe you are talking to me, and that bridge isn't staying there! It was only laying there due to the riverwork going on down the line. But thanks for the heads up! I learned that lesson the hard way already by having my articulated locomotives cab's hit the bridges on the way out and into a curve.

I was, I did the same thing and had to make adjustments to my layout so the Big Boy would clear the bridge. I also noticed a black line on one of the walls near a curve where the Big Boy was barely scraping. I had to adjust that section also. I hope to finish my bench work in a couple weeks so I can start to permanently attach the track. I first built the bench work and installed the track to test fit it, Then I removed the track after I finished adjusting all the grades and now I’m putting a skim coat of structolite on top of the foam base and will put a coat of paint on that. I have about twenty feet left to cover.

"That is very sad some people act so rudely in spite of your hospitality. Don't let it stop you from inviting people who haven't visited before."

Not a chance. This was the first time that I can say something like this has happened to me. We love people to visit our layout and that will not change by one unpleasant experience. Thanks for your comments, Mark.

Welcomed grandparents and grand kids to the layout and ran some trains for them. Usually this would be a fun event, but not this time. Rude comments from the adults about "how much money" and aren't you lucky I am not into this" and grabby poorly mannered kids. Not fun. Session ended quickly.

You mean the adults suggested they'd be stealing stuff if they had been into the hobby? If that happened to me, they'd have felt my size 11 boots in an uncomfortable way!

I know a guy who displays a large layout and long ago mounted a handrail down one side. All kids going through must hold the handrail at all times. He swears by it, saying he now realizes kids have to touch something and the rail fills that need. I won't be displaying my On30 layout to anyone not in the hobby that i already know well or anyone not related to my family, so this isn't an issue for me.

As for the theft comment, this isn't limited to model trains. I have a WW2 Jeep and display it at public events, with weapons and gear inside. I get that all the time. A teen once smugly asked what I'd do if he grabbed a .45 semi-auto pistol off my display table and ran off with it. I rotated so he could see the other one strapped to my hip, right next to an original WW1 knuckle fighting knife. Without missing a beat, I said, "If I missed you with all seven bullets from the other one here, I'd run you down and beat you to death with the hilt of this knife." You could have heard a pin drop. He turned white as a sheet and walked away quickly. A older fellow came up to look the display over and said he was a retired guard as a youth prison and said I'd said exactly the right thing and that in his opinion, the kid really was asking what would happen and might have made a grab for it.

finished another Ameri-Town building. I'm really enjoying building them. also have been trying to make a mold of a retaining wall master cast. on 4th layer so far and I still wouldn't pull it off looks too thin. just did the 4th layer with gauze going to do a few more layers to be safe

Attachments

Hello Guys. Tomorrow I will get another 1,000 ft of 18-7 wire and I'll be pulling wire again. I cant beleave how much wire has become. it cost $300.00 just for this amount. I need to get back to work wear I used to scrap this stuff all the time. I also have coming in the mail

Attachments

Laidoffsick,

YOur engine terminal is so nice!

also have been trying to make a mold of a retaining wall master cast. on 4th layer so far and I still wouldn't pull it off looks too thin. just did the 4th layer with gauze going to do a few more layers to be safe

I have made several mold and found mosquito netting at a fabric store works great for the backing. I put about five coats on the master then put the netting on and cover it with a couple more coats. I let my molds dry overnight and only put one coat on per day. It helps if you spray the master with water with a little dish detergent. I found something like the stuff in the milk carton for about the same price. The only difference is it comes in a fifty pound bag. It’s a type of Hydrocal Plaster. I found it at a builders supply center, not Home Depot or Lowes. You can call US Gypsum and ask where their distributors are located in your area. Shipping a fifty pound bag is outrageous. The stuff I bought dries a lot faster than the W.S. Hydrocal. I prep all my molds with the water and soap mixture and mix up a batch in a little plastic paint bucket from Home Depot. I found that the thinner I mix the stuff the lighter the finished product. Bare in mind that lighter is also more fragile.

