Hi Mark, thanks for asking. There were a couple of reasons I laminated 2 sheets of 1/2 inch plywood together.

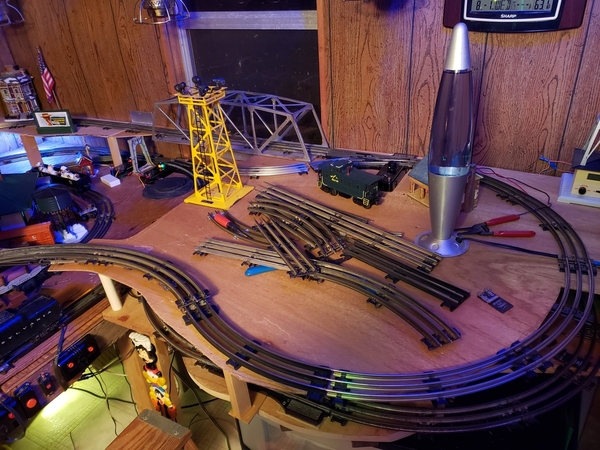

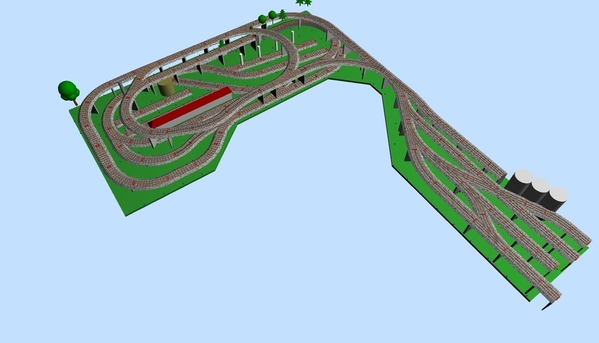

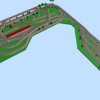

This is the curve that is 180 degrees, probably 8'-6" diameter at the center line between the 2 main lines and it's on a 1.5% grade. So I really wanted the most stable, flat sub road bed I could construct. Whenever I join two sections of roadbed together in a butt joint I end up putting all kinds of reinforcement under the joint. I have used lap joints with more success....

My goal here was to create a long continuous downhill/uphill grade, I didn't want any issues with uneven joints, undulations, and I also wanted it to maintain it's level across the width. This is where the 2 layer idea came from, I figured out I could cut repeated sections 42 to 48 inches in length and overlap the joints top and bottom, so the entire 9 foot diameter is essentially one piece, glued, clamped and screwed together. It worked pretty darn well with very little flexing and was easier to elevate and get the grade right on the money without flexing.... I have always wanted to run pretty long trains 25 to 30 car freight trains, and I figured this curve going up a grade had better as near perfect as I could make it if that was going to work without derailments.

When I was installing it, I made supports for both ends and the mid-point as it was easy to figure out the math for 1.5% grade, then I was able to make sure I was on track for that gradient to get me down to the lower level around the last 90 degree turn across the lift gate. With only 3 support points, it was fairly straight forward to keep tweaking it as the grade continues above and below this 180 degree roadbed.

I ended up adding some oak joists under the roadbed once everything checked out, from top to bottom.

The other reason..... I can't really pick up carry large 4 x 8 sheets of 3/4 inch plywood with the rebuilt shoulder... but I can just about manage 1/2 inch

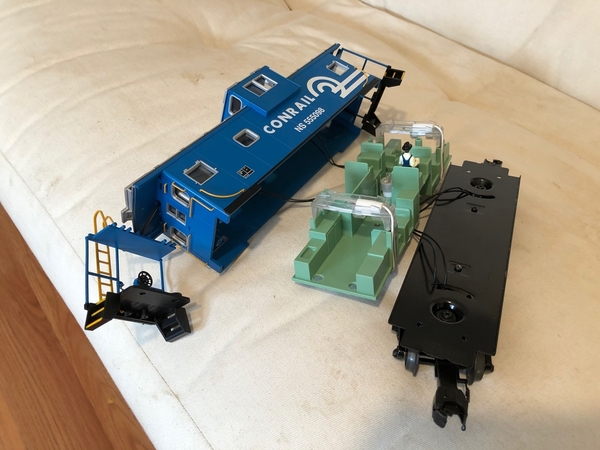

The crew at Vetter Storm and Dash have just received a new drill press and they are transferring it from the Lexington Park and Savannah flat that just brought it in from Milwaukee. The truck will take it around the back to the loading door where she will be set up in the shop and working before 2nd shift tonight.

The crew at Vetter Storm and Dash have just received a new drill press and they are transferring it from the Lexington Park and Savannah flat that just brought it in from Milwaukee. The truck will take it around the back to the loading door where she will be set up in the shop and working before 2nd shift tonight.  The RR maintenance dept got called by the Freight Station crew that the "necessary" needed some repair. So they dispatched a crew to do the job.

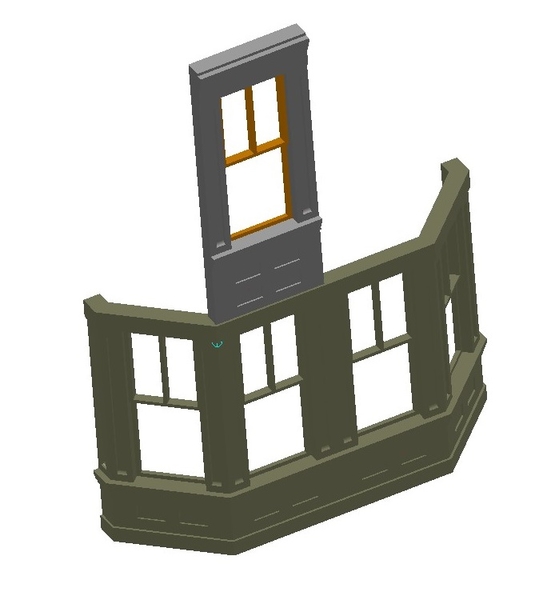

The RR maintenance dept got called by the Freight Station crew that the "necessary" needed some repair. So they dispatched a crew to do the job.