Nick,

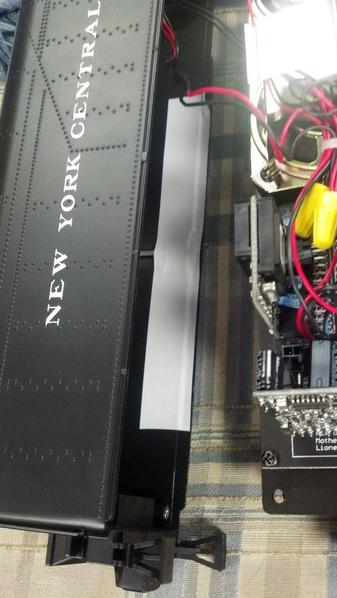

I have the exact engine with the exact same problem. There is nothing in the interior of the tender that is loose or rattling. What is making the noise is the tender shell itself that is vibrating. With the volume up high it seems to excite the natural frequency of the shell. I tried using the dense foam from the ends of lionel engine boxes as a brace from side to side with little effect. As with you if you just lightly pinch the outside of the tender shell the vibration stops. Possibly a gasket at the plastic shroud to the tender base may help,but I am thinking about changing the natural frequency of the tender shell. Maybe one of those HO self stick lead weights on the inside of the tender shell to change the sprung mass.

Let me know what you find works. Also, thanks for the tip in the other post on the boxpok drivers. I had been under the impression the engine was supposed to come with these. I was surprised to find them on the Lionel parts site and ordered them up. What a pleasent difference.

Thanks,

Greg