The hundreds upon hundreds of hours you have doubtlessly invested in this has generated stunning results. It must be very satisfying to be at a stage with this incredible layout when you can enjoy adding detail. The roundhouse is outstanding. I can hardly wait for your next video update. It's been great fun to follow the progress of your project.

also have been trying to make a mold of a retaining wall master cast. on 4th layer so far and I still wouldn't pull it off looks too thin. just did the 4th layer with gauze going to do a few more layers to be safe

I have made several mold and found mosquito netting at a fabric store works great for the backing. I put about five coats on the master then put the netting on and cover it with a couple more coats. I let my molds dry overnight and only put one coat on per day. It helps if you spray the master with water with a little dish detergent. I found something like the stuff in the milk carton for about the same price. The only difference is it comes in a fifty pound bag. It’s a type of Hydrocal Plaster. I found it at a builders supply center, not Home Depot or Lowes. You can call US Gypsum and ask where their distributors are located in your area. Shipping a fifty pound bag is outrageous. The stuff I bought dries a lot faster than the W.S. Hydrocal. I prep all my molds with the water and soap mixture and mix up a batch in a little plastic paint bucket from Home Depot. I found that the thinner I mix the stuff the lighter the finished product. Bare in mind that lighter is also more fragile.

Attachments

Well I can finally say I am done with my plastering today. I was almost done a day or so ago but when I was at the other end of the layout I looked back at the double track tunnel and I had left it too flat on top so over the entrance to the tunnel I added some more pink foam and covered it with plaster wrap and tonight everything is plaster covered. Now I am ready to add the colors to the plaster. But while I was doing that I added two more scale auto racks to my dream train and ran it while plastering. My dream train comes from a real photo I saw of a single CN diesel pulling a string of auto racks Sometimes dreams come true...................Paul

finally wired up the spur tracks for the transfer table and put eh table through its paces and it works fine. then made my first retaining wall from the new mold I created and that worked to so all in all a good day finished off with running my MTH 4-6-0 prr engine pulling 9 centerflow hoppers for the grand daughter to blow the whistle.

also hoping to pick up my first big steamer a lionel tmcc challenger

Started laying wire. Did some feeder wiring, put in the first curve, wider than I'd planned, which is always good...

THEN, I ran the first locomotive ever:

http://vidmg.photobucket.com/a...1034_zps52bbf3de.mp4

Worked on a concept for an O27 trolley layout in RailModeller...

Based on a layout from Linn Westcott's 101 Track Plans. ![]()

Mitch

Attachments

What I did on my Layout Today...............

I cleaned up the work bench, organized tools and installed four Glen Snyder Display Shelfs.

All the B&W prints on the wall were taken by myself and processed in my home darkroom.

See two photos below, Click to enlarge

Attachments

Gary,

Very nice looking room!!

Looks great Garry !!!

Worked on my steel mill today a lot more work to be done.

Today, I worked on my Plasticville Church. I finished painting it and will add lighting and a bell sound chip over the weekend

-Pete

Finally building a 16' long four track hidden staging area. Too many train shows, too many cars!

Today, I worked on my Plasticville Church. I finished painting it and will add lighting and a bell sound chip over the weekend

-Pete

what did you do/use to paint it and make it look like stone/brick? that looks great.

Jrmertz, thank you for the compliment! I used Rustoleum's stone gray spray paint. It comes in a few colors and gives a pretty realistic stone effect.

-Pete

![20140812_021053[1] 20140812_021053[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/12129987997660671/filePointer/34373102093735771/fodoid/34373102093735767/imageType/MEDIUM/inlineImage/true/20140812_021053%255B1%255D.jpg)

![20140812_021053[1] 20140812_021053[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/12129987997660671/filePointer/34373102093735771/fodoid/34373102093735767/imageType/SQUARE_THUMBNAIL/inlineImage/true/20140812_021053%5B1%5D.jpg)