Holy cow...that is some really nice work...and a cool prototype, too. 👍

Mark in Oregon

|

|

Holy cow...that is some really nice work...and a cool prototype, too. 👍

Mark in Oregon

JJ, exquisite!

PFM did the E6 4 6 0 ,, but my Gfather mentioned to me 40 years ago that when he was a kid in Seattle about 1909 , he decided he "owned " engine 1053-an E8. Looking into it, the E8 had 73 " drivers compared to the E6 with 63. Drawings were not available . I pieced together what I could from the Minneapolis historical society from bits of drawings of other E class and some F and G , all made about the same time . Just putting 73 " drivers on an E6 won't do because the Boiler is higher, so the domes and cab are shorter . Also, the 8 s were a little longer and heavier . They were dragging around the 'Fast Mail' --maybe even the early 'Flyer' (what a name !) until about 1910 when train weights increased . They survived on the locals with number 1053 dodging the torch till 1947.

They were all made by Rodgers . 10 in 1902 & 10 in '04 . although both dumped into the E8 class, the earlier batch seemed to have higher domes . my model is of the earlier . Me personally, I think they were as delivered , the best looking engine. And must have been quite a site with the wooden 'Fast Mail' or 'Flyer' at 60 mph.

Excellent craftsmanship!

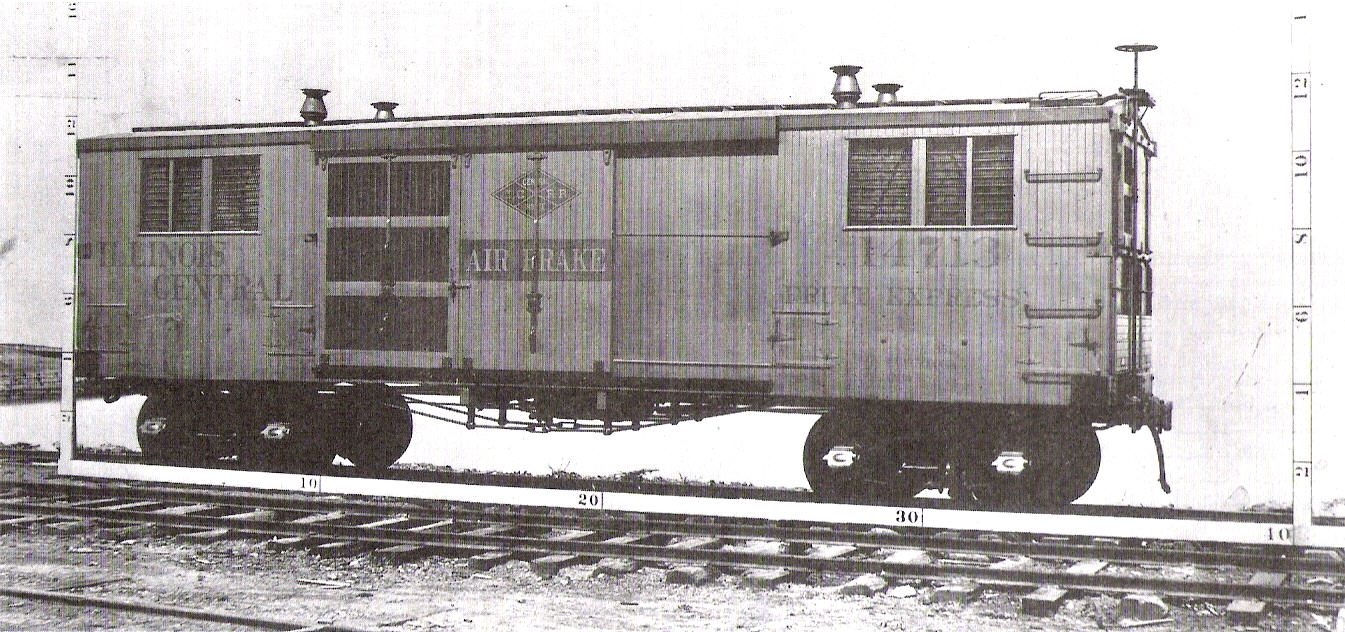

Train Craft Caboose

I do like that one!

Martin,

That is a super nice caboose. Great work! Ive got a couple of Traincraftcab kits, both are bobber cabs.

Malcolm

@Brother_Love posted:Martin,

That is a super nice caboose. Great work! Ive got a couple of Traincraftcab kits, both are bobber cabs.

Malcolm

Do those bobbers come with the truck hardware?

The frame for the Lobaugh J&L tank car is substantially complete. I've yet to add the rivet heads for the poling pocket castings and the holes for the brake wheel staffs on both ends.

Seeing the pictures of the full-scale car disclosed that Lobaugh's kit is only an approximation of the real thing. Differing most is the construction of the tank support cradles. Lobaugh has the tank bands outside the cradles; the real car has them inside. The visible vertical structure around the bands is completely different. Lobaugh's drain valves are different, and the supplied brake components aren't even close. It would take some major modifications to replicate the original, so I decided to just build the kit - more or less as it is.

