Always have used cork in the past. Woodlands foam roadbed just felt too soft, when I did HO layout years back, so I never tried it. Starting an expansion, cant find any good cork bulk deals, but I ran across this on ebay. 60ft for 32.00. Denser foam than woodlands. Seeing if anyone has/ is using foam, or if the preferred choice is still cork.

Replies sorted oldest to newest

Woodland scenic's foam roadbed.

I used Woodland Scenics foam roadbed for my "portable' layout ten years ago. It is easy to work with and glue and has not deteriorated. It supports our O-gauge engine weights without any "memory" damage. I've even been able to pull up some sections on portions of the layout I couldn't use when I down-sized the layout in retirement. The pulled-up sections are re-useable as well.

I highly recommend this product.

Once upon a time there was someone who made a product called Homabed which was 1/4" Homasote board with 45 degree beveled edges. He also had strips with angled kerfs cut into them that enabled one to bend them around curves. IMO, that was the perfect roadbed material. I built my whole layout with the stuff and still have about 15 feet left over which I'm saving. Alas neither Homabed nor 1/4" Homasote exists any longer. 1/2" is the thinnest sheet that's available these days.

There is a product called Flexbed that's made out of vinyl from a company called Hobby Innovations. Were I to be starting over I would investigate that. I think you can order a sample for a couple of bucks.

EDIT: I stand corrected by Modeltrainparts below. Homabed still exists.

https://cascaderailsupply.com/collections/o-scale

Now, in my experience, I used cork on an N scale layout and Homabed is better. I have not used the vinyl product but I think either would be better than anyone's foam product.

I have used the “Vinyl “ Roadbed under my Atlas Track for years. It is very Bendable & a good sound buffer!

Fredstrains

For what it's worth, when i was beginning my layout about 25 years ago, i sent a couple of bucks to each of the suppliers asking for a sample of their product. I then compared them in terms of looks, cost, ease of installation, etc. I went with Homa-bed for mainline tracks and a sheet of Homasote for my yards and have been more than satisfied with it. Oh, i found no need to seal it with paint, etc on my basement layout. The company has changed ownership a few times (each with a subsequent price increase) and is now available from Cascade Rail Supply.

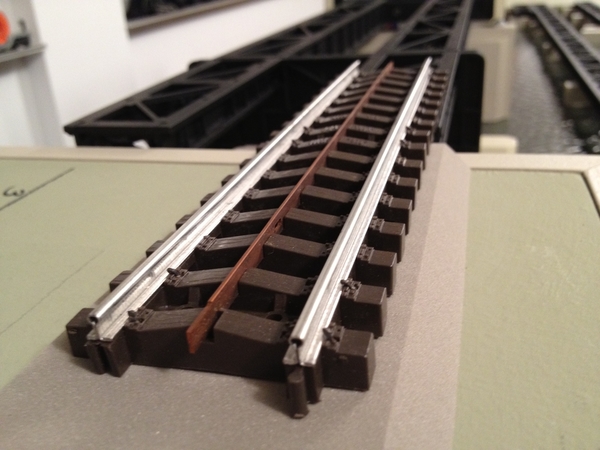

I make my own using acoustical ceiling tile. I cut it to width and then machine the bevels i with a wood shaper. I've created templates for 031, 042 and 072 so far. It works well and we're quite sure that it is quieter than homasote. I use it for my annual Christmas layout on a 10ft X 10Ft runing seven trains. The piece in the photo was dpainted with Stone colored paint that I prrchased at ACE hardware. It really only needs paint on the bevels. The black/white texture of the ceiling tiles is adequate for roadbed for a temporary layout

Attachments

I used cork road bed on top of a Homasote base on top of plywood. The cork and track were painted grey and ballasted with Brennan's ballast.

Your photo seems to be of Hobby Innovation's product called Flexbed. I have used it on four or five layouts and really like using it. It is flexible enough to bend with the track. I place it under the track as I lay it and the screws for the track hole the track and bed in place. It does a great job of sound deadening an looks nice even if you do not ballast. It is much more dense that the Woodland Scenics product which I found to be useless under O track. I never liked having to split cork and either glue or nail it in place.

Flexbed is made in Tennessee by nice people who I have enjoyed working with.

Good luck on your decision.

Happy railroading,

Don

First several layouts (over a period of years) = cork roadbed. Worked well. Recommended.

