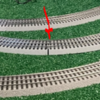

I strongly second the advice about checking the distance between the two track curves.

When I finally finished my initial layout, including gluing and screwing everything down, I found that there was one tiny spot where two curve pieces were too close to each other, by about a half an inch. When running my large engines, it was no problem if they were running side by side in the same direction around those curves, but when they ran in opposite directions, the front edges of the engines would clink together and derail if they hit those curves at the same time.

Nothing I could do about it. So, it is just one trouble spot in the layout where I have to be careful what I am running and in what direction.

So, before you start gluing and screwing, check and adjust those curves. You may not have to add an extra foot to the width of the table, and perhaps something as small as an extra 4 inches of width may do the trick. Test now, not when it is too late. :-)

You don't have to wire it up to test this. Hand place your biggest engines and slowly hand- push them around the curves.

Mannyrock