Assembling and soldering the many brass parts was not as difficult as I expected. Two ongoing problems were experienced - minimizing the amount of excess solder and keeping the pieces straight and in alignment. I used my Weller 200 watt gun, an 80 watt iron and my home-made resistance solderer. In most cases, bigger was better. If I could get the tip in good contact, the highest watt tool was used.

The resistance solderer is very good for the small parts and generally good for attaching small parts to large pieces. Sometimes the internal circuit breaker in the battery charger would trip before the parts got hot enough. It's a 10 amp charger which showed about 15 amps being pulled when on the full dimmer setting. I learned that if it tripped, I could cycle the foot switch to be on for no more than a count to 10. A couple of pulses like that gave me the heat to complete the job.

I did try to replicate the brake components to be more like full scale. I turned some simple cylinders and air reservoirs and added the lines and rigging. Every touch of the frame and every solder job causes more tarnish. I'd like to know how those who build these things keep the brass shiny.

Next up is the tank.

Jim

Jim, your underbody detail looks fantastic . I use very small diameter solder . I also got one of those cheap draw plates on ebay and it works to reduce the diameter of regular solder. Some parts I presolder and if I get too much on, just file the excess off before assembling . A toothbrush and compound or just some tarnish remover. don't leave acid flux on --Oh, and coat your steel tools with WD 40 each day to keep stray flux from trashing them too. (then wash hem before use with acetone to keep from transferring the oil to brass parts.)

Thanks for the comments and tips JJ. I sometimes use a process I saw on the internet. Solder is hammered flat to the point where it is paper thin. Small bits can then be cut with an Xacto knife and either inserted between the fluxed parts before soldering or positioned right along side the joint. I'm applying flux with a hypo; the paste keeps the solder bits in place (usually). I also use the tin both joints first method. I like the paper thin piece between parts when using the resistance solderer. That's what I'll try when the time comes to attach the walkway brackets.

A concern is whether I can generate enough heat to sweat the tank ends and domes to the shell. I am still contemplating whether I can use my oxy-acetylene torch for the job. I've got a small torch and need to see if I can get a soft enough flame so as to not end up with a banana shaped tank. Other methods first - to be safe.

Oh, yeah, I forgot about thinning out the solder and cutting bits. Now, thinking about it , use very clean hammers and surfaces or contaminates will be transferred to the solder. The hand rail brackets are perfect for presoldering . I used a like method for adding grab iron nbw detail that I described in a drawing--if I can find it I will add here. The ends to the wrapper sounds like a regular butane torch job. The ox/ac I'm sure would work so long as the heat was not concentrated. I guess you have learned as I did that hitting fast with the most power keeps heat from migrating before you can cool it --HAHA I slumped a whole cab learning that ....You are going to have a great car and one that you can be very proud of. all the models that I have told the kids not to sell when I croak are the ones like this . The premade brass is fine, but not the same . regards, JJ

Jim, on the tank, I would pre solder the inside ends of the wrapper , clear off excess, then assemble it to the ends with radiator hose clamps then hit the ends only with a plumber's butane torch.

I found the drawing I made about adding grab iron ends , but it does not include the step of preordering and clearing excess. the attachment with resistance like you are doing was a breeze. I had posted this somewhere else , so if you have seen it before please excuse. Jj

Ambroid bash. Kiel line 6 wheel passenger truck with the center journal hacked out . A piece of 1/16th k&s square tube connected the equaliser

@Brother_Love posted:Brass side frames.

They came with the brass side frames???? Wow!

Or, are those something you've added into the build? If so, where did you get them? I need a set or 2.

@mwb posted:They came with the brass side frames???? Wow!

Or, are those something you've added into the build? If so, where did you get them? I need a set or 2.

They came with them.

@Brother_Love posted:They came with them.

Interesting - my kit lacks them in any form........and the cupola packet, too. Time to improvise.

I’ll never get around to building but I’d trade it for a AN ventilated boxcar😉

@Brother_Love posted:I’ll never get around to building but I’d trade it for a AN ventilated boxcar😉

Those are hard to come by and sell surprising high.

I'd suspect that if I can scratchbuild copies of them fairly easily in wood that your styrene skills should make such a project very approachable. Also, given that Clover House sells dry transfer lettering sets for several roadnames and variations of ventilated cars that you could have even more fun building some of the lesser seen versions and have some really unique cars.

Malcolm,

You have one scheduled for delivery today. With your skills you should be able to make all you need easily enough.

Jay

@Jay C posted:Malcolm,

You have one scheduled for delivery today. With your skills you should be able to make all you need easily enough.

Jay

Yes, can’t wait to get started on it. After I build it I may go the styrene route. I need 4-5 of them. I also have acquired some drawings from a Ambroid kit and a couple of pics were sent to me also. I still have not been able to locate a pic of one in Illinois central paint.

I'm willing to wager they would be well received and desired by many. Just sayin....

Jay

...and just think, no cupola, or other caboose bits, to deal with.

Jay

""You have one scheduled for delivery"' Jay , yer a peach !!!