Current layout being built: Woodland Scenics foam. Easier to work with. Does not "shed" and hasn't become brittle. Highly recommended. ![]()

![]()

Recommend Hobby Inovations Flexxbed as mentioned above. Used on my layout. Easy to work with, bend, cut etc. Great people to deal with, fast, dependable. In my case, used under ATLAS O track. Very quiet.

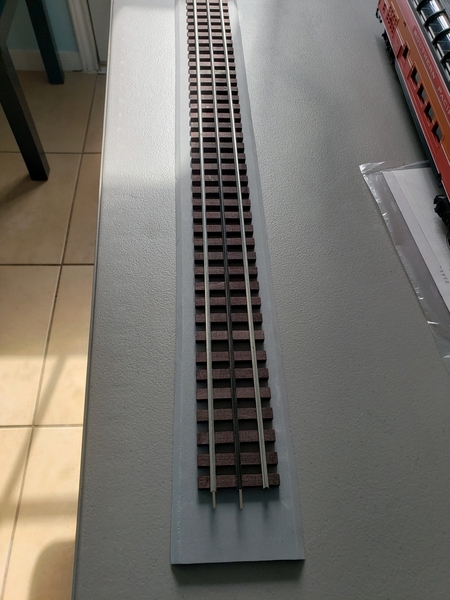

I make my own by carving the 1/2" fiberboard after the track is in place, using a carpet knife. 1/4" isn't tall enough for O gauge.

This is what it looks like ballasted.

Attachments

I use strips cut from anti-fatigue mat found at Lowes in 30" wide rolls. It's approx 3/8" thick and cuts easily with a box cutter and band saw (to angle the edges):

At one time it came out cheaper than cork, haven't compared the two in a long while. I used this last year when I rebuilt my layout (still no scenery!).

Cuts and bends easily, I usually staple it down then use small zip-ties to hold the track in place (holes thru the plywood base).

Attachments

Midwest cork roadbed. LHS carries it, it's cheap, and I'm too lazy to get fancy and make my own.

W&W posted:Recommend Hobby Inovations Flexxbed as mentioned above. Used on my layout. Easy to work with, bend, cut etc. Great people to deal with, fast, dependable. In my case, used under ATLAS O track. Very quiet.

Craig,

You are so right! My Layout was 40 x 50’ W/Flexxbed under Atlas Track. I had 5 Mainlines & 52 Switches, all controlled with Legacy! With Trains running on all 5, it was very Quite! I glued the Flexxbed to the 3/4 Plywood & then (using short screws) screwed the Atlas Track to the Flexxbed, making sure the screws did not go thru the Flexxbed into the Plywood

My recommendation!!!

Fredstrains

Cork

I'll be using Woodland Scenics foam roadbed on my new layout. Have used it in the past with very good results. Easy to work with and to re-position if necessary. Of course, cork roadbed has been something of a standard for years in nearly all scales, and it is excellent as well. I wish I knew how many miles of Midwest Cork roadbed I have used over the years in Z, N, HO, O, and G.

For two rail I prefer Homabed. It is quiet and firm for spiking.

For three rail I have used vinyl bed and also made my own from 1/4" vinyl gym flooring but found it to aggravate precision spiking.

$$$$wise one can not beat cork. The story of cork drying out and getting brittle in my experience is just that, a story.

Lots of creative stories in Border's fiction section.

The present owner of Cascade/ Homabed, is he the same person who made Homabed before California roadbed picked up the line? I have been using Homabed since it was made in New York

I use vinyl under my Ross switches and cork under my Gargraves track. The Ross switch ties are a little thicker than the Gargraves ties. The vinyl gives enough when screwed down to equalize the rail height. Yes, I'm a perfectionist.

Glued vinyl comes up easily if necessary. Cork not so much.

To minimize noise, I stuff the rails with stainless steel wire.

Hal

One of the reasons I think cork roadbed has been so popular is it costs only about 85¢ per linear foot ($63.60/case of 25, 3 foot length pairs of sections for O gauge) which is roughly half that of Homabed and a quarter the cost of the vinyl. Therefore, I think I would amend my original statement and say were I starting over again I'd be hard pressed to use the more expensive products given that kind of price disparity. Then again, there are folks on this forum who don't hesitate to plunk down a grand or two for an engine so to each his own.

For all you Hobby Innovation Flexxbed people - what type of glue are you using to secure your roadbed ???

Thanks

Joe S

Hal, Thanks, I never thought about stuffing wire through the rail heads. What gauge wire do you use?

