John what transformer do you prefer?

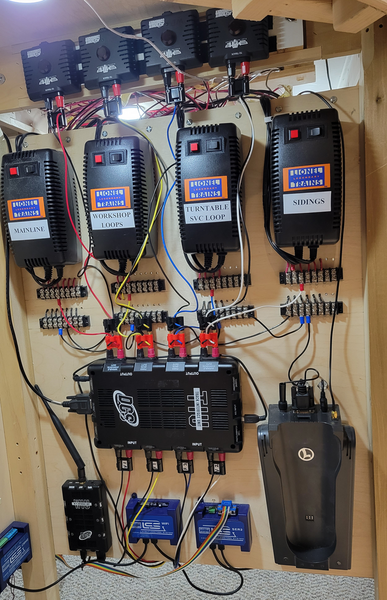

Not trying to answer for John, just trying to explain my take on what I know he uses (Lionel 180 watt Powehouses).

First I think the 180 Watt Powerhouse bricks are a great power source. They have an excellent built in circuit breaker. They output right on 18V and do not sag under typical loads any appreciable amount.

The catch22- they are not variable output devices. You have to put something in between them and the track if you want variable. Second part in most variable voltage conventional setups is bell and whistle DC offset buttons for activation. Add into the mix, you want to remotely control this via some form of handheld remote or even say an app on a phone or tablet device.

On the big "L" side of the house, you have the Legacy Powermasters, the TPC300 or 400, older original Powermasters.

Pros of those devices- made or intended to work well with the 180 watt power house. They also probably would be stiff and not sag because of the way they control and vary the power output.

You also have the ZW-C, ZW-L, GW180 transformer types.

One could throw in the MRC Pure Power series while at it if you needed a large 180 watt class variable power source and does conventional bell and whistle with diodes.

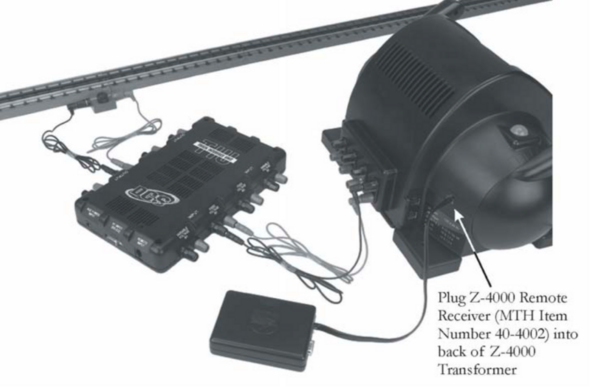

On the MTH side, you could use TIU variable channels to modulate a fixed input voltage for conventional operation (also does bell and whistle offsets).

Again, here is my thought process regarding the typical layout and daily usage:

You should turn off the track power before placing trains on the track or removing them. Do you slam that power on/off with a relay or power switch, or ramp up the voltage with a variable voltage source?

Do you run conventional trains or maybe one day have the need or desire to?

Might you ever have an MTH PS1 engine that has some more specific power requirements (example smooth sine wave) that also may need programming or reset?

Do you want to remotely be able to turn on and off an individual track or output or run conventionally via remote control?