""I need 4-5 of them"" Malcom, yer, uh , yer a , well, ... In kinda deep. ( But keep up the splendid work ) :<![]() --JJ

--JJ

@J J Davies posted:

Wow! Great pic of a really early VB. Thanks for posting.

This page from a 1952 Train Craft ad, shows what they had available at the time. The kits seem low cost by today's standards, but a four wheel caboose kit for $5.00 was a good bite into one's average weekly pay at the time.

I was 14 then, and used some of my hard earned lawn mowing money to buy the center cupola kit at a hobby shop. Dad criticized my wasteful expenditure on it. The caboose in this photo was it, originally built from that Train Craft kit in 1952. It was re-done to this appearance in the-mid 1960's, with new Northeastern scribed siding, new paint, lettering and a pair of markers. The R&N was for "Richmond & Northern," a model railroad name.

Then in the 1990's, this prototype photo of a B&O K-1 caboose on Staten Island, still with its cupola in 1940, was found. I saw them like that when I was a boy.

In the 1990's I dug it out of a storage box, nearly forgotten. What to do with it? I had already scratch-built a B&O K-1 four wheel caboose with underbody and interior details as a model for an NMRA award.

So back to the work bench again, for a re-build, new details and a prototypical paint and lettering job. I had almost junked the Train Craft car, when I found an E-bay add for a set of original Train Craft B&O style caboose steps. A hobby shop in Hungry Horse MT was closed out and selling off old stock. I became a good customer for a while, finding O scale NOS items from the 1940's and 50's.

All done in the prototype; 1940's appearance in B&O freight car brown, which was their caboose color before 1942. It would lose the cupola by 1943 and by 1949, it would be wearing a fresh coat of B&O Devils Red with yellow grab irons.

As it stands now, it goes very well with my SIRT 0-6-0 camelback switcher which 'grew' from a brass Locomotive Workshop "Economy 0-6-0" kit. The flat car is from a Liberty Models kit, specially run for the Mid-Continent Region, NMRA 1972 convention that I modified to be a M of W car. Oh - Hey Dad, I still have that expensive caboose I bought in 1952!!

S.Islander

Great story! Fantastic modeling! Awesome looking B&O Bobber!

@Santa Fe Forbes posted:Great story! Fantastic modeling! Awesome looking B&O Bobber!

I agree on all counts... 👍

Mark in Oregon

All construction is complete on the Lobaugh J&L tanker. Next will be to clean and degrease, then primer and paint.

Building this kit was an interesting experience. It made me fully appreciate the skills that locomotive builders must have. The biggest challenge was to keep everything plumb, straight and in alignment. Try as I might, there are areas where I just could not do it. Parts have a tendency to move before the solder melts, then stick just where they shouldn't. I used all my soldering tools and relied on my home-made resistance solderer for most of the small parts. Interestingly, it did not generate enough heat the solder the grab irons to the thick tank ends - I broke down and resorted to epoxy. For the heavier parts the 80 watt iron and Weller gun were used.

I debated for days whether to buy a small butane torch to sweat the domes to the shells. Figuring I'd never use the torch again, I decided against it and tried the 250 watt Weller gun. It worked. The dome profiles don't exactly match the tank diameter, one of the few areas where the Lobaugh parts aren't quite right.

As mentioned earlier, the plan was to build the kit pretty much out of the box and using the Lobaugh parts. Deviations were the addition of simplified brake gear approximating the full scale and the top railing, constructed with the Lobaugh wire, but also a little closer to full scale. Not yet added is the retainer piping.

The Lobaugh coupler pockets were retained but lowered so the top opening was at the correct height. The frame received a shim piece so the coupler would mount at the opening height. Kadee 805 shanks were cut off, brass plates added top and bottom, pinned to the coupler body. The gap inside was filled with JB weld and drilled for the mounting hole. This description probably makes little sense, but the result is a short shank coupler the swings a bit and fits the Lobaugh parts.

Here are a few pictures.

Jim

Very nice. I personally would find Lobaugh trucks for it. Glad you preserved the Lobaugh coupler area.

I have been there and done that. I admire you for sticking with the project. Great looking tank car!

Jim- excellent job . I doubt that one in one hundred of these kits were completed as nice as you have --Let alone completed ! Now you have something you can really be proud of .

Over the years I've seen a lot of the Walthers PRR N-5 cabin cars around. They are not an easy model to build and results have been all over the place. I picked up an unstarted kit and decided to try my hand at building a decent model if possible. Here are the results. Car rides on a prototypically correct set of PRR single coil trucks in brass I had picked up at a train show. Decals are Middle Division. I decided to add the reinforced ends the Pennsy added to most of their N-5's in later years using brass. I uderstand it doesn't meet today's technological standards, but I thought it pretty nifty for a 1940's offering. I believe the project shows you can make a decent Walthers PRR cabin car if you are willing to put in more time and effort than you probably should!

Very nice. Great paint and decals!

Nice cabin. Some incentive to give my Walthers one a redo. I purchased this as shown about 10 years back. Not a bad build, just out of era for my 1955ish goal for my NY&LB modeling.

Access to this requires an OGR Forum Supporting Membership