Being somewhat of a scale operator I run my trains slower then most. I find running three rail trains slowly really reduces the noise and allows the trains to blend better into the overall scene instead of shouting their presence.

Scale modeling can be enhanced by subdued sound, paced movement and soft tones of color.

dorfj2 posted:For all you Hobby Innovation Flexxbed people - what type of glue are you using to secure your roadbed ???

Thanks

Joe S

I use plane old “White” Glue ! It doesn’t take much !

Fredstrains

Tugboat, I have not used foam. In HO, I used cork on top of Homasote. I liked the beveled edge of cork making a nice looking roadbed plus in HO, the nails only penetrated the cork and Homasote so it was fairly quiet. I am using the same on my new O Gauge layout, but bought a box of O gauge beveled cork from a Forum member. I have not checked the availability of buying it new. I only put down cork sheets on my Ceiling Central Railroad only, but did not fasten down the track as of yet because I haven't firmed up the curves. I have thought of using the foam, Flexxbed , but have never tried it.

“Homasote” (real and generic) on my own and our club layout. Mine tubular, club is Fastrack and still noisy! How do you quiet Fastrack? My tubular is very quiet; I have used black screws slightly beyond the Homasote into the OSB beneath but isolated the screws by placing a rubber washer under screw head and vibration less onto ties.

Wally

Thanks for all the inputs. I'll test the foam, once I get it next week, and post my thoughts.

dorfj2 posted:For all you Hobby Innovation Flexxbed people - what type of glue are you using to secure your roadbed ???

Thanks

Joe S

I did not use any glue. I only used screws thru track, roadbed into plywood. Hobby Inovations foam easy to work with, easy to bend around curves. Whenever I take layout down, the foam will be easy to remove due to NOT gluing. I prefer to eliminate using glue on my layout, if possible.

Craig, I am getting to come to the conclusion you are. Don't glue as much as I used to. So many things just don't need it, and it makes it easier to fix my mistakes.

Tugboat15 posted:Always have used cork in the past. Woodlands foam roadbed just felt too soft, when I did HO layout years back, so I never tried it. Starting an expansion, cant find any good cork bulk deals, but I ran across this on ebay. 60ft for 32.00. Denser foam than woodlands. Seeing if anyone has/ is using foam, or if the preferred choice is still cork.

WILL YOU PROVIDE A LINK TO THE INEXPENSIVE ROADBED---IF THE FORUM DOESN;T WANT THAT PLEASE EMAIL AT MY ADDRESS IN MY PROFILE --THANKS

Tom Tee,

I use 18 gauge, galvanized steel available in 110' lengths from Lowes (maybe Home depot?).

Hal

I'm still obsolete--always used Midwest cork except in Yards and on rural spurs/sidings. Always tried to lower those sidings down into the dirt somewhat as compared to a raised mainline profile.. Used Gargraves Flextrack since 1992---it enables flexible layout decisions![]() .

.

Most cork is fine, but some cork drying out isn't a myth. Why, I have no clue.

From N.O.S. automotive gaskets to unused pin board, I have seen it myself. E.g.,.. 2 valve cover gaskets in the same Mopar box; one nearly as stiff as wood and "dry-white", the other still supple and brown. I've tossed cases of stiff nos VW gaskets at work too.

Rare maybe, but not a myth.

I like to reuse things so I lay all my track first. Then I slide one half of cork under the track and secure with atlas nails every so often on the edge just enough to shape it to the track work. The other half of the cork goes in place very fast. I then screw the track down as usual thru the cork and into the tabletop and that finishes off everything. If I change my route months later all comes up with no problem. No glue for me. Sound is no problem.

No roadbed. I have green paper mat down, put track right on top, works good. Save money not using roadbed. ![]()

Cork. One of my layouts was started in 1999. The cork roadbed looks like new.

MELGAR

BeerTrain:

This is where I got it from.. If this gets deleted, I can email you the link. I cant get into my email at the moment. Can choose between grey and black.

Tugboat15 posted:

I also used and like this. I found it very good for the price though it's under ballast now so no photos.

I would stay away from any soft foam road beds. I bought a bunch of it at a great deal and it caused nothing but problems getting my track to ballast correctly. I ended up ripping it, out track and all and used the rest of it to insolate doors and windows.

I like Homosote, deadens the sound, good firm surface to work with, provides a solid surface to work with and strong enough to screw into.

Just remember not to screw through it into your plywood sub base. I leaned from one of Jim Barret's how too articles that the sound vibrations will travel through your fasteners into the plywood defeating the whole purpose.